Automatic optical identification system suitable for radio frequency identification label quality checking

A technology for identifying labels and quality inspection, applied in the direction of collaborative devices, instruments, computer parts, etc., can solve problems such as unfavorable adjustment, inability to give offset dimensions, low accuracy of human eyes, etc., to improve yield and output , reducing the effect of human eye accuracy and inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

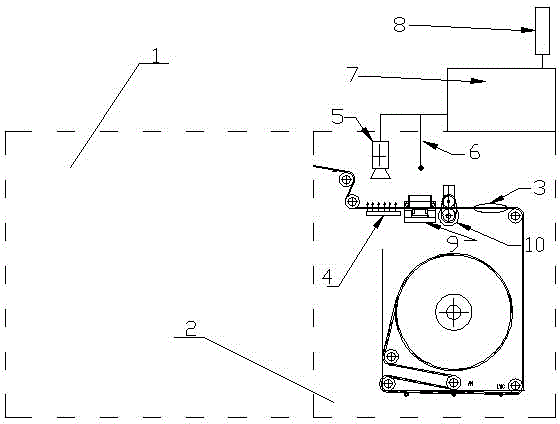

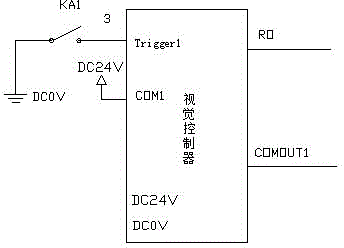

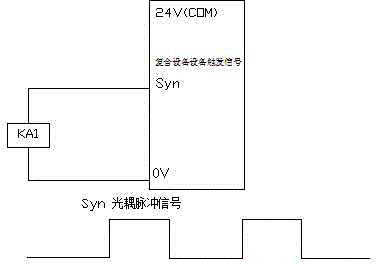

[0016] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention comprises the compound machine that has compound equipment production part 1 and comprises the compound equipment winding part 2 of reader-writer 9, pressing roller 10, and product roll 3 at the front end of reader-writer 9 of compound equipment winding part 2 A plane light source 4 is fixed on the machine platform on one side, and a camera 5 is fixed on the machine platform on the other side corresponding to the product volume 3 of the plane light source 4, and the output of the camera 5 is connected to the AOI controller. When the composite machine is produced, each label will use a reader to detect the radio frequency signal, so each label will give a trigger signal. The present invention is to connect the trigger signal 6 in parallel, and the visual controller in the control box 7 receives the trigger signal. After the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com