A kind of method for recycling waste polyurethane elastomer to prepare polyurethane insulation material

A polyurethane elastomer and thermal insulation material technology, which is applied in the field of waste polyurethane recycling and preparation of polyurethane thermal insulation materials, can solve the problems of decreased utilization rate, no content related to the recycling of waste polyurethane elastomer, complicated process, etc., so as to achieve clear problem solving and promote promotion Simple effect with application and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

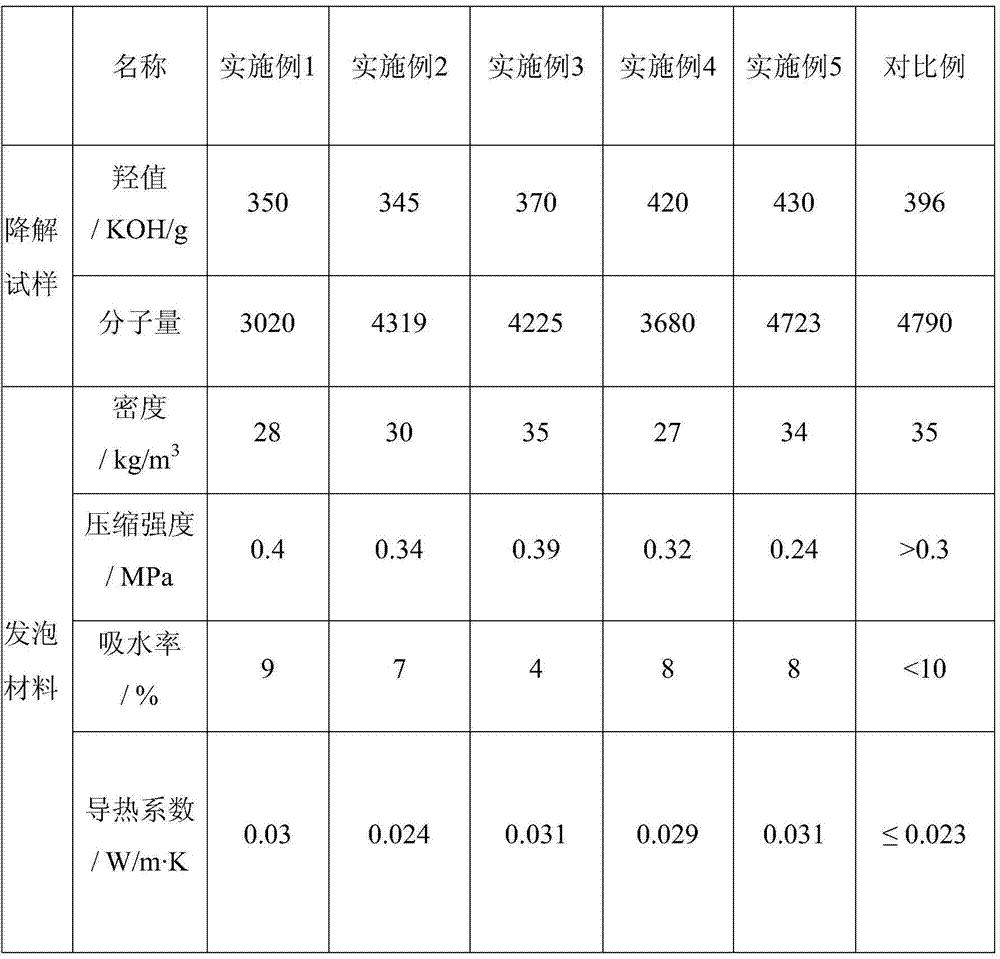

Examples

Embodiment 1

[0025] (1) Mix 10g of waste polyurethane elastomer with 8g of 1,3-propanediol and 1g of triethanolamine, stir at 100°C for 3 hours, and cool to room temperature to obtain the recovered product after degradation;

[0026] (2) 10g of the recovered product after degradation is mixed with 0.1g sucrose, 0.5g glucose, 4.5g HCFC-141b, 0.1g silicone oil L-600, 0.1gPC-41, 0.3g water, stir it evenly and use it as white material, and then mix with 10g PAPI -27 Stir 12S to make it foam, and cool to obtain polyurethane insulation material.

Embodiment 2

[0028] (1) Mix 10g of waste polyurethane elastomer with 7g of 1,3-butanediol and 2g of potassium hydroxide, stir at 150°C for 5 hours, and cool to room temperature to obtain the recovered product after degradation;

[0029] (2) 10g of the recovered product after degradation is mixed with 0.8g of sorbitol, 4.8g of HCFC-141b, 0.2g of silicone oil CGY-5, 0.2g of PC-41, and 0.4g of water as white material, and then stirred with 11g of PAPI-27 11S makes it foam and cools to obtain polyurethane insulation material.

Embodiment 3

[0031] (1) Mix 10g of waste polyurethane elastomer with 8g of 1,2-propanediol and 1g of sodium hydroxide, stir at 170°C for 2.5 hours, and cool to room temperature to obtain the recovered product after degradation;

[0032] (2) 10g of the recovered product after degradation and 0.3g of glucose, 4g of HCFC-141b, 0.5g of silicone oil CGY-5, 0.2g of TMPDA, and 0.1g of water are mixed uniformly and used as white material, and then stirred with 8.5g of PAPI-27 for 16S to make it Foaming and cooling to obtain polyurethane insulation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com