Revolving table device

A technology of rotating worktable and rotating platform, applied in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconvenient maintenance, reducing the service life of various components, affecting processing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make your review committee members have a further understanding of the present invention, the preferred embodiments are hereby given in conjunction with the drawings, and are described in detail as follows:

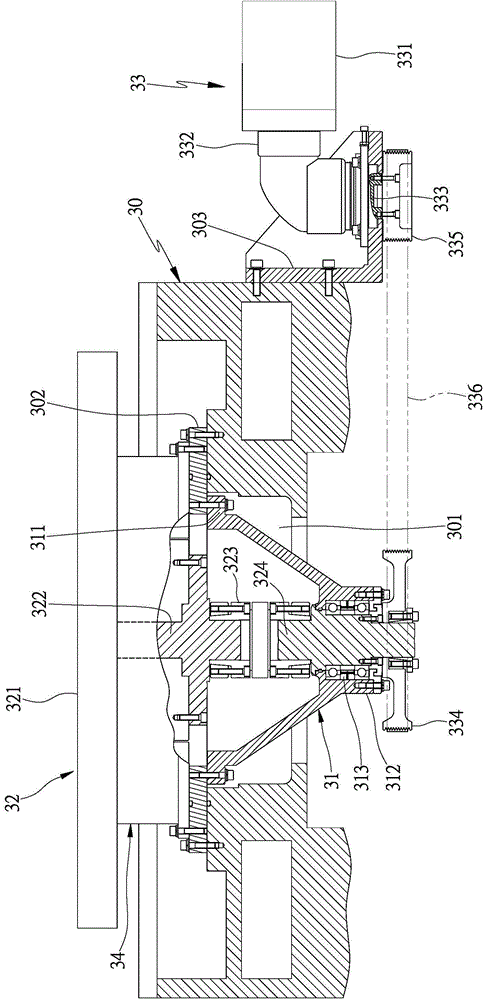

[0041] see image 3 The rotary table device of the present invention mainly includes a pedestal 30, a support ring body 31, a rotary platform 32 and a rotary drive mechanism 33. The pedestal 30 is a body, and a space 301 is provided inside for mounting the rotary platform. 32. An inverted cone-shaped support ring 31 is fixed in the insertion space 301 of the pedestal 30. In this embodiment, the large-diameter end above the support ring 31 has a connecting seat 311, and the small-diameter end below is There is a support seat 312 for installing a bearing group 313, and the support ring body 31 is locked and connected to the pedestal 30 above with the connection seat 311. In this embodiment, the pedestal 30 is first locked with the connecting plate 302, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com