Interlocking type tool changing mechanical arm device

A manipulator and locking technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of poor self-locking performance, insufficient gripping force, poor precision, etc., to prevent loosening, avoid cutting tools and The effect of swinging the knife and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

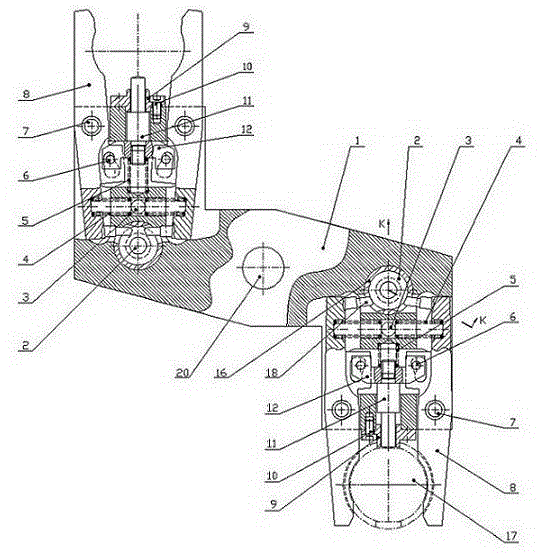

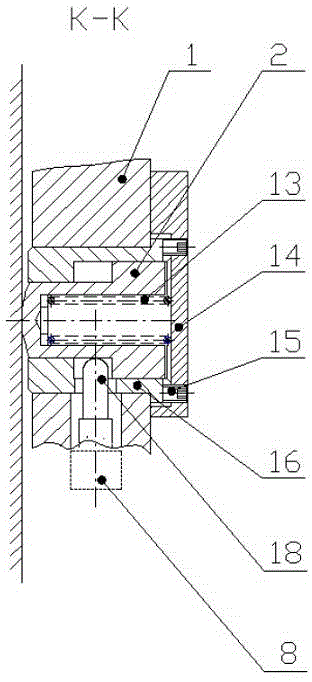

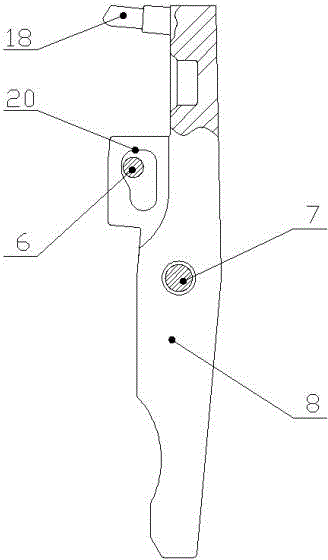

[0021] It includes the main body of the manipulator (1) and the jaws (8). The jaws (8) are arranged in pairs on the main body (1) of the manipulator in the shape of jaws, and are supported by the pivot pin (7) as a movable joint; the whole manipulator device is 180°circumferential symmetry, and fix it to the main transmission shaft (20) through the manipulator main body (1), so that the entire manipulator device can not only rotate along the main transmission shaft (20) circumferential direction, but also along the main transmission shaft ( 20) Axial forward and backward movement, characterized in that: the main body (1) of the manipulator is also equipped with a push rod mechanism, a spring clamping mechanism and a locking mechanism, which are located in the middle, rear and inside of the jaw (8) in sequence. The tail part; the middle part of the jaw (8) is provided with a waist-shaped hole (19) associated with the sliding pin (6) in the ejector mechanism, and the tail is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com