A production device for heterogeneous variable-speed controlled-release fertilizer without secondary blending

A technology of production equipment and different particle speed change, which is applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems of many steps, low production efficiency, complex process, etc., to improve work efficiency, scientific and reasonable process design, and shorten the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

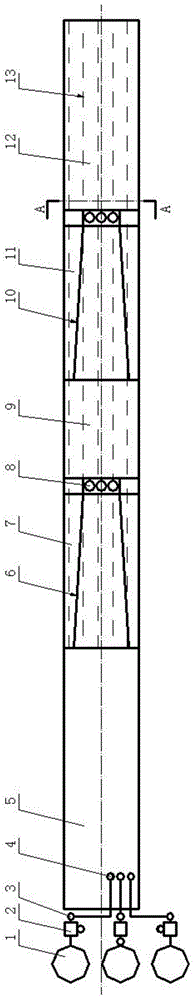

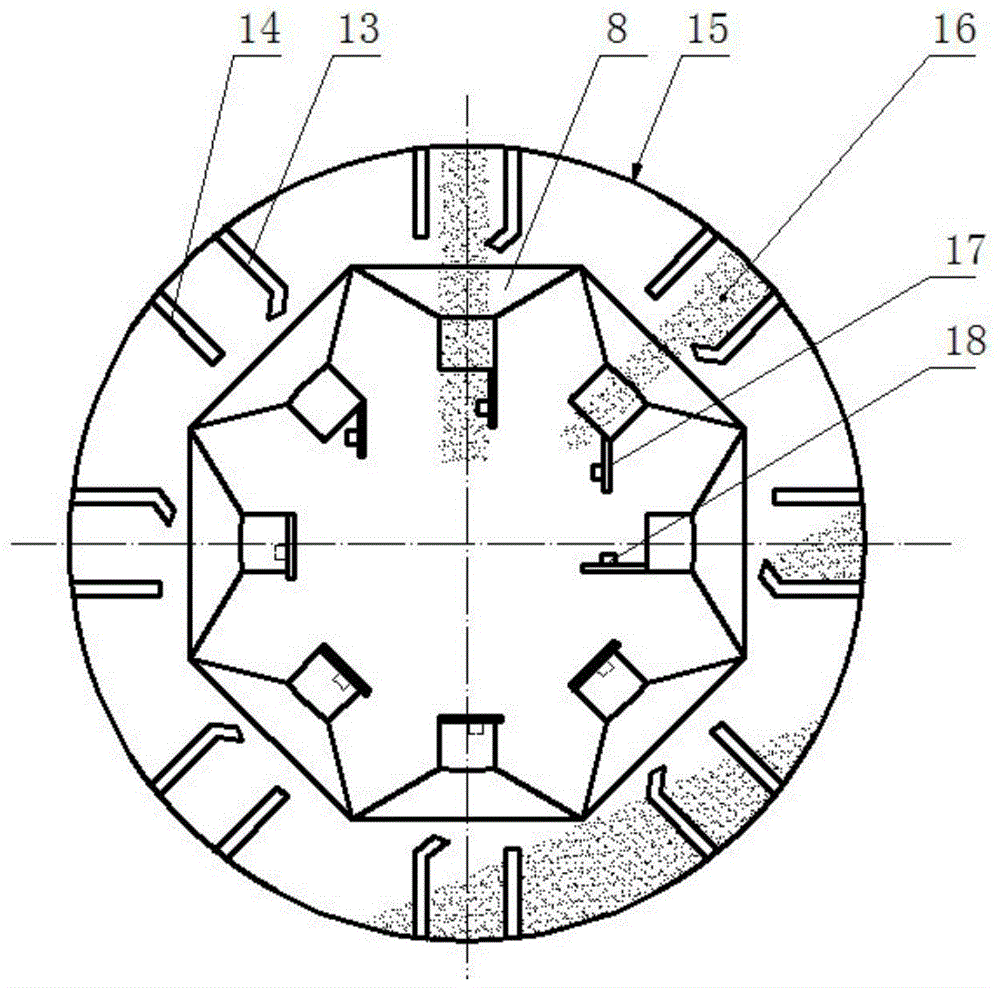

[0019] A production device for heterogeneous variable-speed controlled-release fertilizer without secondary blending, comprising a reactor 1, a metering pump 2, a solenoid valve 3, a nozzle 4, a drum 15, a lifting plate 13 and a blending device. The drum is divided into five sections, from left to right are the coating area 5, the first replacement area 7, the transition area 9, the second replacement area 11 and the synthesis area 12. In the first replacement area, the transition area, the second replacement area and the synthesis area, there are fixed lifting plates at uniform intervals in the radial direction. There are three nozzles installed in the coating area, and each nozzle is respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com