Tunnel multifunctional construction trolley

A construction trolley and multi-functional technology, applied in the field of tunnel machinery and tunnel multi-functional construction trolley, can solve the problems of complex maintenance, time-consuming, and high cost of machinery procurement, and achieve safe construction efficiency, fewer personnel required, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

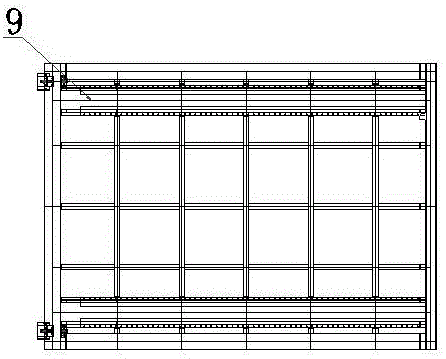

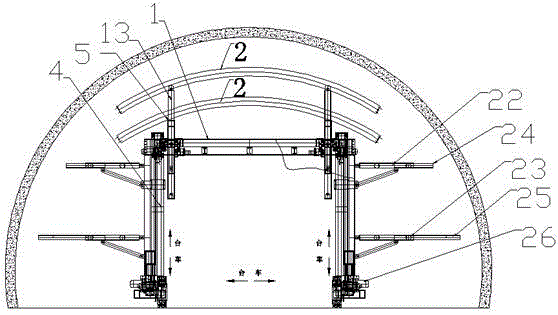

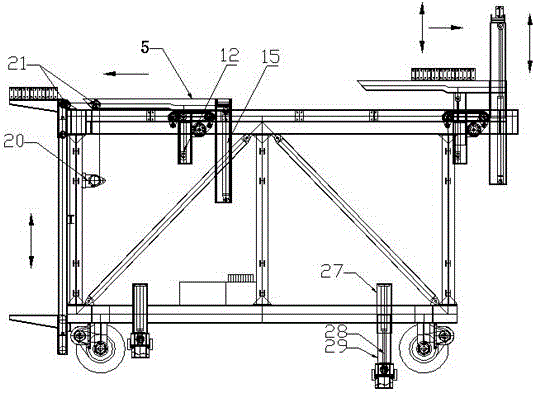

[0049] A tunnel multifunctional construction trolley, comprising a frame, a walking drive mechanism, a lifting mechanism, a transport mechanism, a lifting mechanism and an outrigger mechanism, a platform 1 is arranged on the top of the frame, and the lifting mechanism is arranged on the front of the frame It is used to lift the steel arch. The transport mechanism is set on the platform 1 to transport the steel arch lifted by the lifting mechanism. The lifting mechanism is fixed on the transport mechanism to lift the top arch 2 to the installation position. The outrigger mechanism is set on the frame The top is used to adjust the position of the frame, and the traveling drive mechanism is arranged at the bottom of the frame to drive the frame to move.

[0050] In the present invention, the lifting mechanism includes a delivery platform 3, a lifting track 4 and a lifting drive device. The lifting track 4 is two and is fixedly arranged on the front of the frame. The delivery platf...

Embodiment 2

[0062] In the present invention, the lifting mechanism is installed in the lifting mechanism track through rollers, and can move up and down through the lifting mechanism hoist. The rollers of the transport trolley are installed in the sunken track of the platform, driven by a hydraulic motor, and can move forward and backward on the platform. The telescopic beam of the bracket is installed in the sliding seat of the trolley frame. One end of the oil cylinder of the trolley is hinged with the telescopic beam, and the other end is hinged with the sliding seat of the frame.

[0063] The bracket is provided with a lifting arm sliding seat, and the lifting arm is installed therein. One end of the lifting arm oil cylinder is hinged with the lifting arm sliding seat, and the other end is hinged with the lifting arm.

[0064] exist figure 1 shows the process of lifting and transferring the steel arch by the bracket, in figure 2 The lifting process is shown in .

[0065] The metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com