Acidic electroplating zinc-nickel alloy electrolyte, preparation method and electroplating method

A technology of zinc-nickel alloy and acid electroplating, which is applied in the direction of jewelry, etc., can solve the problems that it is difficult to fundamentally guarantee the bonding force, quality assurance, acid zinc-nickel electroplating quality, and product quality cannot be fundamentally guaranteed. Effects of complexity, short preparation time, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

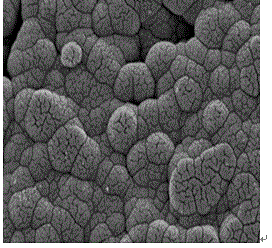

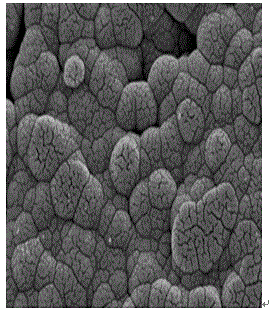

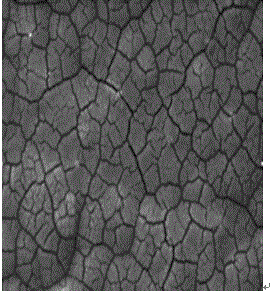

Image

Examples

Embodiment 1

[0042] A kind of acid electroplating zinc-nickel alloy electrolyte composition and content are as follows:

[0043] Basic electrolyte:

[0044] components unit select value Zinc ions g / L 27 Nickel ions g / L 23 total chloride ion g / L 150 boric acid g / L 25 temperature ℃ 28 pH 4.8 Cathode current density A / dm2 1 Anode current density A / dm2 0.5

[0045] additive

[0046]

[0047] To prepare 100L of the above electrolyte composition, the specific steps are as follows:

[0048] (1) Add 60L of deionized water with a total volume of the bath to the plating tank, heat it to 60°C, then add 3 kg of boric acid and 6.3 kg of zinc chloride, and stir to dissolve;

[0049] (2) Add 10 kg of nickel chloride and stir to dissolve;

[0050] (3) Add 11.25 kg of potassium chloride, which is half of the mass ratio, stir to dissolve, and lower the temperature to 30°C;

[0051] (4) After stirring until...

Embodiment 2

[0066] Basic electrolyte:

[0067] components unit select value Zinc ions g / L 37 Nickel ions g / L 31 total chloride ion g / L 220 boric acid g / L 35 temperature ℃ 35 pH 5.4 Cathode current density A / dm2 3 Anode current density A / dm2 1

[0068] additive

[0069]

[0070] On the basis of Example 1, the preparation method and electroplating method of Example 1 were used for testing. The hardness, corrosion resistance, wear resistance, high temperature oxidation resistance, compactness and comprehensive performance were high. The electroplating method and electrolytic The liquid has the advantages of no post-plating treatment process, cost saving, high efficiency and quick operation, and convenient operation, which is far superior to the traditional alkaline zinc-nickel electroplating.

Embodiment 3

[0072] Basic electrolyte:

[0073] components unit select value Zinc ions g / L 30 Nickel ions g / L 25 total chloride ion g / L 180 boric acid g / L 30 temperature ℃ 32 pH 5.2 Cathode current density A / dm2 2 Anode current density A / dm2 0.6

[0074] additive

[0075] code name effect Chemical Name select value Bri+B Primer Benzylideneacetone 2ml / L A walking agent Nonylphenol polyoxyethylene ether 27ml / L MV complexing agent Disodium edetate 40ml / L

[0076] On the basis of Example 1, the preparation method and electroplating method of Example 1 were used for testing. The dosages of the basic electrolyte and additives in this example are optimal values. Too much will easily increase the brittleness of the coating and affect the bonding force.

[0077] The performance parameter test of the electroplating layer of the above embodiment is as follows: (the av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Anode current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com