Overall reinforcement binding and hoisting construction method and construction device adopting upstroke movable scaffolding

A technology for moving formwork and construction devices, which is used in the erection/assembly of bridges, bridges, buildings, etc., and can solve the problems of high requirements for gantry cranes, the inability of gantry cranes to meet construction requirements, and the inability to set gantry crane walking tracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

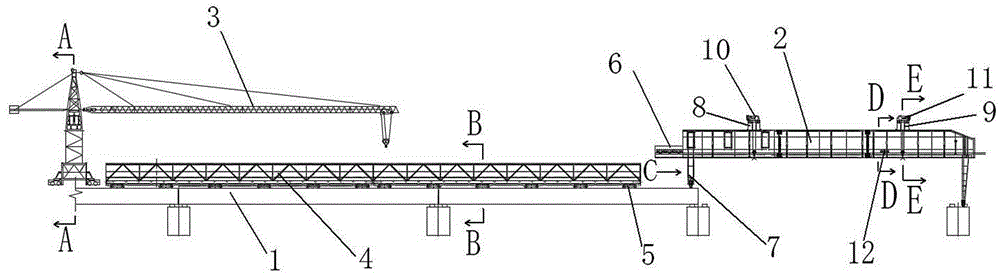

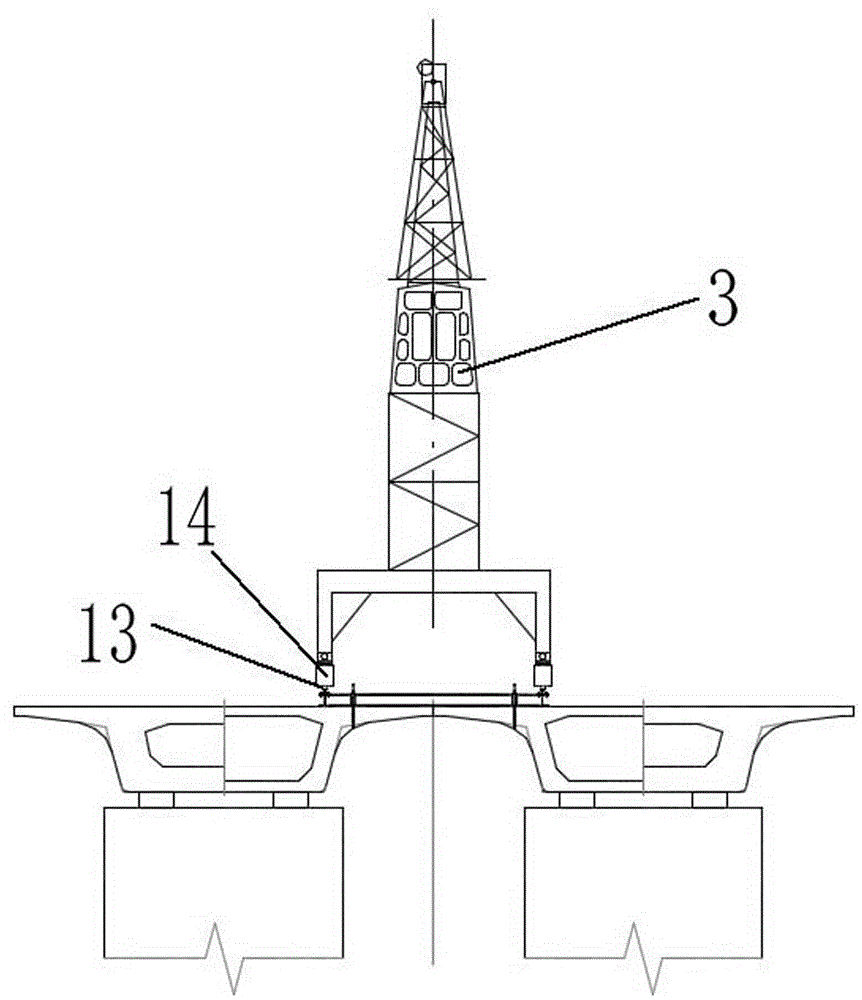

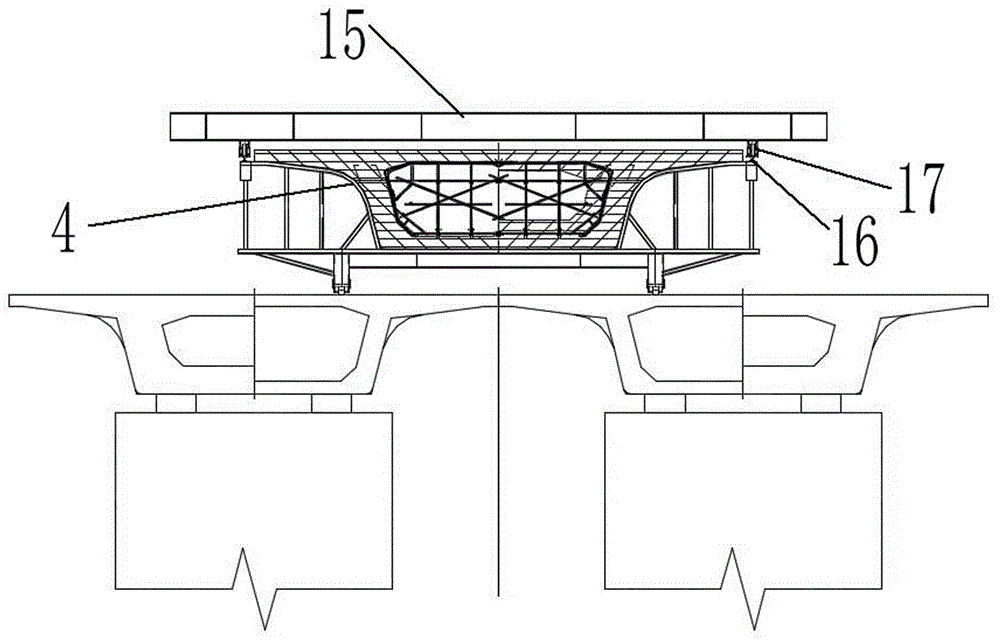

[0027] Attached below figure 1 to attach Image 6 The present invention will be further described.

[0028] The technical scheme that the present invention overcomes its technical problem adopts is:

[0029] The overall binding and hoisting construction method of the upward mobile formwork steel bar includes the following steps:

[0030] a) Concrete is poured at the reinforcement skeleton 18 in the outer formwork 22 to form a box girder; b) the poured box girder is subjected to equal-strength maintenance, tensioning, grouting and anchoring construction procedures; c) in step a) And while step b) is being constructed, a mold 4 is set on the concrete box girder that has been poured and formed in the previous hole, and the bottom plate reinforcement, web reinforcement, and prestressed steel of the next hole are bound on the mold 4 along the longitudinal direction. Bundle, assemble the inner mold, bind the roof reinforcement and pass the steel strands to finally form the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com