Iron-based sacrificial anode for protecting non-magnetic stainless steel and stainless steel drill collar

A non-magnetic stainless steel, sacrificial anode technology, applied in the field of anti-corrosion, can solve the problems of not forming mature sacrificial anode grades and the performance of sacrificial anodes are quite different, and achieve the effect of reducing short life, easy to fall off, and improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

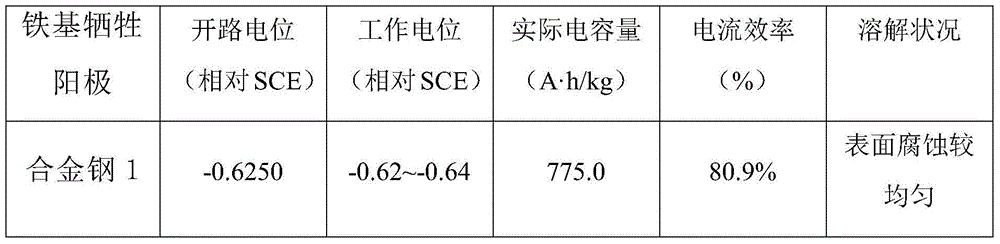

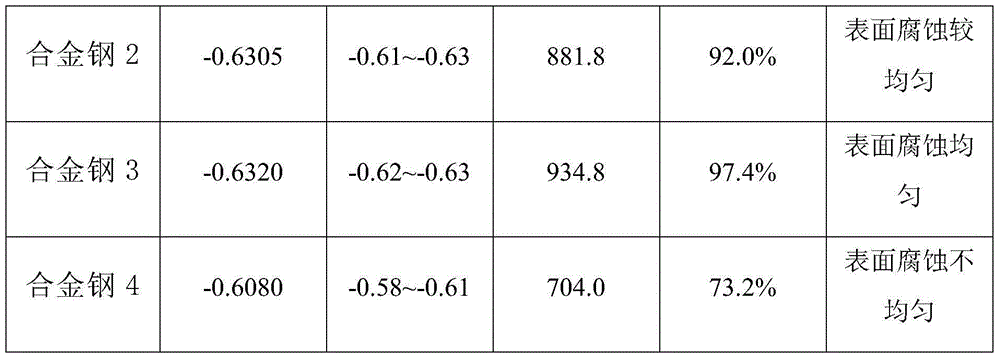

[0029] This implementation takes four iron-based sacrificial anode materials to protect 310S non-magnetic stainless steel as an example. 310S is a commonly used non-magnetic stainless steel with high Cr and Ni content: C is 0.06%, Cr is 25%, and Ni is 20%. , Mn is 2%. Table 2 shows the performance indicators of sacrificial anodes tested by the national standard GB / T 17848-1999 method.

[0030] Table 2 Electrochemical performance of four kinds of iron-based sacrificial anodes when protecting 310S

[0031]

[0032]

[0033] The test results show that the working potential of alloy steel 3 is stable, the current efficiency is the highest, the surface of the sample is corroded uniformly, and the corrosion products are easy to fall off.

[0034] According to the experimental results, the role of alloying elements in the sacrificial anode is summarized: the C content should not be too high, otherwise the conductivity of the alloy will be reduced, and the current efficiency of...

Embodiment 2

[0036] This implementation takes alloy steel 3 as an example to protect F166 non-magnetic stainless steel. F166 is a commonly used non-magnetic stainless steel with high Cr and Mn. The composition is 0.05% of C, 18% of Cr, 18% of Mn, and 0.8%, Mo is 0.8%. The performance of the sacrificial anode tested by the national standard GB / T 17848-1999 method is: open circuit potential -0.6295V, working potential -0.61~-0.62V, actual capacitance 944.4A·h / kg, current efficiency 98.4%. The test results show that when alloy steel 3 protects F166 non-magnetic stainless steel, the working potential is stable, the current efficiency is high, the surface of the sample is corroded uniformly, the corrosion products are easy to fall off, and it has excellent sacrificial anode performance.

Embodiment 3

[0038]In this implementation, alloy steel 3 is used to protect P550 non-magnetic stainless steel as an example. P550 is also a commonly used non-magnetic stainless steel with high Cr and Mn. The composition is 0.04% of C, 20% of Cr, 18% of Mn, and 3.0%, Mo is 3.0%. Using the national standard GB / T 17848-1999 method to test the performance of the sacrificial anode is: open circuit potential -0.6315V, working potential -0.62~-0.63V, actual capacitance 913.0%, current efficiency 95.1%. The test results show that when alloy steel 3 protects P550 non-magnetic stainless steel, the working potential is stable, the current efficiency is high, the surface of the sample is corroded uniformly, the corrosion products are easy to fall off, and it also has excellent sacrificial anode performance.

[0039] The 3 components of alloy steel selected here can be extended to a more suitable composition range according to several test times: C is 0.15-0.20wt%, Mn is 0.5-0.85wt%, Cr is 0.8-1.25wt%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com