Construction method for well point dewatering

A well point dewatering and construction method technology, applied in infrastructure engineering, construction, etc., can solve the problems of easy sedimentation and clogging of filter pipes, unavoidable sedimentation and clogging, unsuccessful dewatering, etc., so as to avoid well point clogging and simple construction operation , is conducive to the effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Construction method for dewatering of deep foundation pit in a project: including

[0026] (1) According to the design drawings of the well point dewatering, measure the line at the construction site to determine the drilling position, groove position and horizontal elevation of the well point;

[0027] (2) Use drilling machinery to drill a well hole that meets the design depth at the determined drilling position;

[0028] (3) Excavation of trenches for laying well point pipelines;

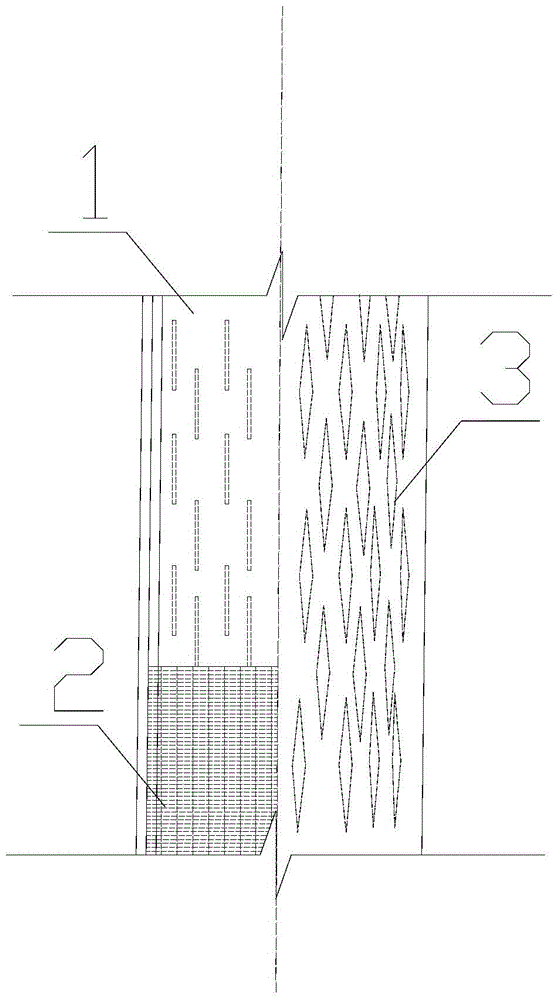

[0029] (4) Pipe laying in the wellbore; specifically, the drill bit of the drilling machine is withdrawn from the wellbore, the wellpoint pipe with the deformable tubular filter assembly at the bottom end is placed in the wellbore, and the bottom end of the wellpoint pipe is fixed to the design depth;

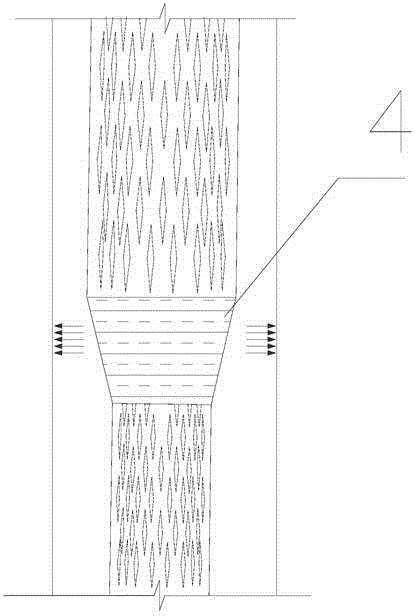

[0030] (5) expand the deformable tubular filter assembly; expand the deformable tubular filter assembly to make it close to the wellbore wall, and play the role of supporting the wellbore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com