Vibration-isolated construction method for ventilation air-conditioning machine room

A technology of air-conditioning equipment and construction methods, which is applied in the direction of air-conditioning systems, lighting and heating equipment, space heating and ventilation, etc. It can solve the problems of accelerating the discharge of indoor polluted air, insufficient fresh air, and accelerating the injection of outdoor fresh air, so as to reduce The vibration and noise reduction effect is obvious, the air ventilation is good and orderly, and the effect of improving the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing of description, the present invention will be further described.

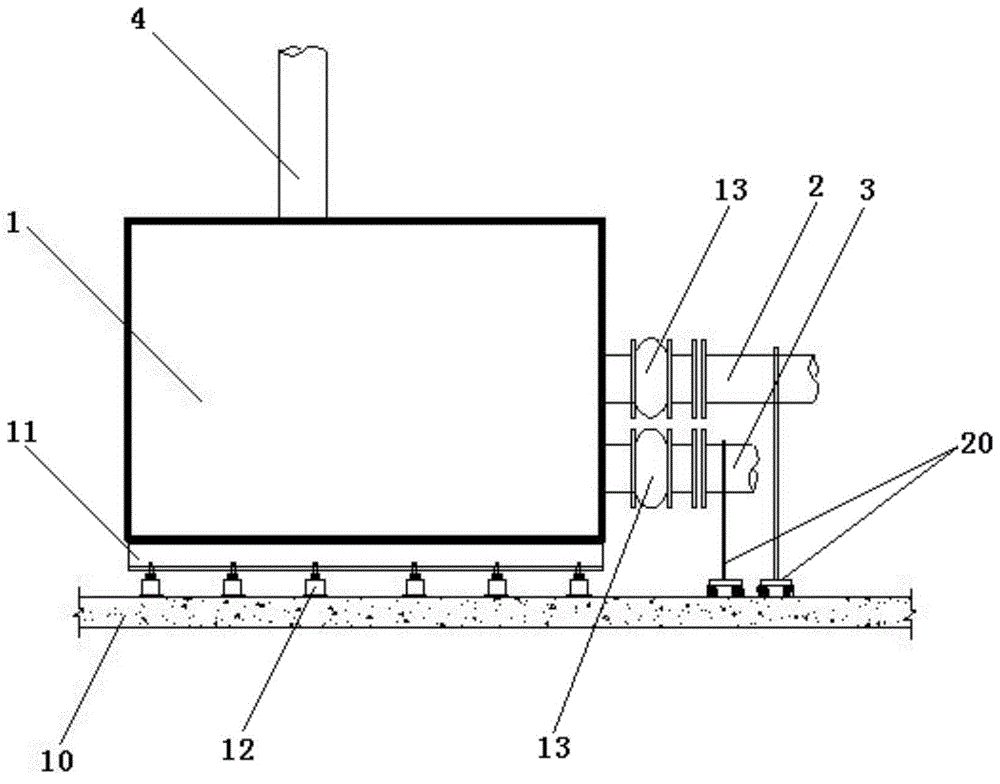

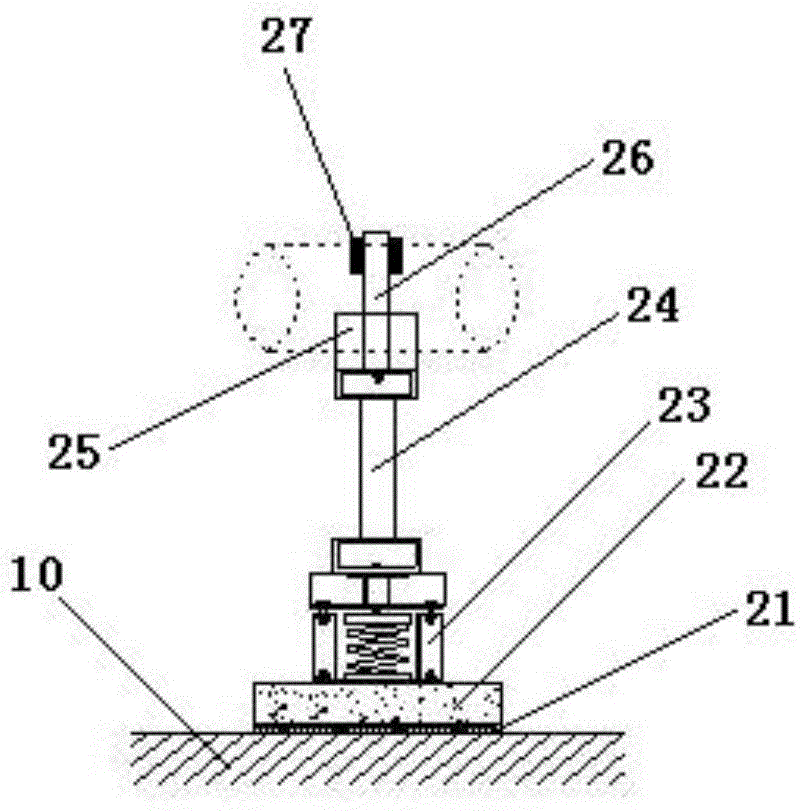

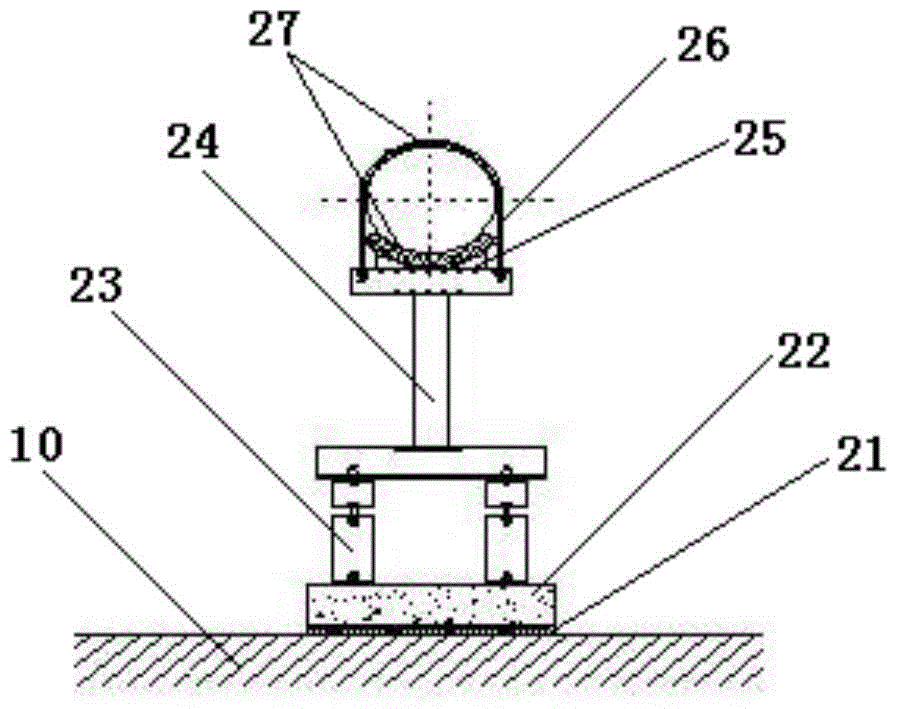

[0049] Such as figure 1 , figure 2 and image 3 The ventilation and air-conditioning equipment room shown is set on the equipment floor 10, including a refrigeration unit 1, a water inlet pipe 2 and an outlet pipe 3 connected to the refrigeration unit 1, and a fresh air pipe 4 connected to the refrigeration unit 1 and used for air supply.

[0050] The invention provides a seismic isolation construction method for a ventilation and air-conditioning equipment room, which includes the following seismic isolation construction steps:

[0051] Step 1: Install a steel-concrete mixed structure base 11 on the equipment floor 10, and install a damping spring shock absorber 12 between the steel-concrete mixed structure base 11 and the equipment floor 10; install the refrigerating unit 1 on the steel-concrete mixed structure base 11 on the upper surface, such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com