A single-sided reciprocating continuous coating magnetron sputtering winding coating machine

A technology of magnetron sputtering and coating machine, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc. It can solve the problems of inability to sputter three layers of dielectric film continuously, limited number of installations, and many equipments. , to achieve the effect of simplifying the electrical control device and program, facilitating parameter control, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

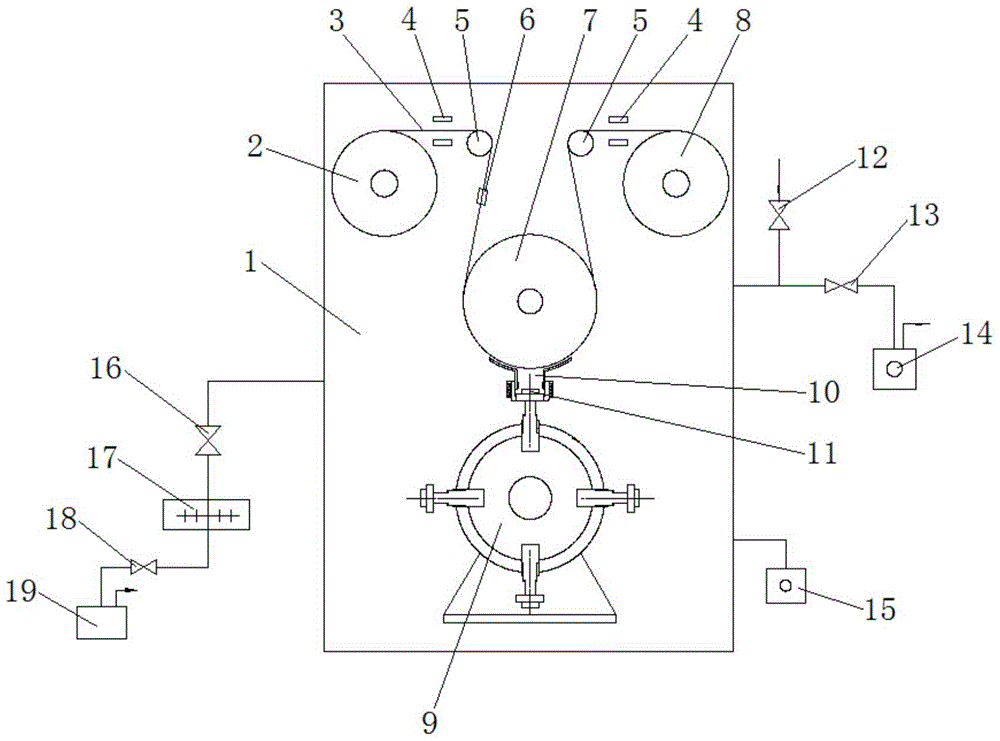

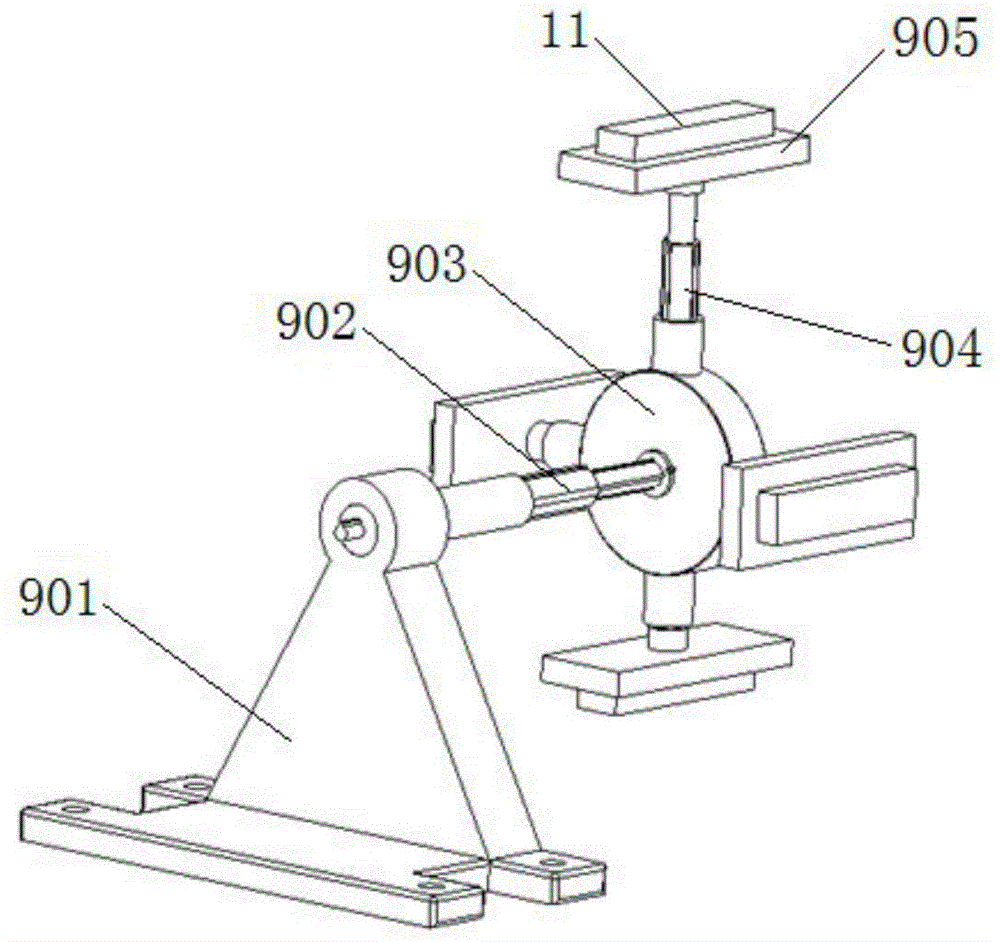

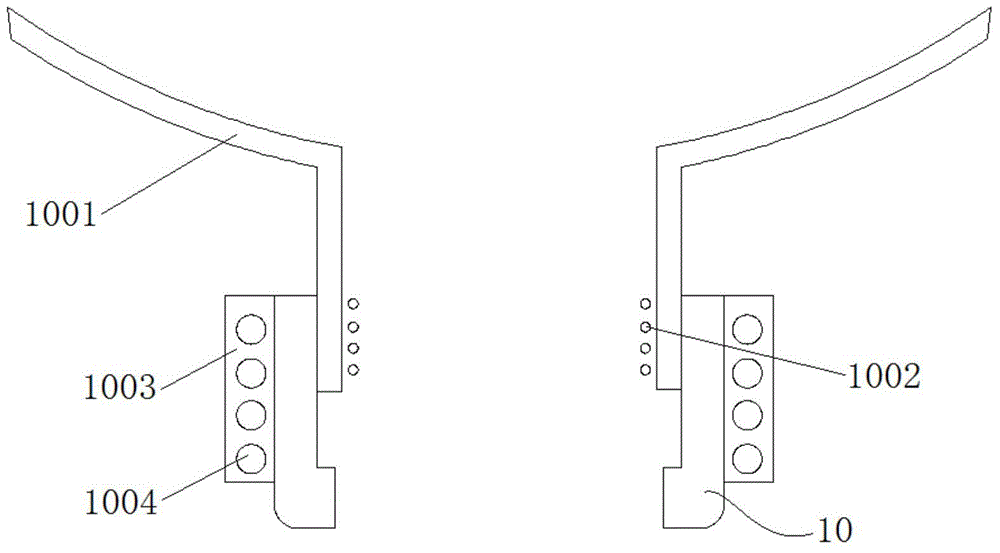

[0033] like figure 1 As shown, a single-sided reciprocating continuous coating magnetron sputtering roll-to-roll coating machine of the present embodiment includes a vacuum chamber 1, an uncoiling mechanism 2 sequentially arranged in the vacuum chamber 1, a cooling roller 7, a winding mechanism 8, an upper and lower The cathode cell 10 with openings on both sides, the return conversion target device 9 and the deviation correction device 4, the unwinding mechanism 2 and the winding mechanism 8 are respectively provided with a set of reversing rollers 5 for changing the direction of the base tape 3, the unwinding mechanism 2 and the winding mechanism 8 Located on both sides of the vacuum chamber 1, the cooling roller 7 is located at a downward position between the unwinding mechanism 2 and the winding mechanism 8, that is, the uncoiling mechanism 2, the winding mechanism 8 and the cooling roller 7 are basically located in an isosceles triangle On the three vertices, it is benefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com