Solenoid actuator

A technology of solenoids and actuators, applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems such as changes in the response of solenoid actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

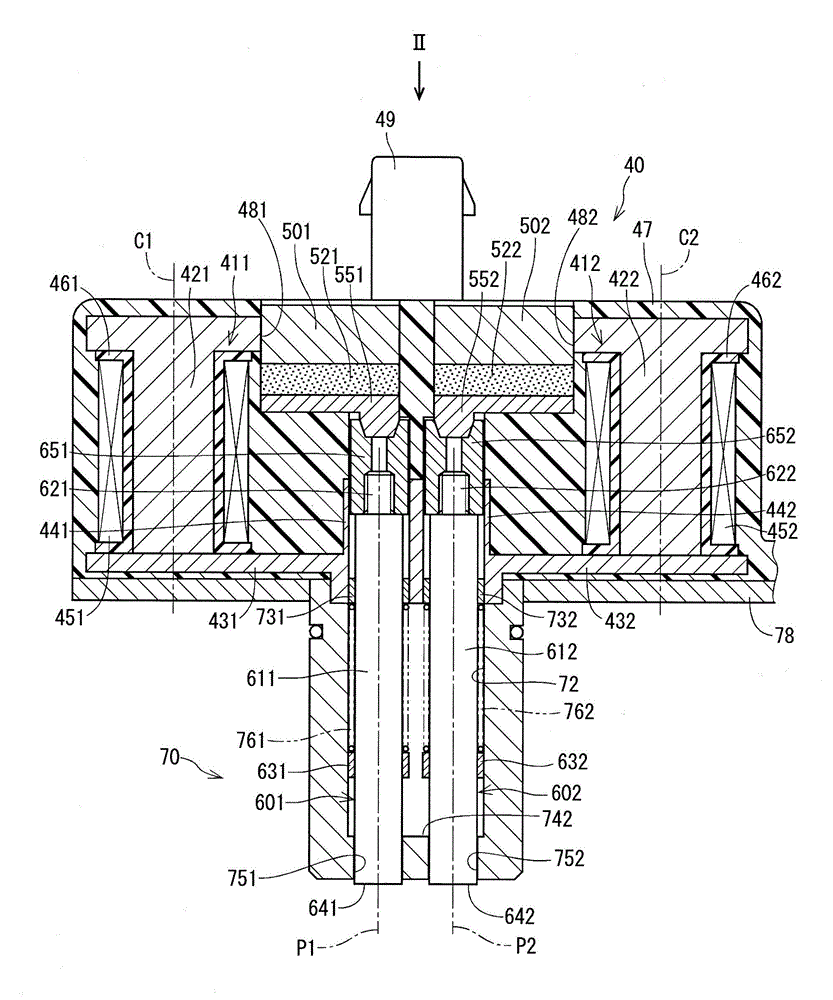

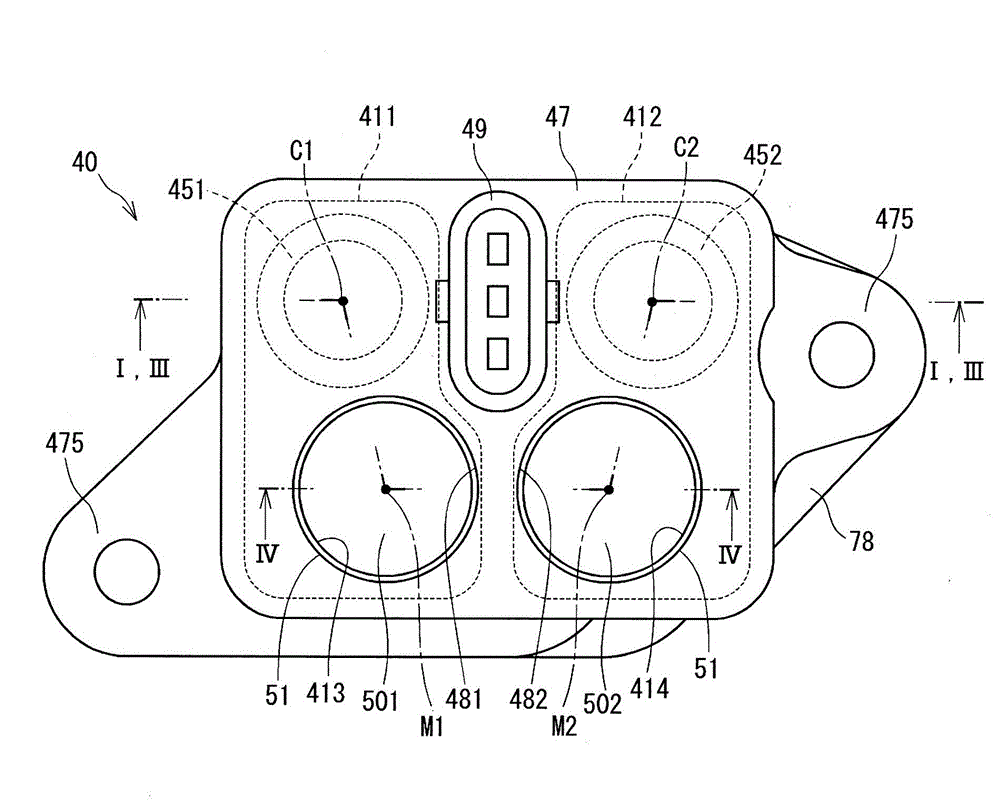

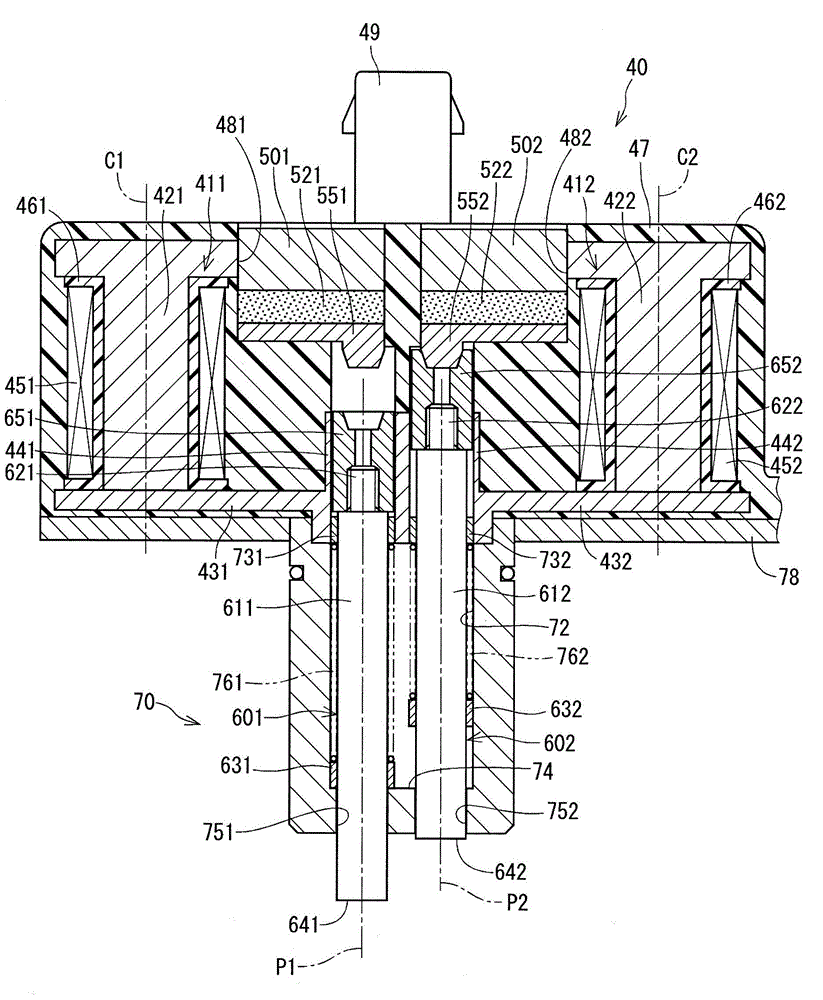

[0030] Embodiments according to the present invention and modifications thereof will be described with reference to the drawings.

[0031] Similar to the solenoid actuator of JP2013-239538A (corresponding to CN103423503A), this embodiment and its modified solenoid actuator are suitable for adjusting the lift of the intake valve or exhaust valve of the internal combustion engine through a cam. In the valve lift adjusting device, the cam is integrally formed with a slider that can rotate integrally with the camshaft.

[0032] The slider of the valve lift adjusting device rotates integrally with the camshaft and is movable in the axial direction relative to the camshaft, and engagement grooves for gradually changing the axial position in response to the rotation angle are formed in the outer peripheral surface of the slider . Based on an instruction received from the control device (control device), the solenoid actuator moves one of the two restricting pins in the forward direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com