Device for mixing dyeing material solution

A mixing device and dyeing material technology, applied in the field of machinery, can solve the problems of difficult control of printing and dyeing auxiliaries, manual addition of printing and dyeing auxiliaries, high labor intensity, etc., to achieve small deviation, clean inside of the frame, and fast disassembly and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

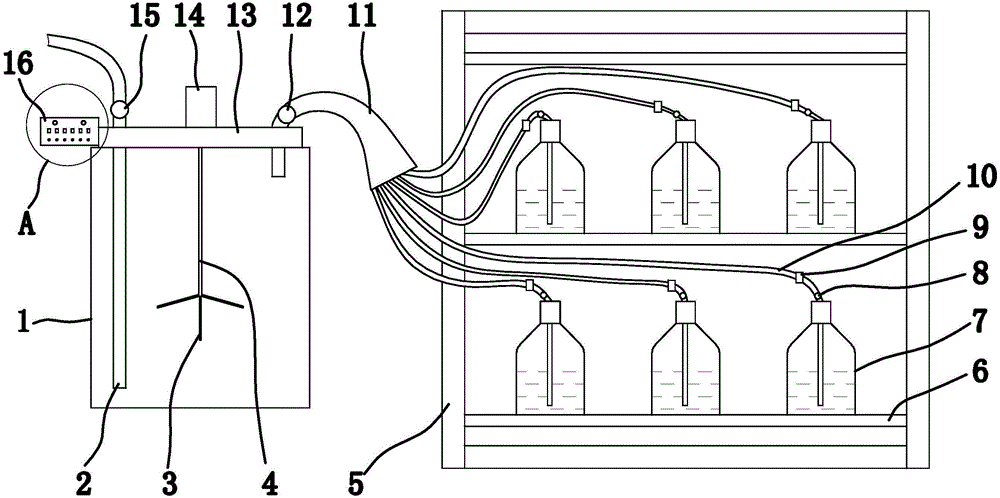

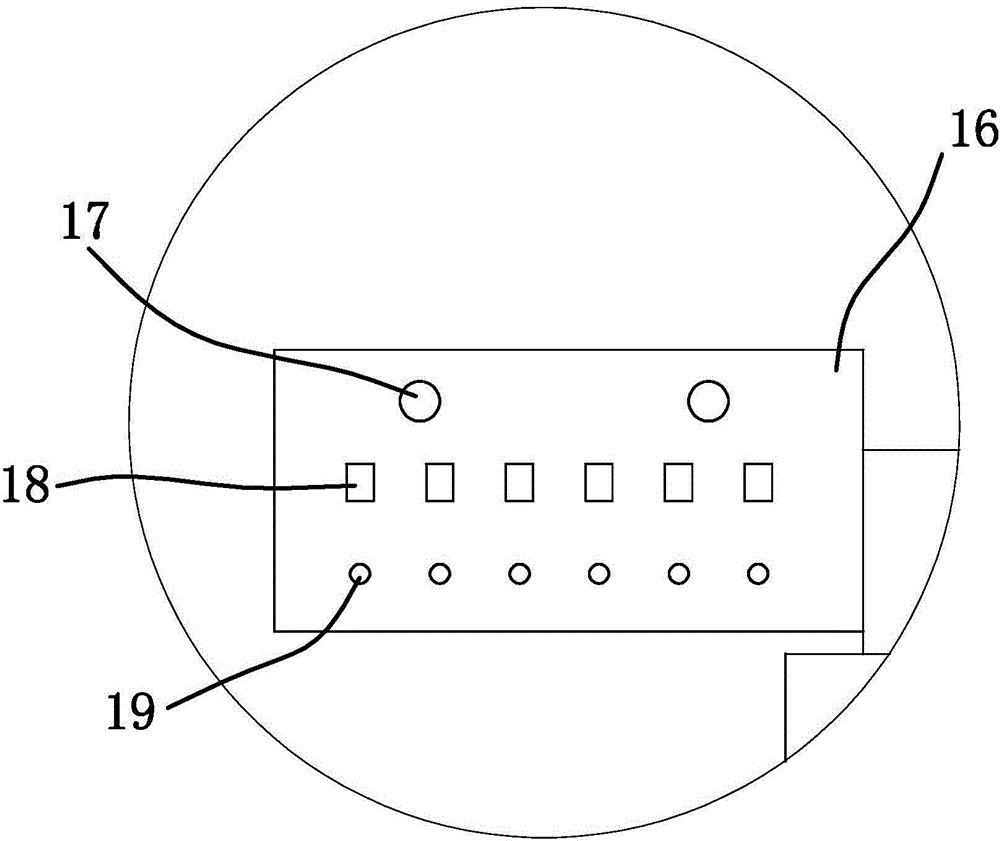

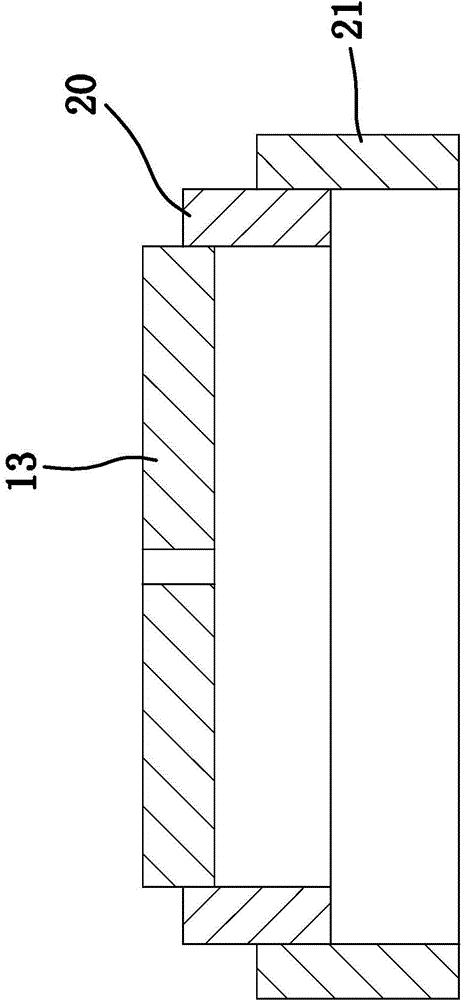

[0041] Such as figure 1 As shown, the mixing device of the dye solution includes a barrel-shaped body 1. In this embodiment, the body 1 is made of stainless steel to ensure that it has a long service life; the upper end of the body 1 is open and in the Its opening is connected with an end cap 13, and a mixing chamber for mixing the dye solution is formed between the body 1 and the end cap 13. It also includes a mixing mechanism, a feed pipe 11, a discharge pipe 2 and a stirring mechanism. The inner end of the material pipe 11 is located in the mixing chamber, the outer end of the feeding pipe 11 extends out of the mixing chamber and is connected with the mixing mechanism, the inner end of the outlet pipe 2 is located at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com