Continuous auto-covering pancake machine

A pancake machine and automatic lid opening technology, which is applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problems of unsanitary, heavy workload, etc., to improve production efficiency, improve product efficiency, avoid cumbersomeness and unhygienic sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

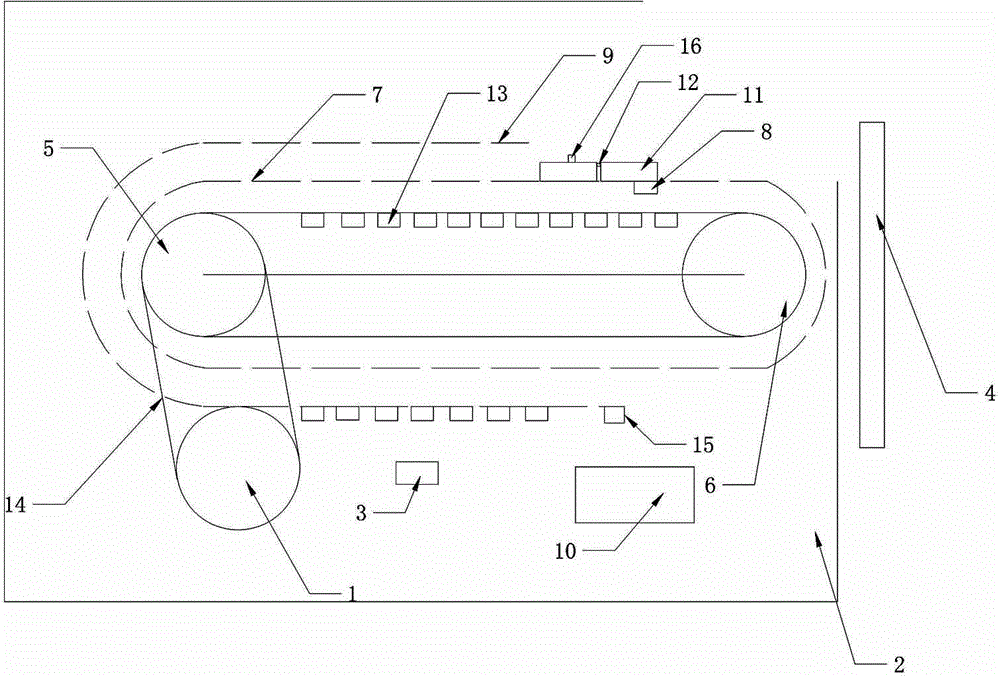

[0021] A continuous automatic capping pancake machine, including a motor 1, a frame 2, an oil supply device 3 and an automatic cake discharge device 4, characterized in that: one side of the frame 2 is equipped with an automatic cake discharge device 4, and the upper end surface of the frame 2 There is a driving wheel 5 and a driven wheel 6, the driving wheel 5 and the driven wheel 6 are connected by a chain plate 7, the starting end of the chain plate 7 is fixedly connected with an automatic capping device 8, and the terminal end of the chain plate 7 is fixedly connected with an automatic cap opening device Device 15, an automatic cake dropping device 10 is provided below the automatic cover opening device 15, and several cake trays 11 are distributed on the outer end surface of the chain plate 7, and the cake trays 11 are connected in groups of two, and the cake trays 11 are connected along the chain plate. 7 are arranged for one week, the upper and lower end surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com