Deep-buried explosive compaction device

A technology of explosive silting and explosive packs, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of wasting explosive energy, reducing the effect of replacement, and slow formation of foundation pits, achieving good results and reducing the amount of explosives , the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

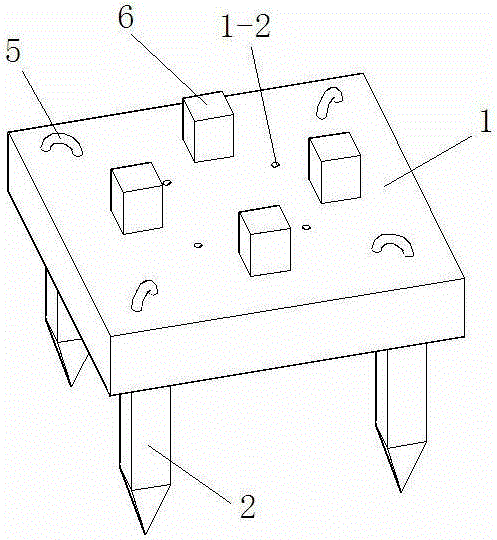

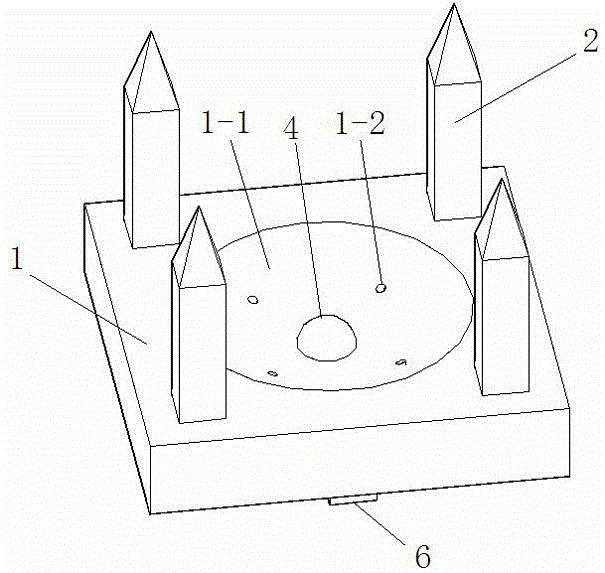

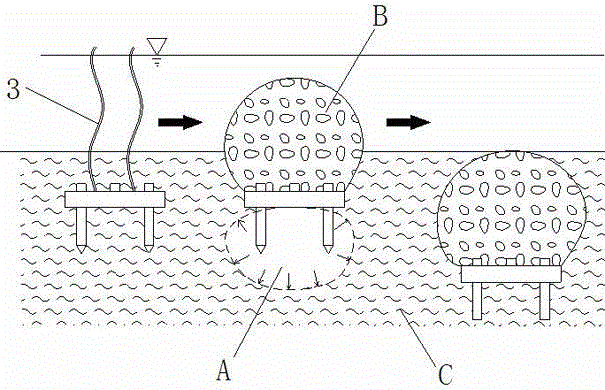

[0018] A deep-buried explosive silting device, the innovation of which is: the deep-buried explosive silting device is composed of a top plate 1, a plurality of pile feet 2, a plurality of suction pipes 3, an explosive package 4 and a suction dredger; The middle part of the lower surface of the top plate 1 is provided with a spherical groove 1-1, and the explosive package 5 is arranged in the middle of the bottom of the spherical groove 1-1; a plurality of pile feet 2 are arranged on the lower surface of the top plate 1, and a plurality of piles The foot 2 is located on the periphery of the spherical groove 1-1; the top plate 1 is provided with a plurality of suction holes 1-2 connecting the bottom of the spherical groove 1-1 and the upper end surface of the top plate 1, and the suction holes at the upper end surface of the top plate 1 The orifice of 1-2 forms a mud outlet, and the orifice of the mud suction hole 1-2 at the bottom of the spherical groove 1-1 forms a mud inlet; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com