Steel structure fabricated sunlight room and fabricating method thereof

A steel structure and assembly technology, applied in the direction of sunshade, building components, building structure, etc., can solve the problems of increased construction cost, inconvenient replacement, waste of resources, etc., and achieve simple and convenient installation, improved reliability, and guaranteed sealing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

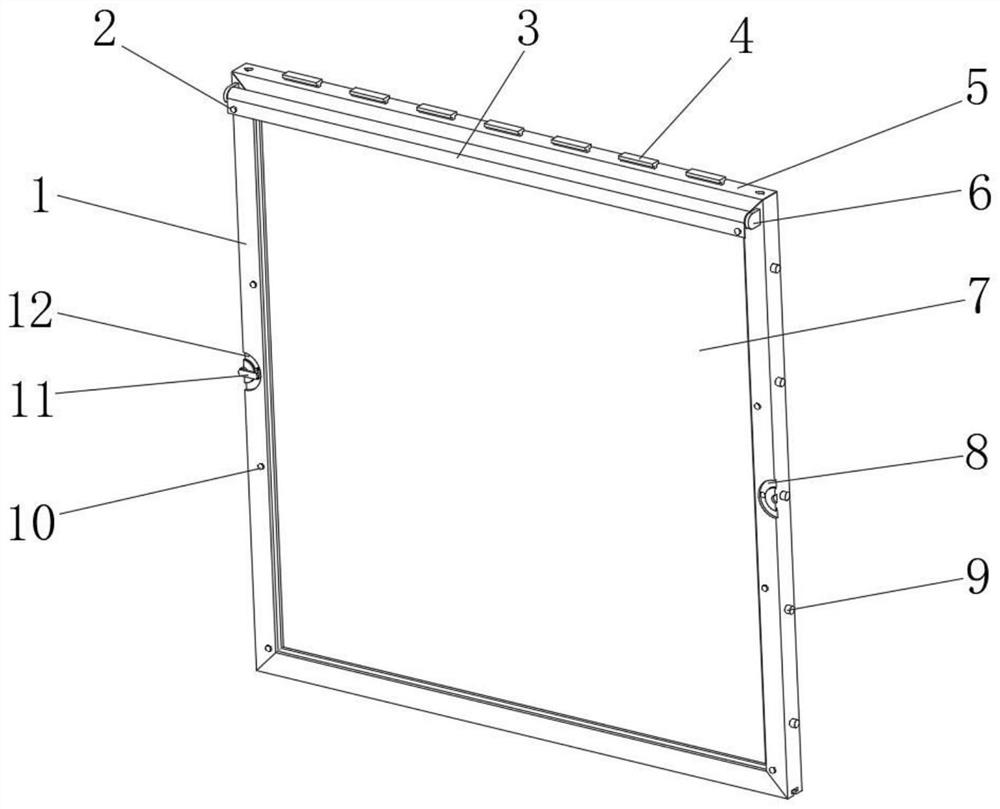

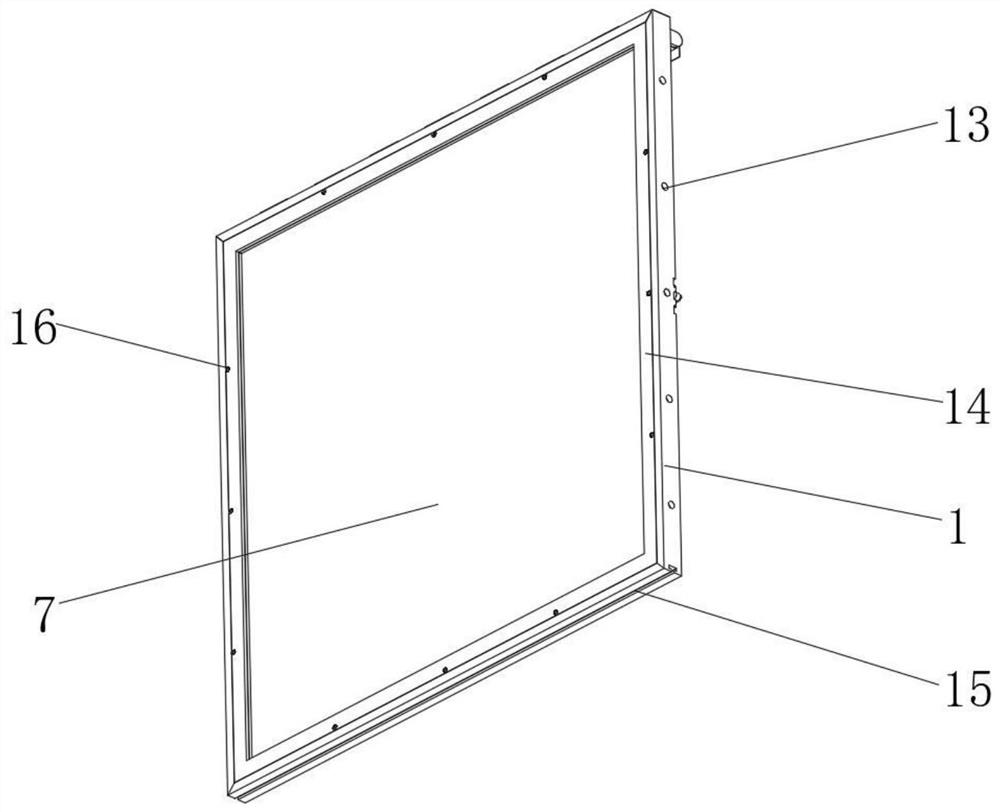

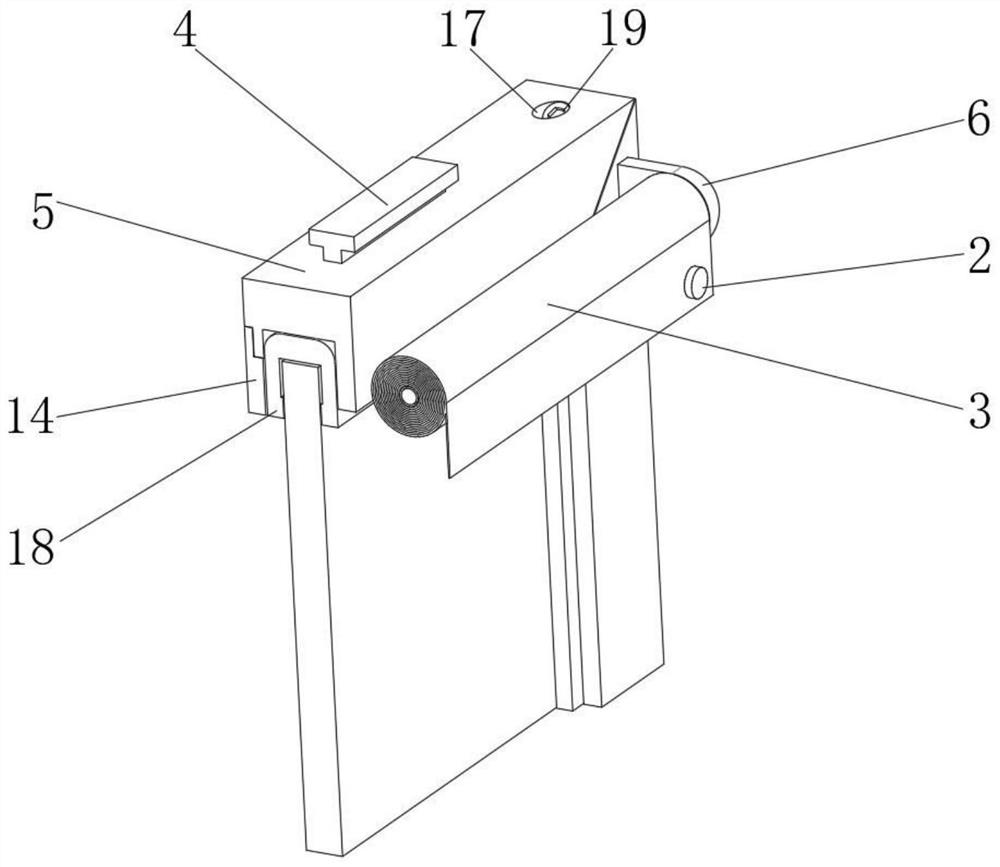

[0046] A kind of steel structure assembly sun house, such as Figure 1-8 As shown, it includes a steel structure glass module, that is, the lighting surface of the conservatory is spliced by multiple steel structure glass modules; the steel structure glass module includes a main frame 1 and a sub-frame 5, and the main frame 1 is in the shape of a square structure, the two ends of the top of the main frame 1 and the top ends of the sub-frame 5 are provided with matching oblique assembly holes 17, and the sub-frame 5 is fixed to the main frame through the oblique assembly holes 17 and the first fastening screws 19. On both ends of the top of the frame 1, rubber sleeves 18 are bonded to the inner walls of the main frame 1 and the sub-frame 5. The rubber sleeves 18 have a U-shaped structure, and the inner walls of the two ends of the rubber sleeve 18 are integrally provided with evenly distributed Connecting film 20, the connecting film 20 has an arc structure, there is a gap of...

Embodiment 2

[0054] A kind of steel structure assembly sun house, such as figure 1 As shown, in order to facilitate the shielding of sunlight according to requirements; this embodiment makes the following improvements on the basis of embodiment 1: the two ends of the main frame 1 are detachably installed with the same mounting frame 6, and the mounting frame 6 is rolled up to cover Roller blind 3: By setting the installation frame 6 and the shielding roller blind 3, it is convenient to roll up or unfold the shielding roller blind 3 according to the demand, thereby shielding the glass plate 7, and improving the practicability.

[0055] In order to facilitate the fixing of the blocking roller blind 3; as figure 1 , image 3 As shown, the blocking roller blind 3 is bonded with a second magnetic block 2 on both sides of one end, and the outer wall of the main frame 1 is embedded with a metal sheet 10 adapted to the second magnetic block 2; by setting The second magnetic block 2 and the metal...

Embodiment 3

[0057] A method for assembling a prefabricated steel structure sun house, comprising the following steps:

[0058] S1: snap the glass plate 7 into the rubber sleeve 18 of the main frame 1;

[0059] S2: Fasten the sub-frame 5 to the top of the glass plate 7, and align it with both ends of the top of the main frame 1;

[0060] S3: Complete the installation of the sub-frame 5 by screwing the first fastening screw 19 into the oblique assembly hole 17;

[0061] S4: Install the side frame 14 on the rib plate 21 of the main frame 1 and the sub-frame 5 through the second fastening screw 16;

[0062] S5: Repeat steps S1 to S4 until the required number of steel structure glass modules are obtained;

[0063] S6: insert a steel structure glass module into the pin hole 13 of another steel structure glass module through the connecting pin 9, and perform horizontal splicing installation;

[0064] S7: insert a steel structure glass module into the slot 15 of another steel structure glass m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com