Method for changing position folding line of movable rail seat on winch screw into straight line

A realization method and a technology of a moving rail seat, which are applied in hoisting devices, conveying filamentous materials, thin material processing, etc., can solve the problems of increasing design and manufacturing costs, increasing the demand for space positions, and complex calculation and processing, etc., to achieve The effect of ingenious method, simplified complexity, and simple hardware structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

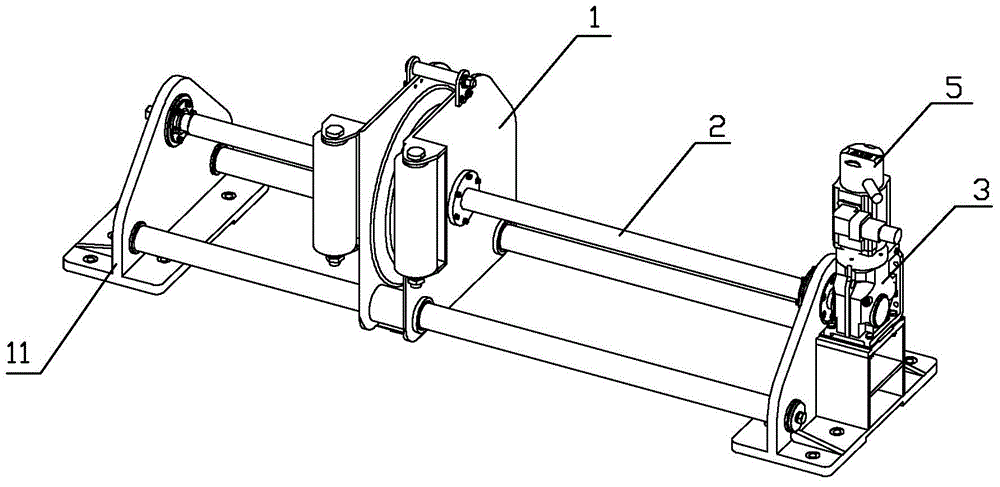

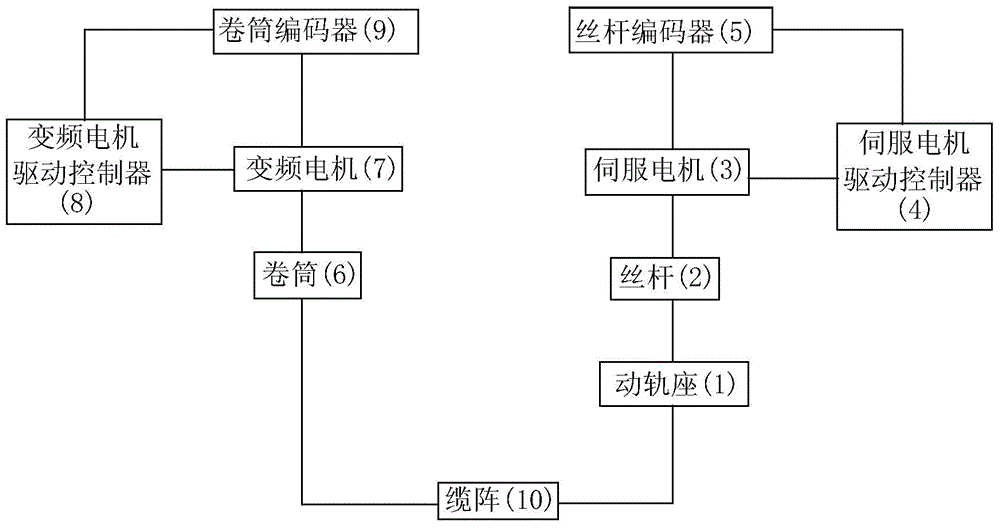

[0022] Embodiment: The method for realizing the folding line of the position of the moving rail seat on the winch screw rod in this embodiment becomes a straight line, which is used in the electrical automatic cable arrangement system of the winch, such as figure 1 As shown, the winch electric automatic cable discharge system includes a moving rail seat 1, a screw 2 and two bases 11, the two bases are installed on the winch, the screw rod 2 is connected between the two bases, and the moving rail seat passes through The screw nut and the bearing are installed on the screw rod. Such as figure 2 As shown, the movement of the moving rail seat 1 is controlled by the screw rod 2, the rotation of the screw rod 2 is controlled by the servo motor 3, the servo motor 3 is controlled by the servo motor drive controller 4, and the screw encoder 5 installed on the servo motor 3 Output signals to the servo motor drive controller 4. The reel 6 is controlled by the frequency conversion moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com