Method for manufacturing non-woven grid composite non-woven fabric by rotary weft laying method

A non-woven, rotary technology, used in non-woven fabrics, textiles and papermaking, etc., can solve problems such as limit, uneven arrangement of warp and weft yarns, and reduction of product physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

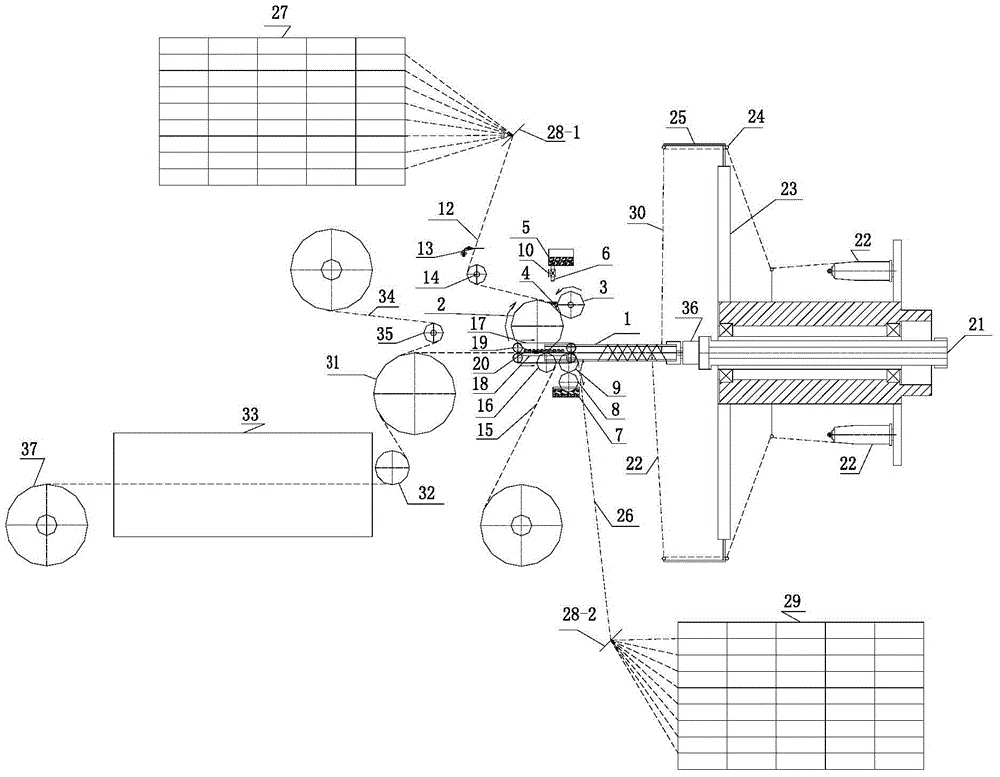

[0097] Example 1 A square nonwoven grid composite nonwoven was produced.

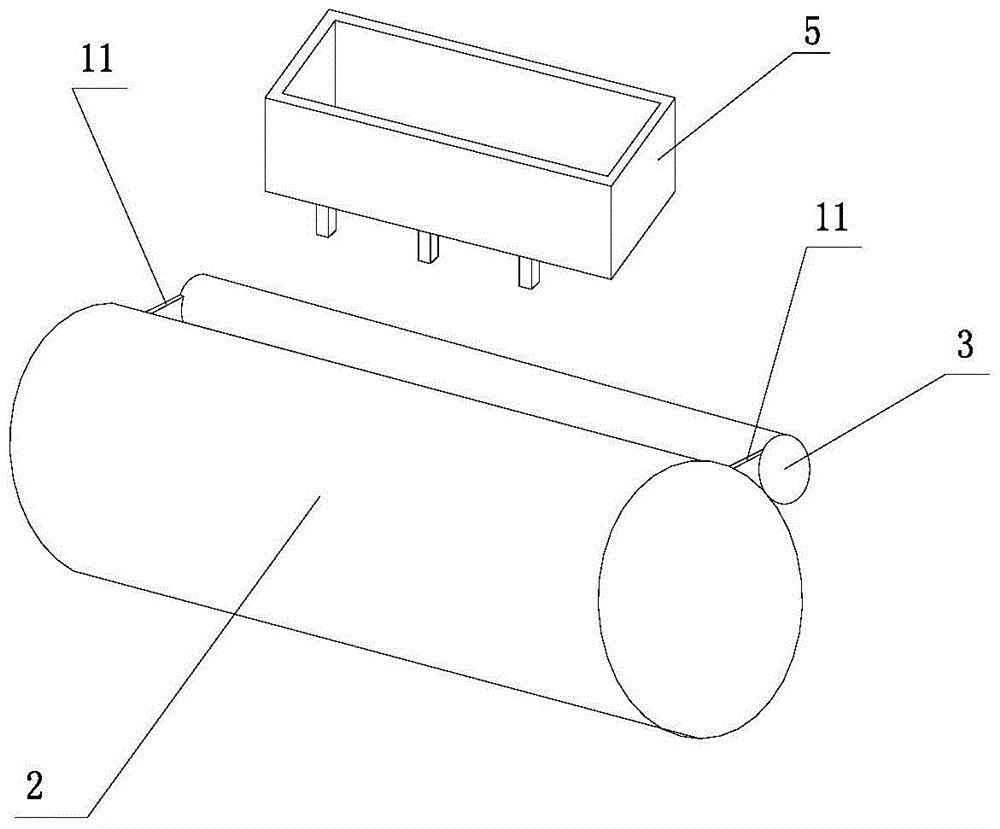

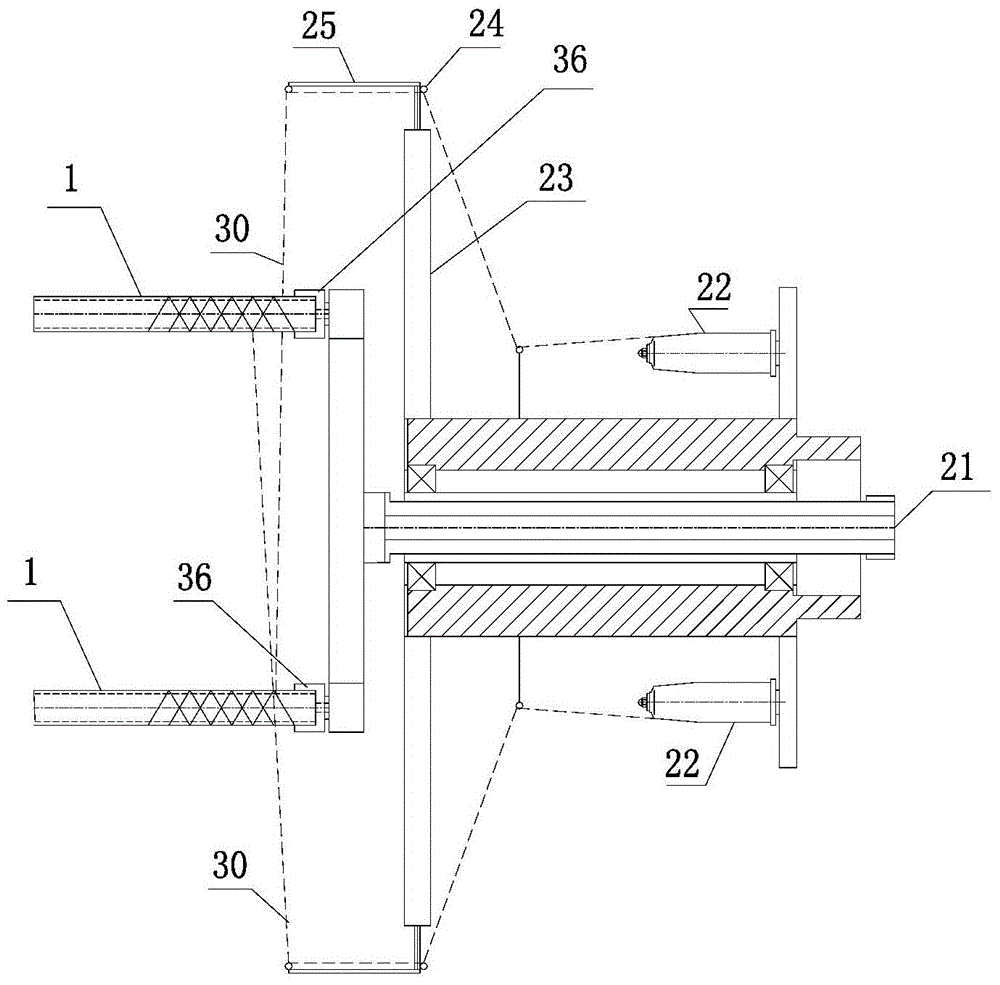

[0098] ① Glass fiber is used as the upper warp yarn (alkali-free 68Tex) and weft yarn (alkali-free 136Tex). The weft yarn 30 of continuous fiber, through the rotation of the large rotary disc 23 of the rotary weft laying machine, the weft yarn is drawn out from the weft yarn head 22 without interruption, and the weft yarn 30 is inserted into the rotating rotary screw through the yarn guide eye 24 and the yarn guide rod 25 1, the weft yarn is evenly wound on the two rotating screws 1; the rotating screw 1 rotates evenly, and the arranged weft yarn moves forward at a uniform speed.

[0099] The structure of the rotary weft laying machine includes a central shaft 21, a large rotating disk 23, a screw rotating head 36, a rotating screw 1, a yarn guide rod 25, a yarn guide eye 24, etc., a large rotating disk 23 is installed on the central shaft 21, and the rotating large Turning disk 23 rotates around centr...

Embodiment 2

[0108] Example 2 A diamond-shaped nonwoven mesh composite nonwoven fabric was produced.

[0109] ① Glass fiber is used as the upper warp yarn (alkali-free 68Tex) and weft yarn (alkali-free 68Tex). The weft yarn of continuous fiber (also can be referred to as oblique rib, because it is not 90 ° angle with warp yarn) 30, by the rotation of large rotating disk 23, weft yarn is drawn out continuously from weft yarn end 22, through guide eyelet 24, The yarn guide rod 25 allows the weft yarn 30 to be embedded in the screw groove of the rotating rotary screw 1, so that the weft yarn is evenly diamond-shaped and wound on the left and right rotary screw 1; the rotary screw 1 rotates evenly, and the arranged weft yarns move forward in translation at a uniform speed.

[0110] The structure of the rotary weft laying machine includes a central shaft 21, a large rotating disk 23, a screw rotating head 36, a rotating screw 1, a yarn guide rod 25, a yarn guide eye 24, etc., a large rotating d...

Embodiment 3

[0119] Example 3 Production of Square Nonwoven Mesh Composite Nonwoven Fabric

[0120] ① Glass fiber is used as the upper warp yarn (alkali-free 68Tex) and weft yarn (alkali-free 68Tex). The weft yarn 30 of continuous fiber, through the rotation of the large rotary disc 23 of the rotary weft laying machine, the weft yarn 30 is drawn out from the weft yarn head 22 without interruption, and the weft yarn is inserted into the rotating rotary screw through the yarn guide eye 24 and the yarn guide rod 25 In the screw groove of 1, the weft yarn is evenly wound on the left and right two rotating screws 1; the rotating screw 1 rotates evenly, and the arranged weft yarn moves forward at a uniform speed.

[0121] The structure of the rotary weft laying machine includes a central shaft 21, a large rotating disk 23, a screw rotating head 36, a rotating screw 1, a yarn guide rod 25, a yarn guide eye 24, etc., a large rotating disk 23 is installed on the central shaft 21, and the rotating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com