Fastening, indexing and rotating mechanism for central pipe

A technology of indexing rotation and indexing axis, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not being suitable for mass production of five-star feet, low efficiency, and high labor costs, and achieve compact structure , easy operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

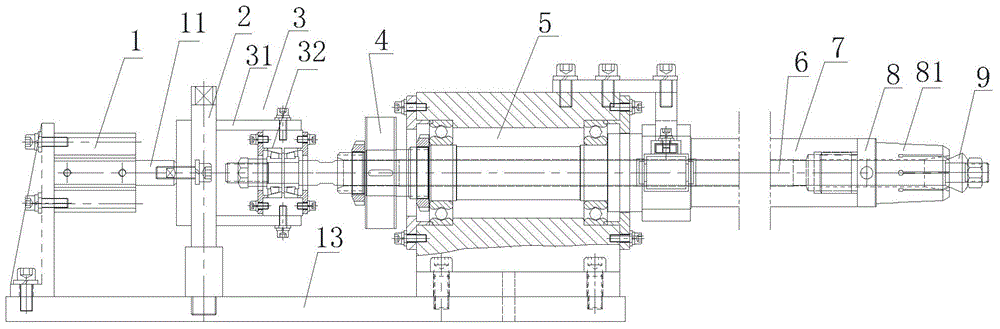

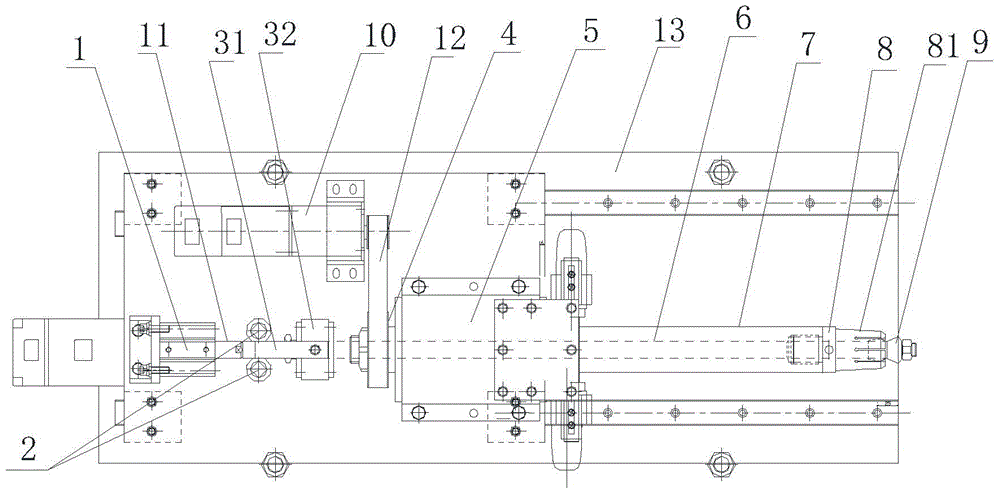

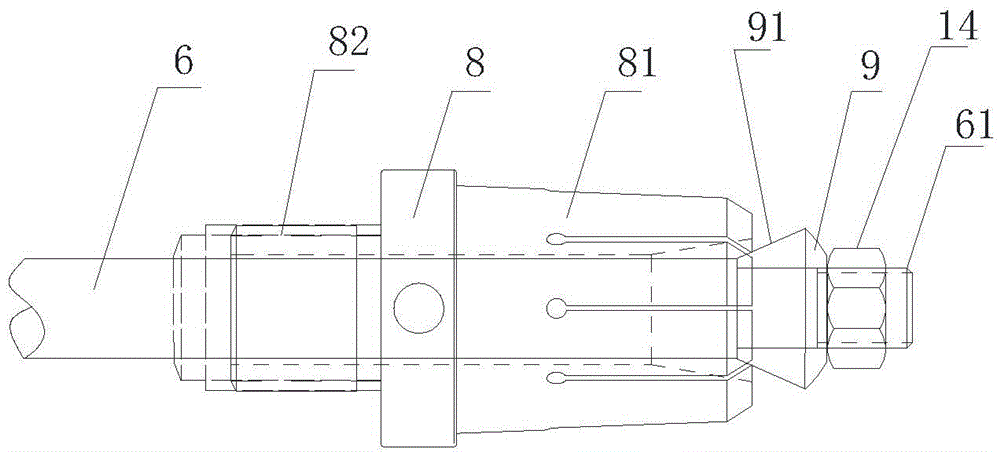

[0016] Embodiment 1: refer to Figure 1~3 . A central tube fastening indexing rotation mechanism, including a base 13, a motor 10 with a brake, an internal expansion rod 6, a cylinder 1, an internal expansion head 8, an indexing shaft 7, a tapered expansion core 9 and an indexing head 5 , cylinder 1, motor 10 with brake and indexing head 5 are relatively mature technologies in the prior art, and will not be described in detail in this patent application. The motor 10 and the cylinder 1 are all fixedly connected to the base 13, the middle part of the indexing shaft 7 is installed in the center mounting hole of the indexing head 5, and the right end of the indexing shaft 7 is connected with the internal expansion head 8. The axial direction of the degree shaft 7 is provided with a central through hole, and the internal expansion rod 6 passes through the central through hole and the internal expansion head 8 and is connected with the conical expansion core 9 located on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com