Ore grinding device

A technology of ore grinding and dehydration equipment, which is applied in the direction of grain processing, etc., can solve the problems of difficult to achieve water balance and low pulp quality, and achieve the effects of reducing consumption, increasing efficiency, and ensuring the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

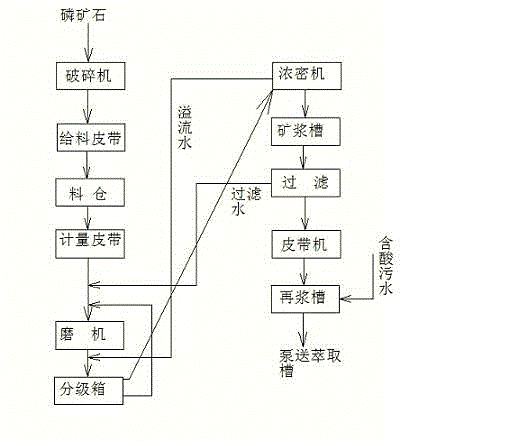

[0007] Combine below figure 1 , the present embodiment includes a closed-circuit device, and the closed-circuit device is connected with a secondary dehydration device; the secondary dehydration device includes a filter, a belt conveyor and a resizing tank; the filter is connected to one end of the belt conveyor, A water pump is provided on the filter, and the water pump is connected with the water inlet pipe of the mill in the closed circuit device; the pulp inlet of the re-sizing tank is connected with the other end of the belt conveyor, and the water inlet pipe is provided on the re-sizing tank; After the slurry tank, filter equipment is added for secondary solid-liquid separation, so that the content of the slurry is reduced to less than 20%. The separated wet mine is transported to the re-slurry tank by a belt conveyor, and diluted with acid-containing sewage to a solid content of 65%. %, and then pumped into the extraction tank for reaction; the water separated by the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com