Hydraulic machine with multi-housing multi-directional bearing racks

A hydraulic press and archway technology, which is applied in the field of hydraulic presses, can solve the problems of easy breakage of connecting parts, difficulty in using large-tonnage hydraulic presses, and increased overall weight of the frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

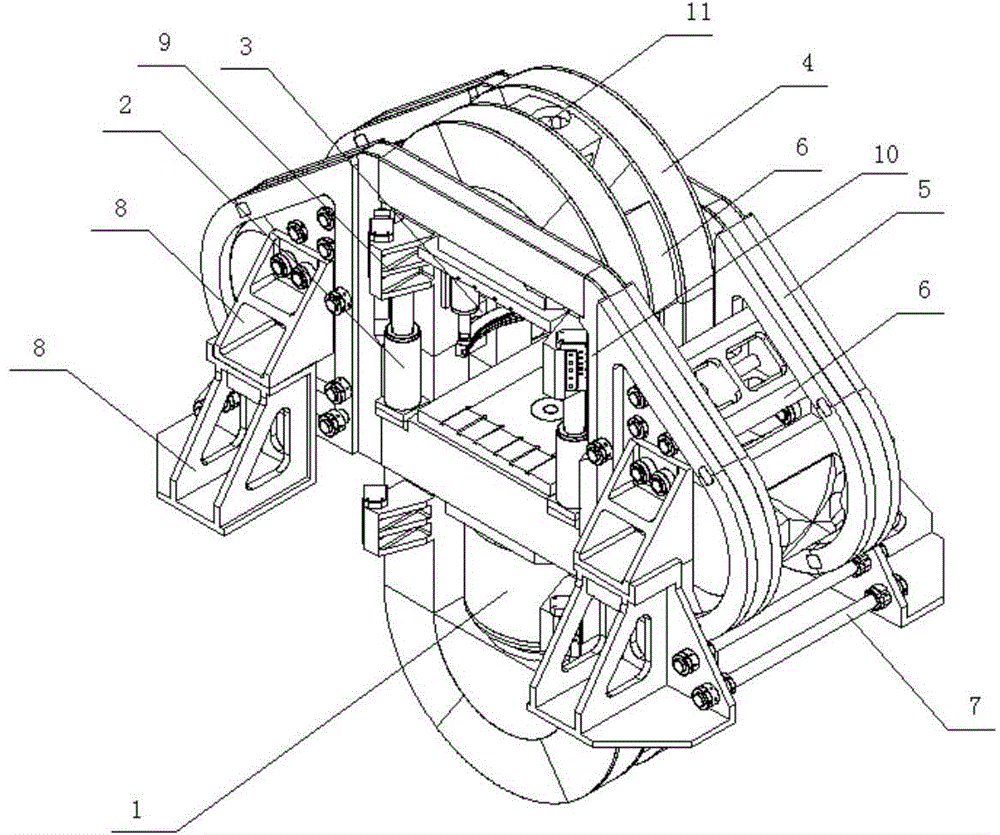

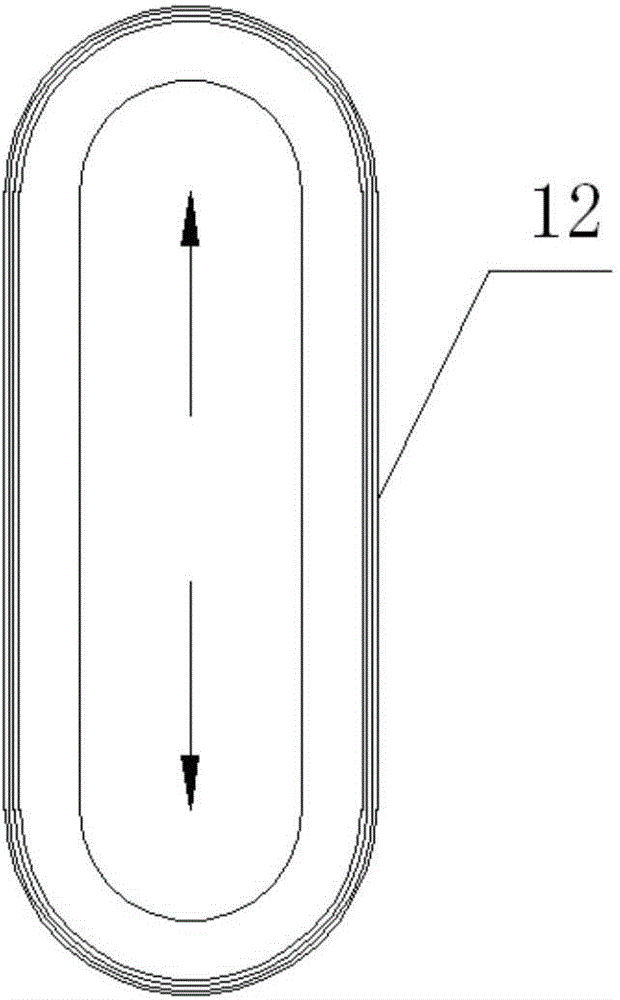

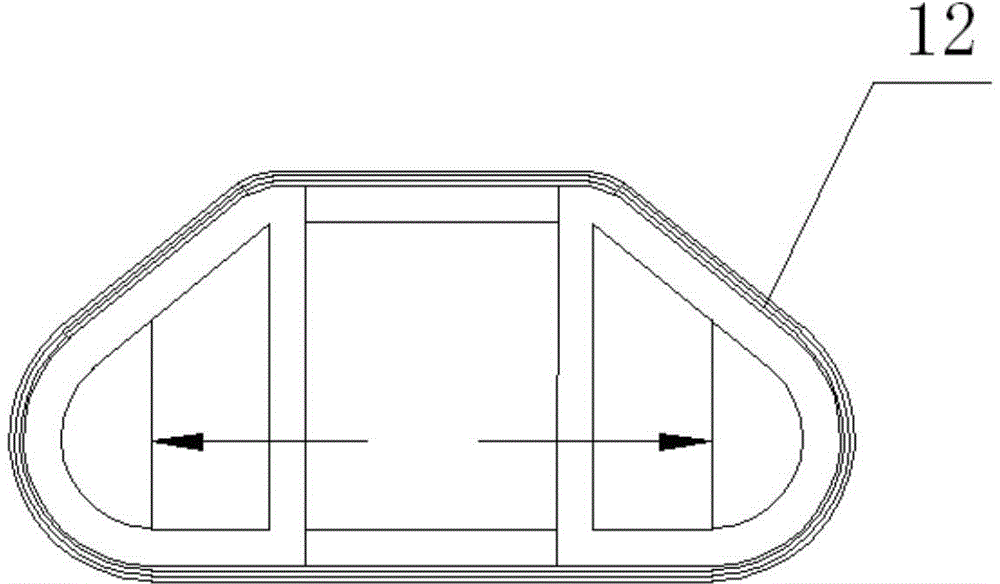

[0016] Embodiment: A kind of multi-arch hydraulic press with multi-directional bearing frame, including at least two horizontal frames of single arch, at least one vertical frame of single arch, main working cylinder 1, return cylinder 2 and horizontal cylinder 3, at least one single The vertical frame of the archway is arranged in parallel and fixedly connected together to form a multi-archway vertical frame 4, the horizontal racks of at least two single archways are arranged in parallel on both sides of the vertical frame of the multi-archway, and the horizontal frames of at least two single archways The frame is fixedly connected together to form a multi-archway horizontal frame 5; the multi-archway vertical frame can slide vertically relative to the multi-archway horizontal frame 5; the multi-archway horizontal frame 5 is located on the multi-archway vertical frame The part in 4 forms a horizontal work surface, and the cylinder bodies of two horizontal cylinders 3 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com