Vehicle functional safety monitoring system

A technology for functional safety and monitoring system, applied in the field of automobile safety, can solve the problems of power system complexity and system cost increase, and achieve the effect of reducing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

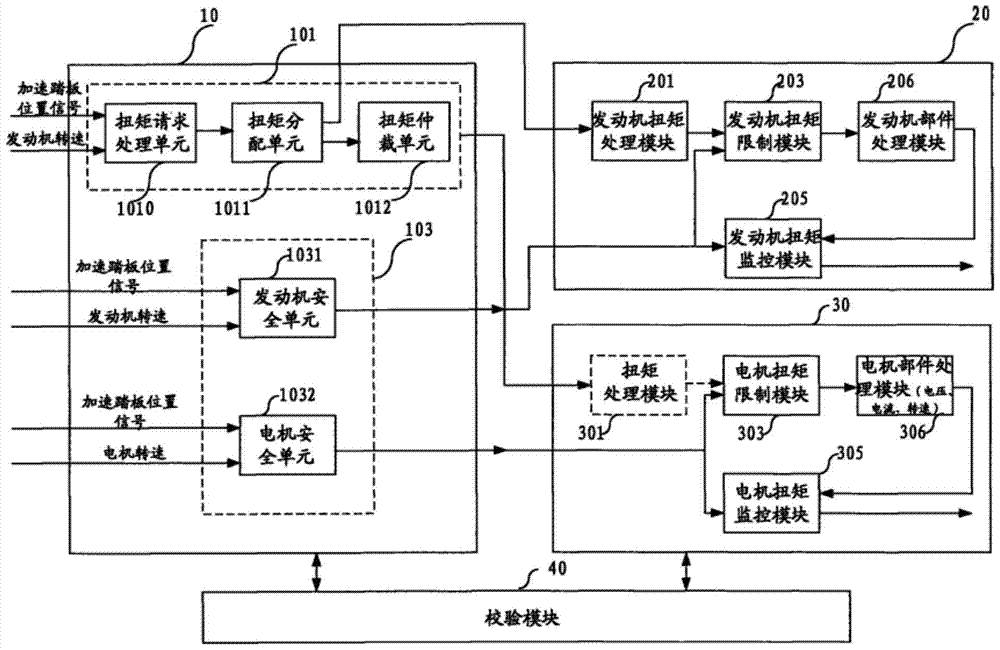

[0037] Vehicle functional safety monitoring system, such as Figure 7 As shown, it includes an acceleration signal source and a main control module 11;

[0038] The acceleration signal source is used to output the instantaneous acceleration of the vehicle to the main control module 11;

[0039] The main control module 11 includes a power control module 111 and a safety acceleration monitoring module 113;

[0040] The power control module 111 is used to calculate the driver's wheel-end demand torque of the vehicle power system, decompose the driver's wheel-end demand torque of the vehicle power system into engine demand torque and motor demand torque, and distribute the engine demand torque to The engine electronic controller distributes the required torque of the motor to the motor controller, and controls the drive chain clutch to work; if it receives the functional safety fault response of the safety acceleration monitoring module 113, it controls to disconnect the drive ch...

Embodiment 2

[0047] Based on the first embodiment, the vehicle functional safety monitoring system further includes a monitoring module 12;

[0048] The monitoring module 12 communicates with the main control module 11 to monitor whether the power control module 111 and the safety acceleration monitoring module 113 are normal. If there is a hardware failure in the module 11, the reset of the main control module 11 is triggered.

[0049] In the vehicle functional safety monitoring system of Embodiment 2, the monitoring module 12 is a hardware monitoring layer, which is mainly responsible for monitoring the main control module 11, preventing logical or temporal failure of the main control module from causing torque calculation errors and causing abnormalities in the vehicle. Expected Accelerated Risk. When the power control module 111 and the safety acceleration monitoring module 113 are not operating normally or there is a hardware failure in the main control module 11, a fault response at...

Embodiment 3

[0051] Based on the vehicle functional safety monitoring system of Embodiment 1, the safety acceleration monitoring module 113 calculates and diagnoses the actual vehicle instantaneous acceleration according to the vehicle instantaneous acceleration information transmitted from the acceleration signal source and the vehicle speed signal;

[0052] If the deviation between the instantaneous acceleration calculated based on the vehicle instantaneous acceleration information transmitted from the acceleration signal source and the instantaneous acceleration calculated based on the vehicle speed signal is within a certain threshold range, it is determined that the acceleration detection information is valid, and the actual instantaneous acceleration of the vehicle under the current working condition is determined. acceleration;

[0053] If the instantaneous acceleration calculated based on the vehicle instantaneous acceleration information transmitted from the acceleration signal sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com