Device and method for evaluating temporarily freezing plugging properties of coalbed methane in process of fracturing

A coal seam and air pressure technology, which is applied in the field of freezing temporary plugging performance evaluation devices, can solve the problems of the lack of laboratory research methods on the mechanism of freezing temporary plugging and filtration loss reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

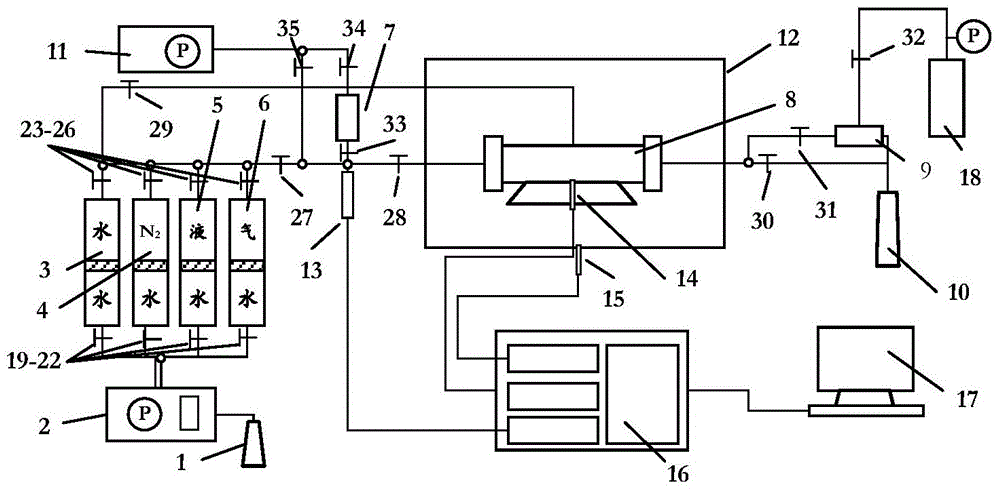

[0018] Attached figure 1 , To further describe the present invention.

[0019] Specific steps are as follows:

[0020] (1) Put the dry coal core into the core holder 8, and connect the equipment and pipelines according to the drawings. Initially, all valves are closed. (Be prepared)

[0021] (2) Open the valves 19, 23, 29, start the booster pump 2, inject distilled water through the intermediate container 3, and apply the confining pressure to the core holder to P s (8MPa), then close valves 19, 23, 29. (Add confining pressure to the core holder)

[0022] (3) Open the valve 34, start the vacuum pump 11, and connect the high-pressure small gas cylinder 7 (V btl =5ml) Vacuum for 1-2 hours, then stop the vacuum pump 11 and close the valve 34. (Evacuate high-pressure small gas cylinders)

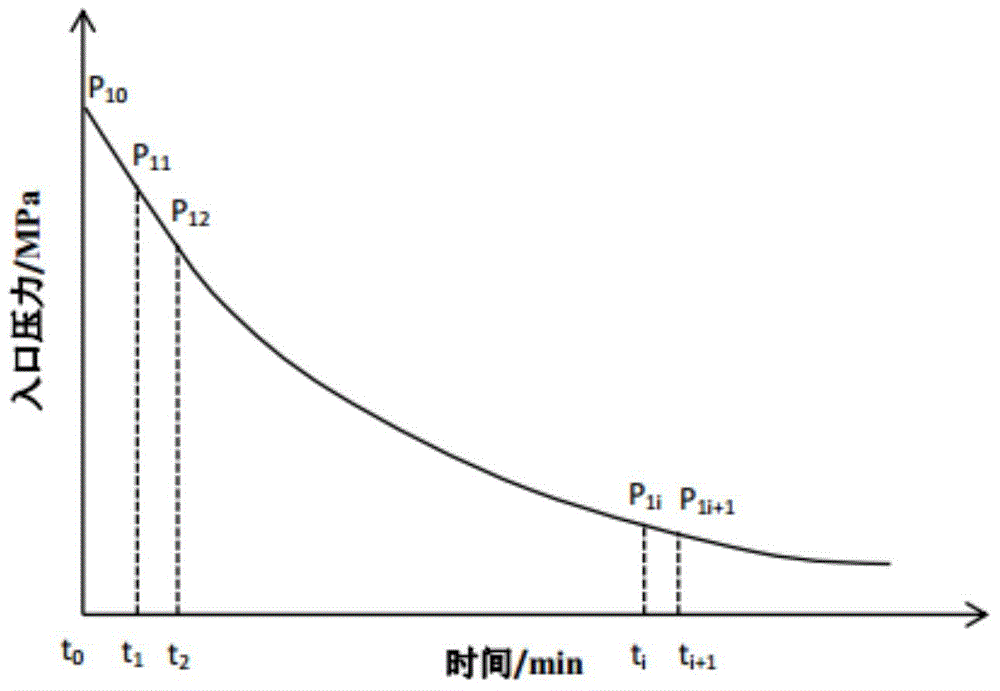

[0023] (4) Open the valves 20, 24, 27, 33, start the booster pump 2, and inject high-pressure N2 into the high-pressure small gas cylinder 7 through the intermediate container 4 to P 1 (6MPa), then cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com