Processing equipment and processing method for carrying out rust impurity filtering treatment on metallic paint

一种杂质过滤、加工设备的技术,应用在金属漆加工领域,能够解决难以处理污染物、环境不友好、环境污染等问题,达到防止资源浪费、提高筛选效果、提高环境的保护的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

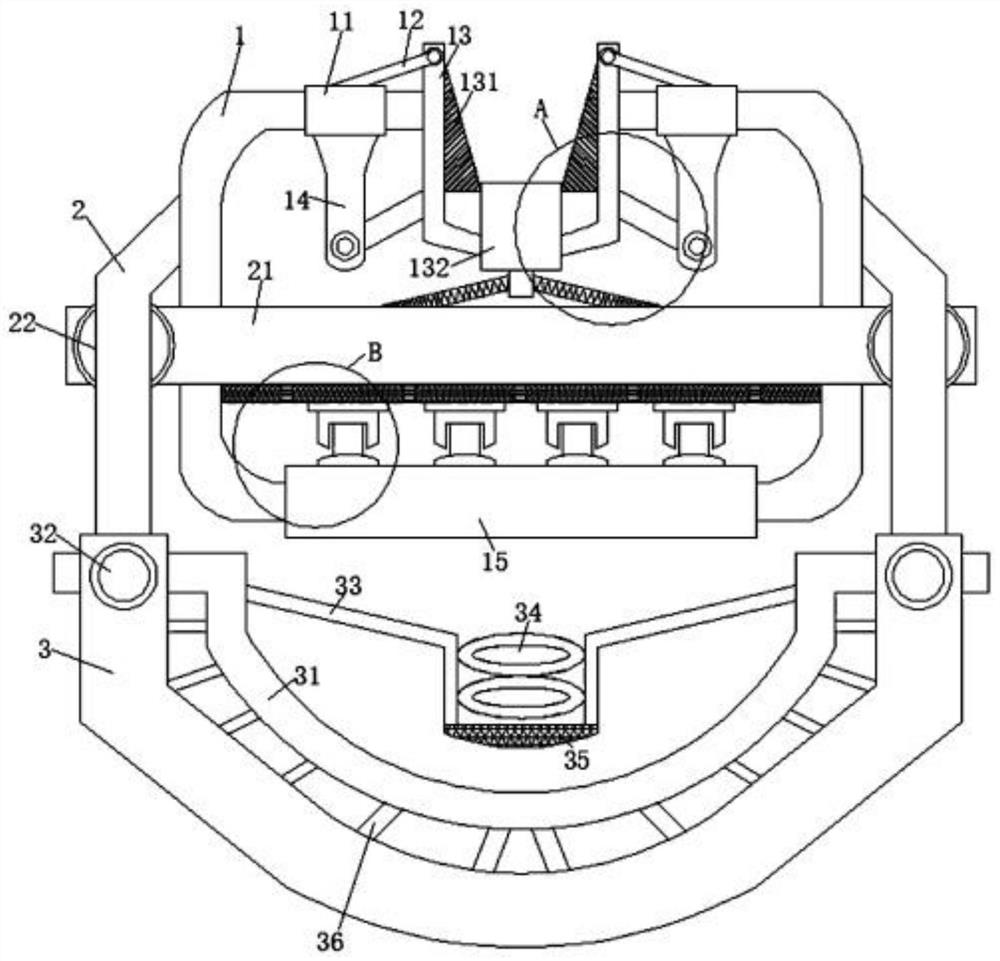

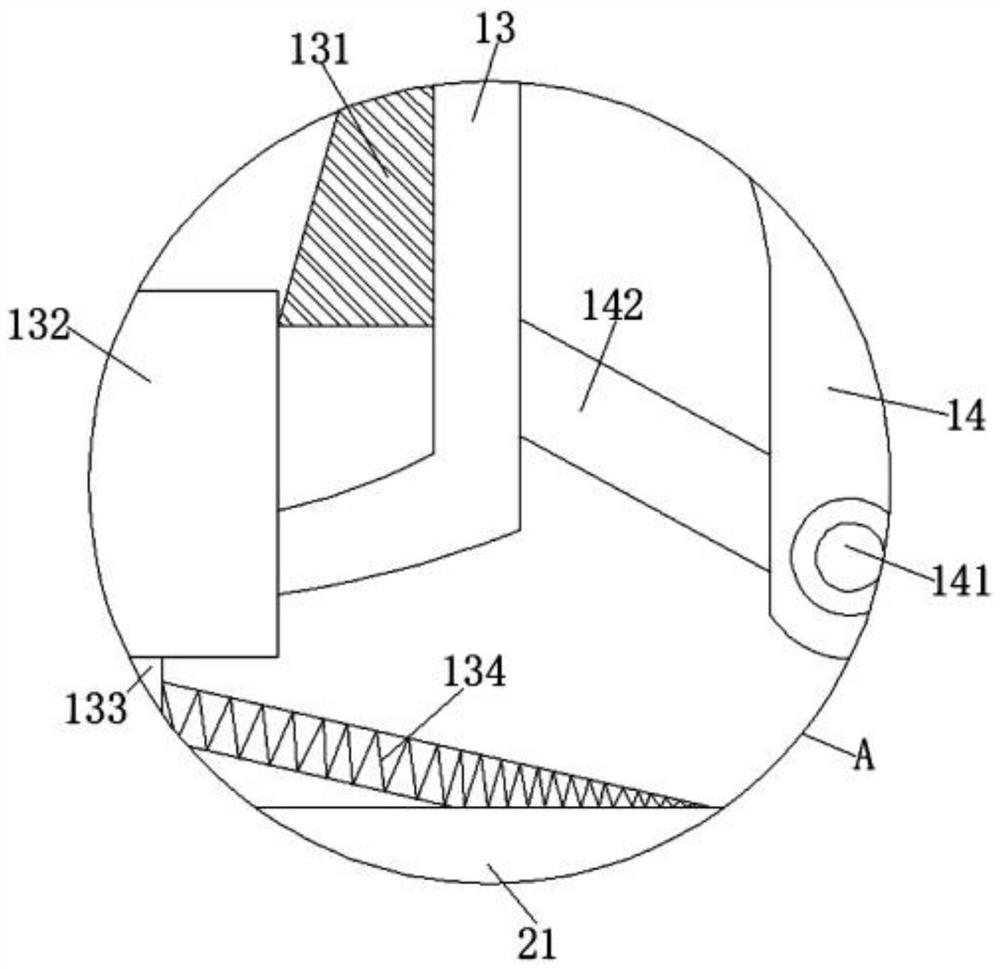

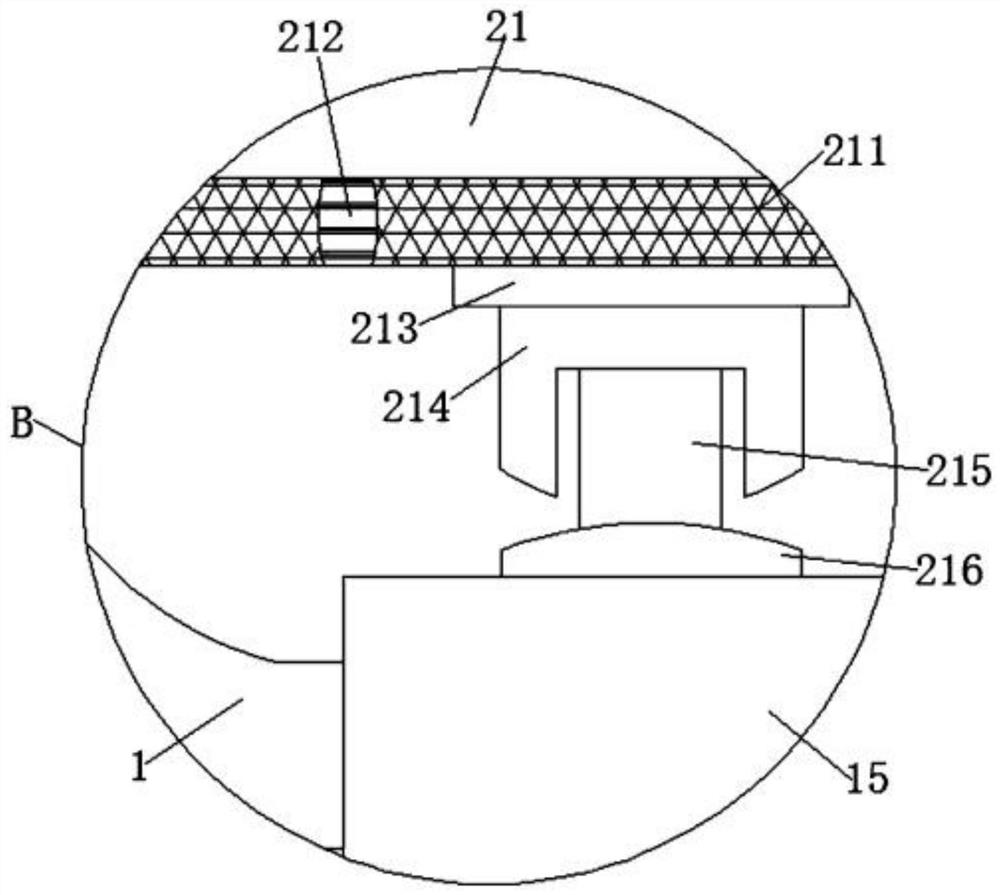

[0036] see Figure 1-6 , a processing device for filtering rust impurities on metal paint, comprising an aggregate collection and treatment device 1, the two sides of the aggregate collection and treatment device 1 located at the top are equipped with positioning support hangers 11, two positioning support hangers The bottom of the seat 11 is welded with a positioning support hanger 14, and the inner cavity of the two positioning support hangers 14 at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com