A fast-changing double-sided reciprocating continuous coating magnetron sputtering roll-to-roll coating machine

A magnetron sputtering and coating machine technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of bulky coating machine structure, unfavorable coating high efficiency, limited installation quantity, etc., to achieve Simplify the electrical control device and program, facilitate the control of film layer parameters, and the effect of neat winding edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

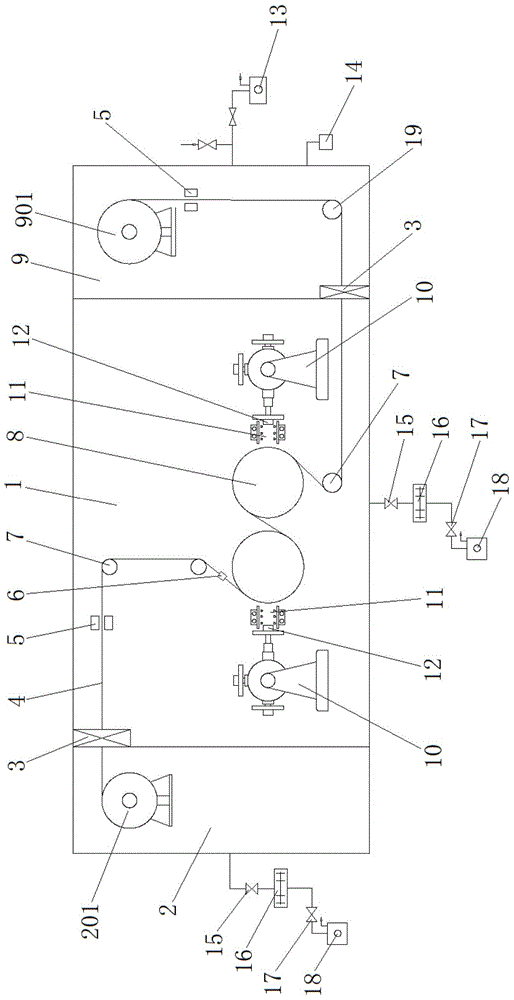

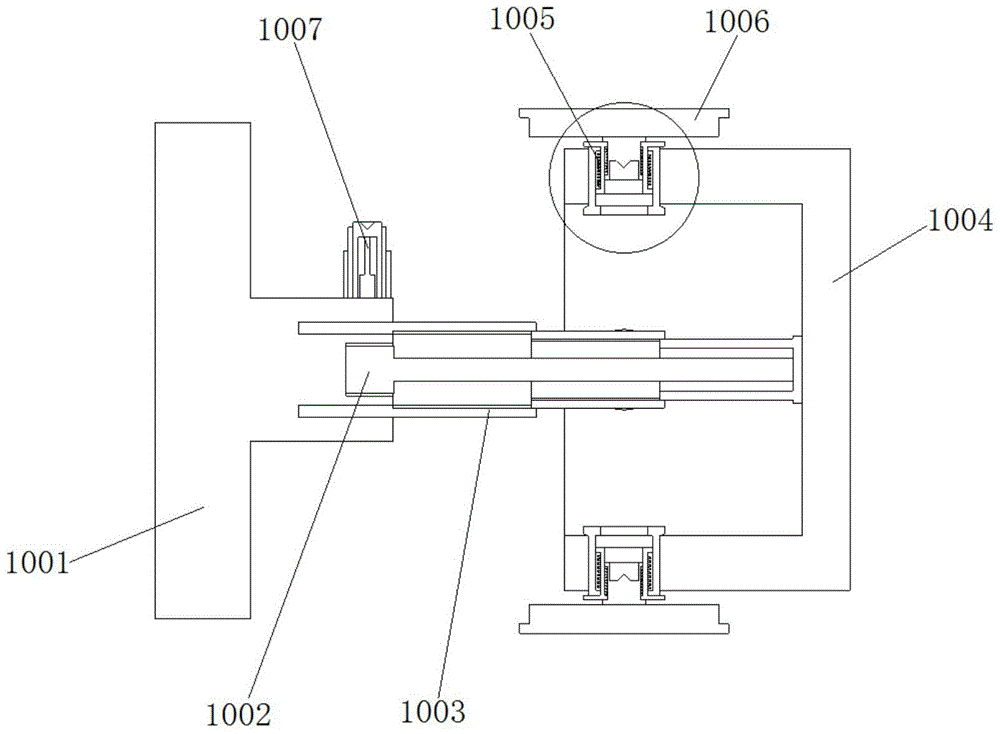

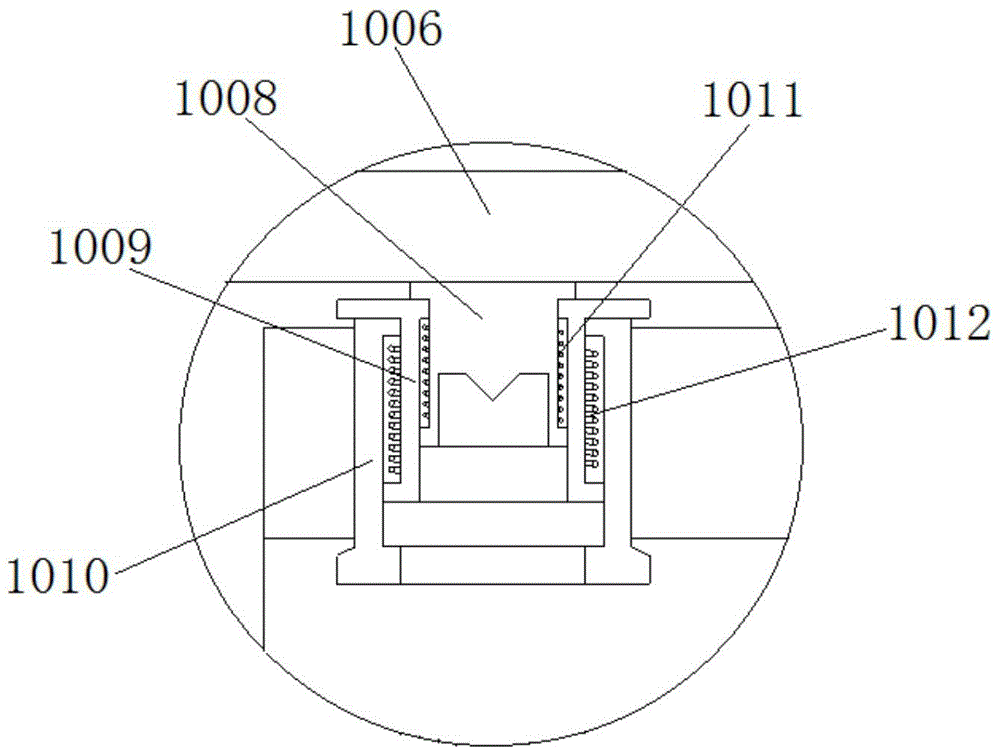

[0036] Such as figure 1 As shown, a kind of rapid target-changing double-sided reciprocating continuous coating magnetron sputtering roll-to-roll coating machine of the present embodiment comprises a vacuum chamber 1, an unwinding chamber 2 and a winding chamber 9 arranged on both sides of the vacuum chamber 1, located in The unwinding mechanism 201 in the unwinding chamber 2, the rewinding mechanism 901 arranged in the rewinding chamber 9, and the two groups of cold rolls 8 arranged in the vacuum chamber 1 also include the return conversion target device 10 and the deviation correcting device 5. A gate valve 3 is provided between the chamber 2 and the vacuum chamber 1, and between the winding chamber 9 and the vacuum chamber 1, to prevent the gas in the unwinding chamber 2 and the winding chamber 9 from entering the vacuum chamber 1, so as to avoid affecting the vacuum The vacuum degree of chamber 1; the base belt 4 between the unwinding mechanism 201 and the winding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com