Nailing machine of steel-structured plates and nailing method thereof

A technology of steel structure and trigger, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of insufficient automation, low production efficiency, and affecting the process of industrial assembly of integrated houses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in combination with specific embodiments.

[0029] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

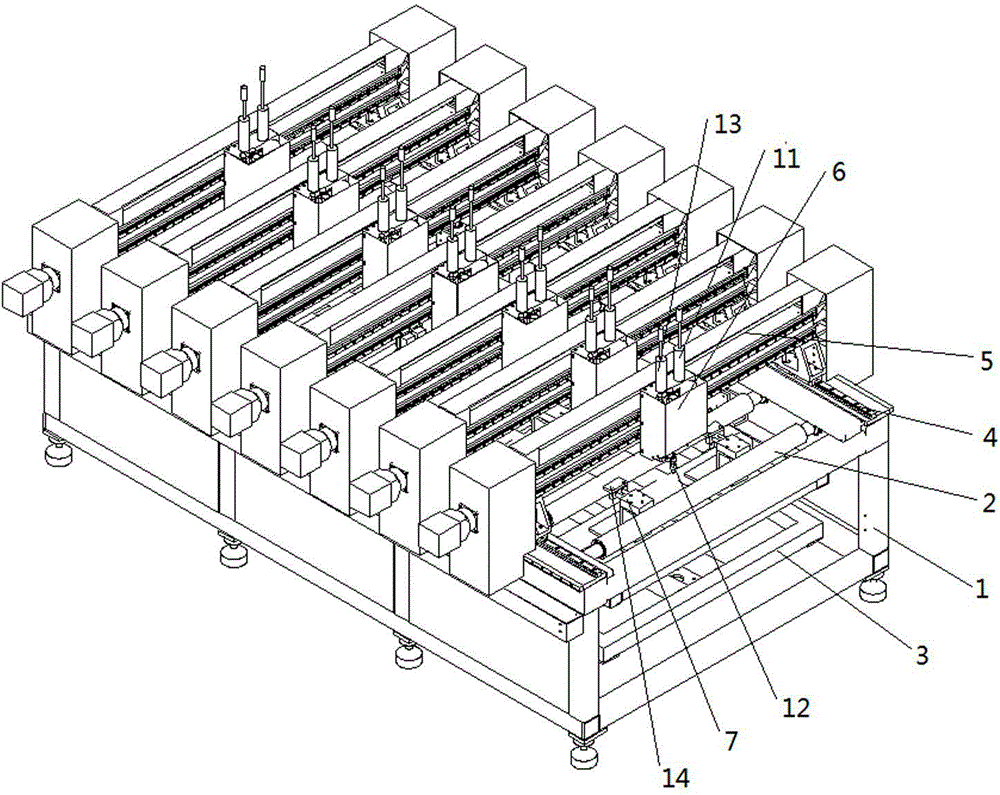

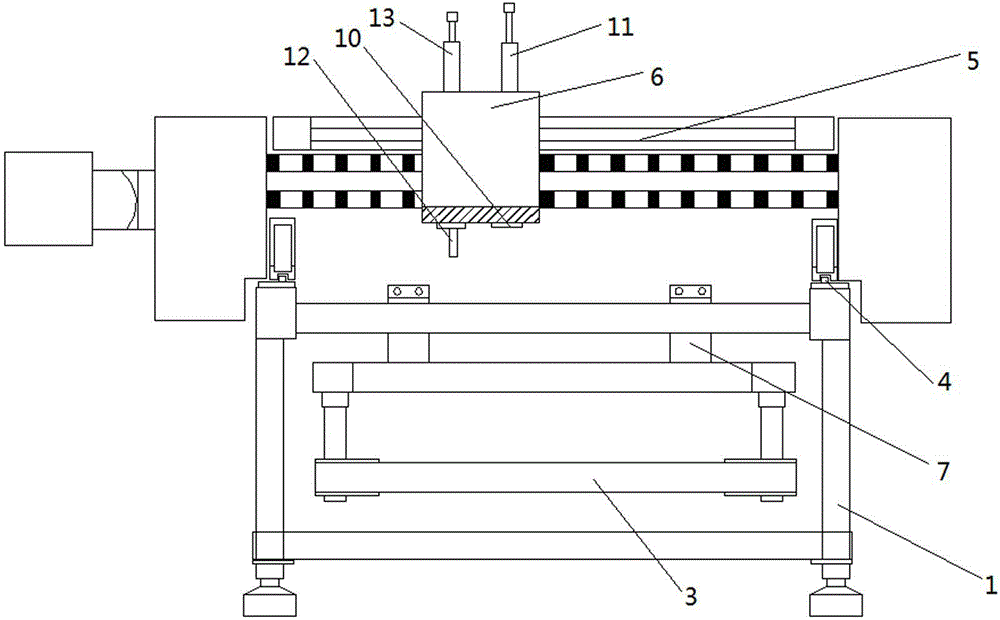

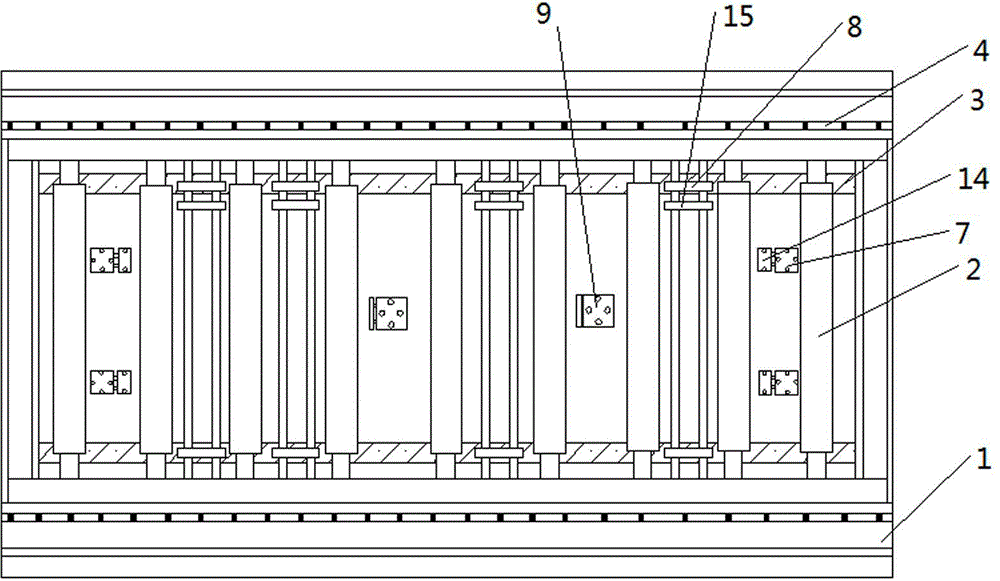

[0030] Such as figure 1 Shown is a three-dimensional structure diagram of a preferred nailing machine of the present invention, including a base 1, a conveying device 2, a floating device 3, a sliding guide rail 4, a beam 5, a drilling and nailing device 6, a positioning cylinder 7, and a drilling control head 11 The nailing cylinder 13, the cylinder 11 that controls the vertical movement of the pressing rod (not shown in the figure), and the pressure plate 14 used for the front and rear positioning of the steel frame, wherein a plurality of beams 5 are distributed on the base 1 in parallel, and pass through the sliding guide rail 4 connected, and can move along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com