Pylon for mounting an engine on the structure of an aircraft

一种飞行器、发动机的技术,应用在动力装置的布置/安装、飞机上动力装置、燃气轮机式动力装置等方向,能够解决声级不利等问题,达到保证安全位置的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

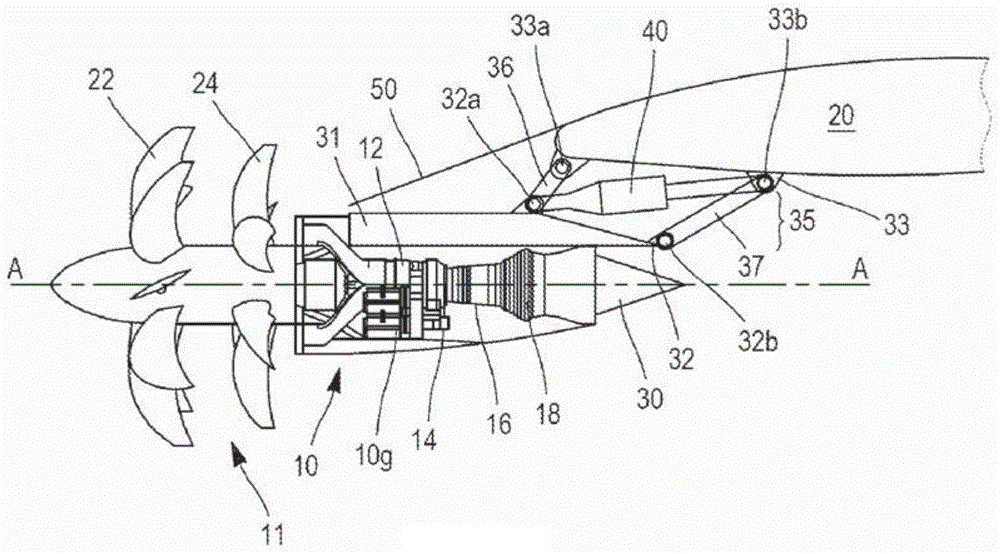

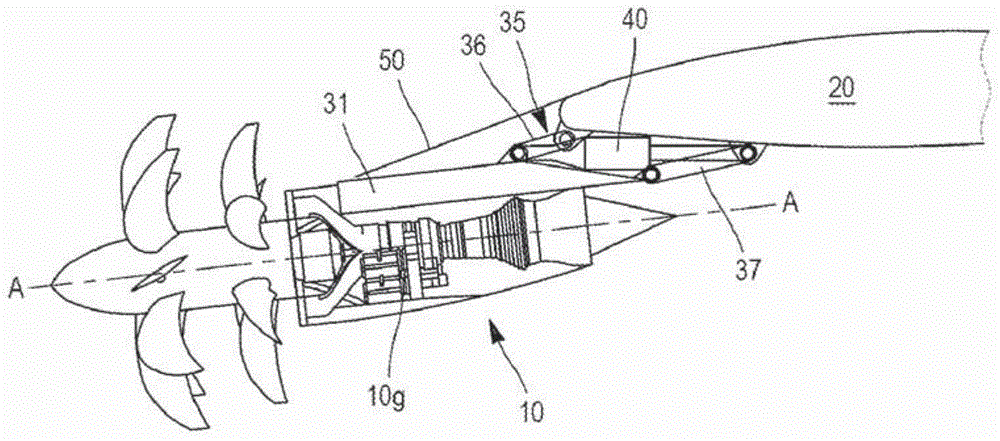

[0021] refer to figure 1 , an "open rotor" turboshaft engine 10 can be seen, this expression designating a pair of ductless propellers. The pair of propellers 11 is arranged upstream of the engine along an extension of the axis of rotation of the engine. The engine comprises, from upstream to downstream in the direction of the air flow in the engine, an air intake communicating with a compressor 12 , an annular combustion chamber 14 and two turbines 16 and 18 . The turbines are each connected to one of the rotors 22, 24 of the propeller it drives.

[0022] Airflow entering compressor 12 is compressed and then mixed with fuel and combusted in combustor 14 . The combustion gases are then injected into the turbine to rotate the rotor of the propeller, which supplies the major part of the thrust produced by the engine. Combustion gases exit the turbine and are expelled through duct 30 in order to increase thrust.

[0023] The propellers 22, 24 are coaxial and arranged in tande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com