Basic structure of a wind turbine

A technology for wind power generators and basic structures, applied in basic structure engineering, construction, etc., can solve the problems of difficult construction and high construction costs, achieve short construction period, convenient construction, and improve compressive resistance and overturning moment resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

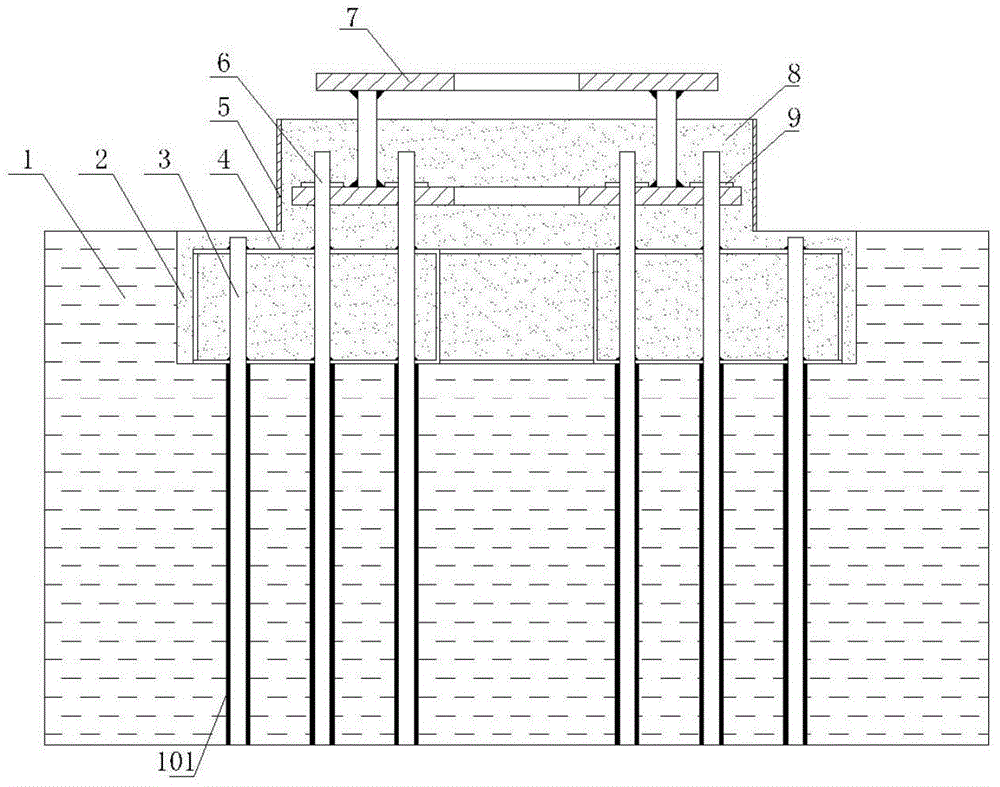

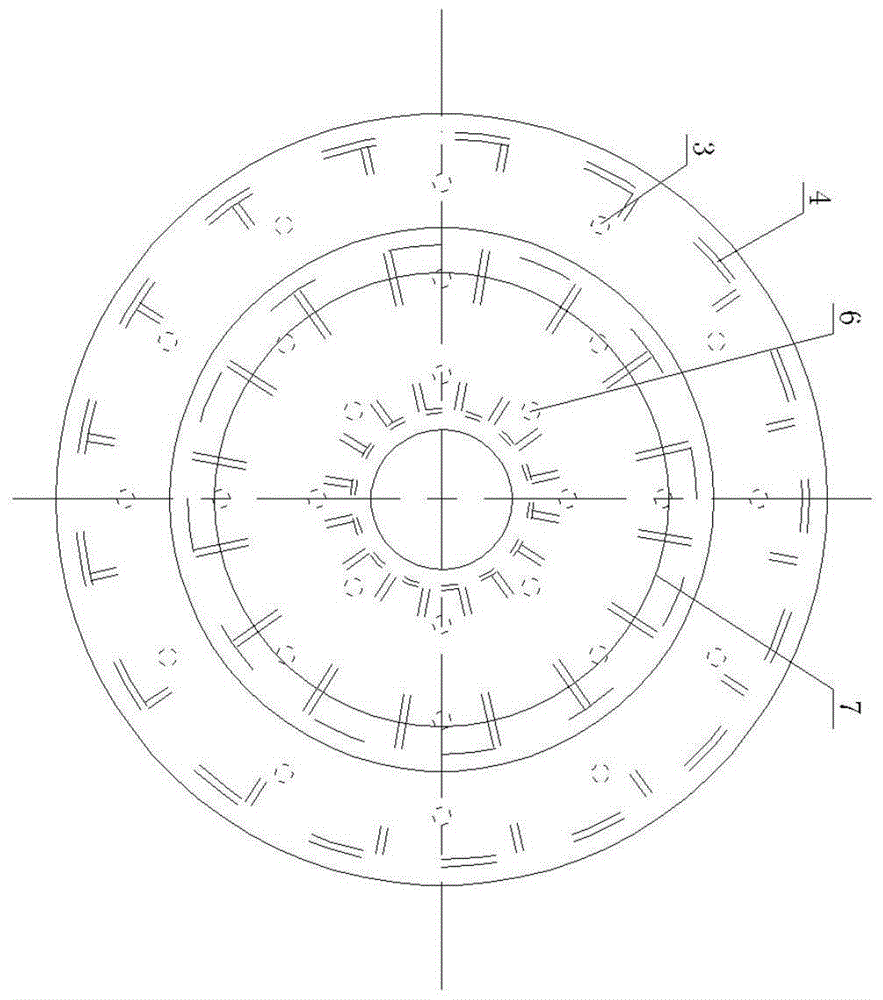

[0027] Such as figure 1 and figure 2 As shown, the basic structure of a wind power generator involved in the present invention includes a cylindrical foundation pit 2, which is excavated on the ground 1, and the depth of the foundation pit 2 is 1-2M. The diameter is determined according to the height and weight of the wind turbine and the diameter of the installation base 7, and at least three concentric and uniformly distributed pipe pile insertion holes 101 are processed on the bottom surface of the foundation pit 2 using a deep hole drilling machine for installing pipe piles; In this embodiment, the pile insertion hole 101 is non-limitingly three circles as an example. Preferably, the depth of the bottom of the pipe pile insertion hole 101 from the bottom of the foundation pit 2 is 6-8M.

[0028] A plurality of machine base pipe piles 6 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com