Turning type electrode group fabric atmosphere plasma treatment mechanism and two-side treatment mechanism

A flip-up, textile technology, used in textiles and papermaking, fiber processing, physical processing, etc., can solve problems such as energy consumption, high water consumption, and the use of large sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

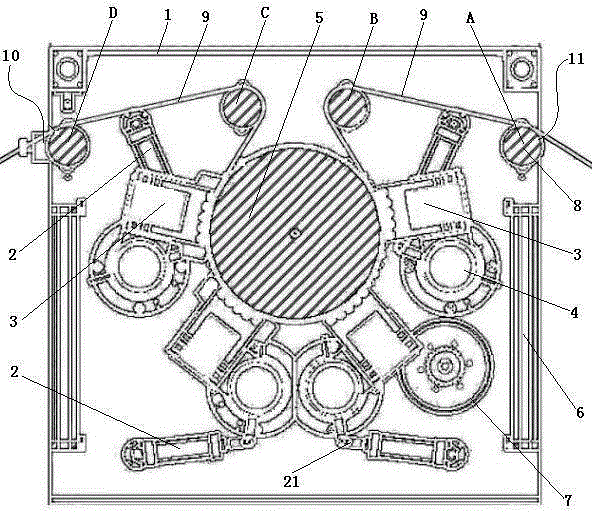

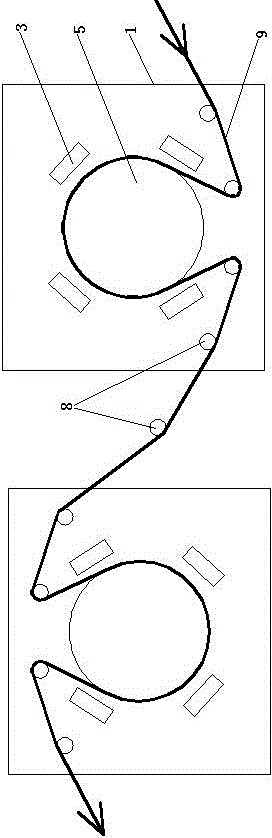

[0020] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0021] like figure 1 As shown in the figure, an atmospheric plasma treatment mechanism for textiles with an inverted electrode group includes: a chassis 1, a water-cooled discharge roller 5 disposed in the chassis 1, and at least one group of inverted ceramic electrode groups 3 disposed on the outer periphery of the water-cooled discharge roller 5 , the textile 9 is guided by the guide roller 8 and passes through the cloth inlet 11, the water-cooled discharge roller 5 and the cloth outlet 10 in turn. The reversible ceramic electrode group 3 is connected with a cylinder, and the reversible ceramic electrode group 3 can be pressed and held by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com