Dry-mixed mortar production line

A dry powder mortar and production line technology, applied in control devices, batching weighing instruments, mixing plants, etc., can solve the problems of inaccurate proportioning, high energy consumption, low efficiency, etc., achieve accurate measurement, low energy consumption, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

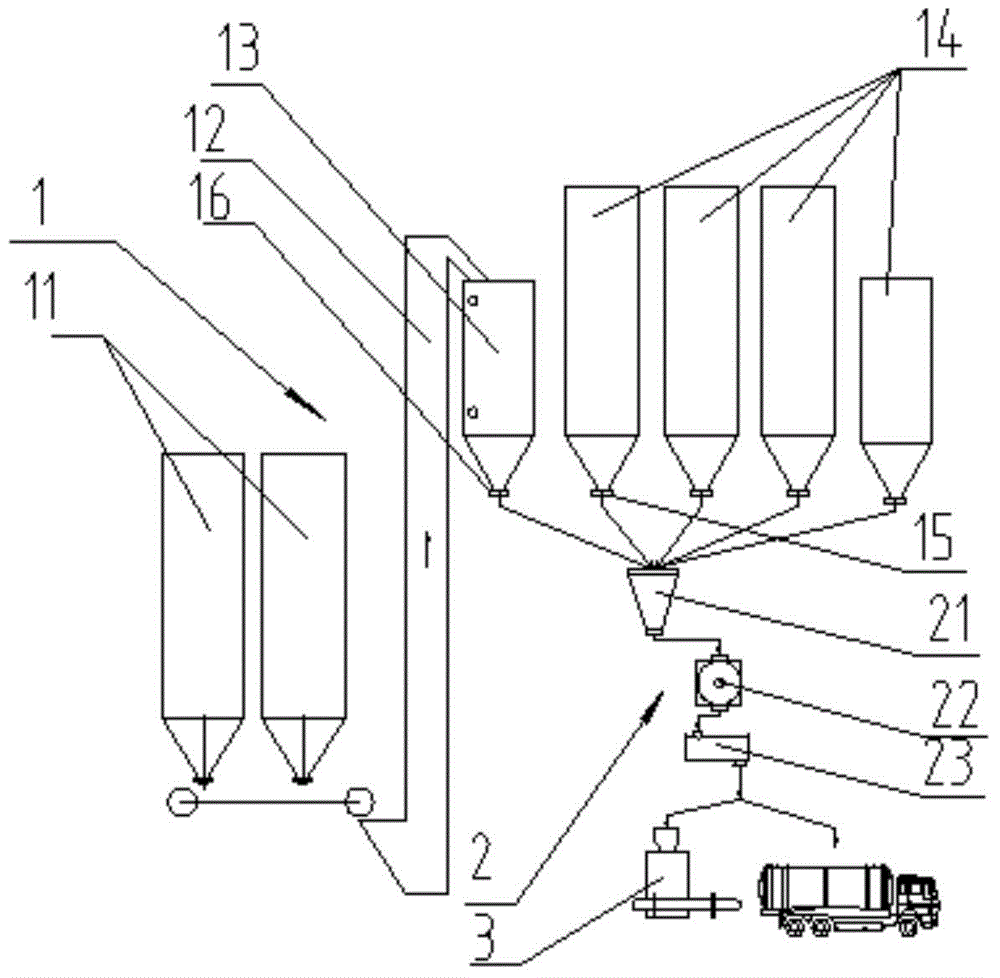

[0032] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

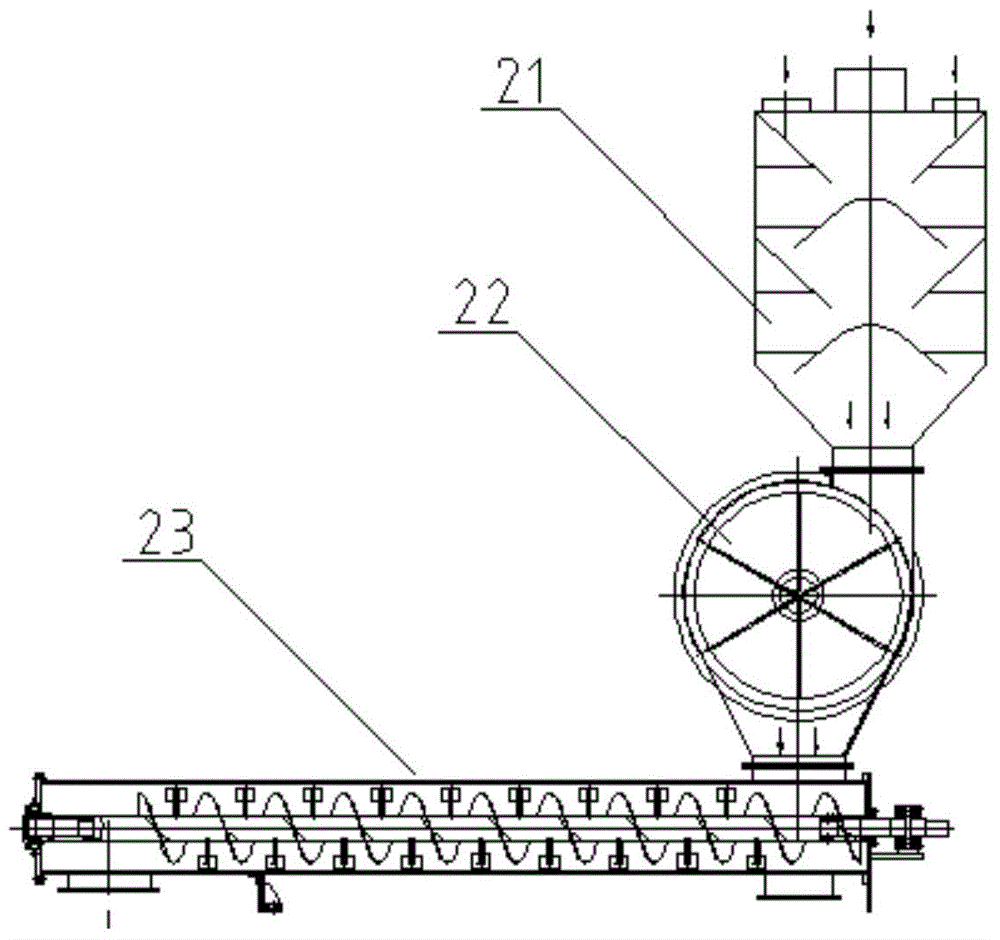

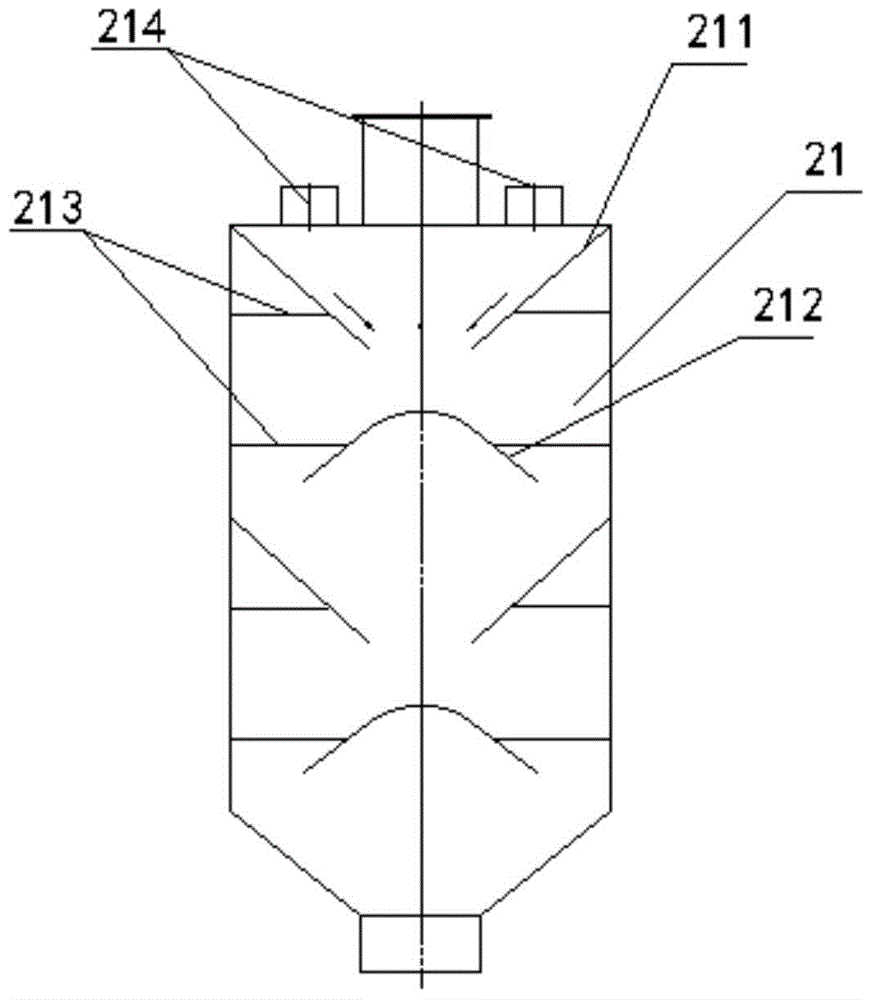

[0033] The dry powder mortar production line that present embodiment provides, as figure 1 As shown, it is mainly composed of a dry sand storage bin 11, a powder bin 14, a dry sand turnover bin 13, a hoist 12, a powder metering mechanism 15, a sand metering mechanism 16, a mixing mixer 22 and a packaging machine 3. The dry sand storage bin 11 is connected with the dry sand turnover bin 13 through a hoist 12 . The powder silo and the dry sand turnover silo are respectively connected to the powder metering mechanism and the sand metering mechanism to form a raw material delivery unit. The output ends of the powder metering mechanism and the sand metering mechanism are connected to the mixer, and the output ends of the mixer are connected to the packaging machine.

[0034] When the continuous dry powder mortar production line is in operation, the sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com