A design method of LED collimating lens with double free-form surface

A technology of a collimating lens and a design method, which is applied to lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of increased space and cost of the collimation system, unfavorable modularization and application, etc. , to achieve the effect of improving energy collection rate and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

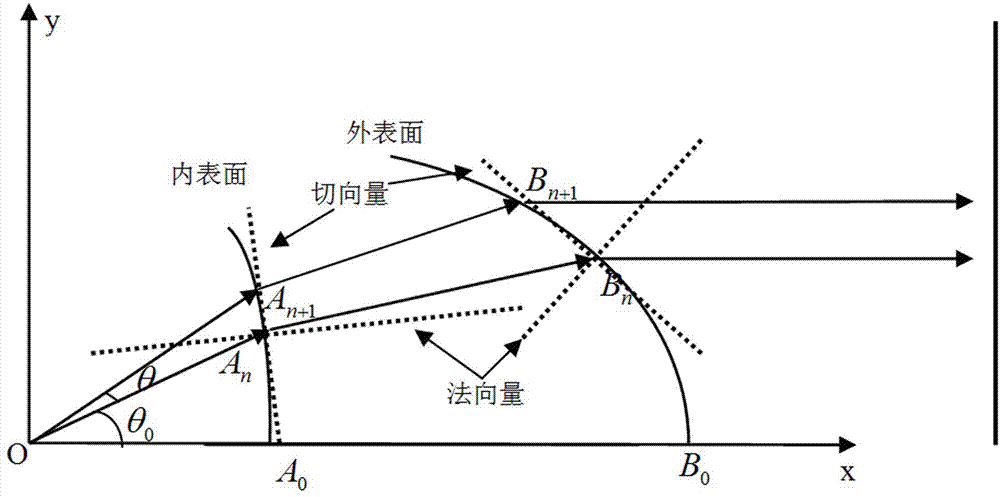

[0055] a) The lens material is polycarbonate (Pc), a highly light-transmitting material, whose refractive index is n=1.59, and the initial value A is introduced 1 Coordinates (12, 0.012), θ=0.001, B 1 The coordinates (25, 0.02), and the step size θ=0.001 are substituted into the iterative relationship in the above step 1, and the trajectory of the obtained coordinate points is as follows Figure 4 shown;

[0056] b) Import the discrete coordinate values of the trajectory obtained above into the proe 3D modeling software, and then automatically fit the above-mentioned coordinate lattice into a curve with a spline curve, and rotate it into a solid model, such as Figure 5 shown;

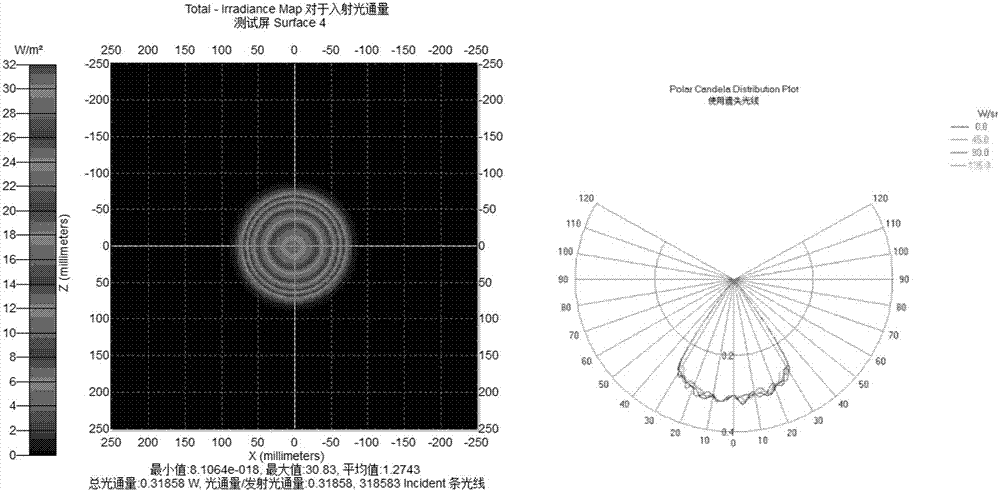

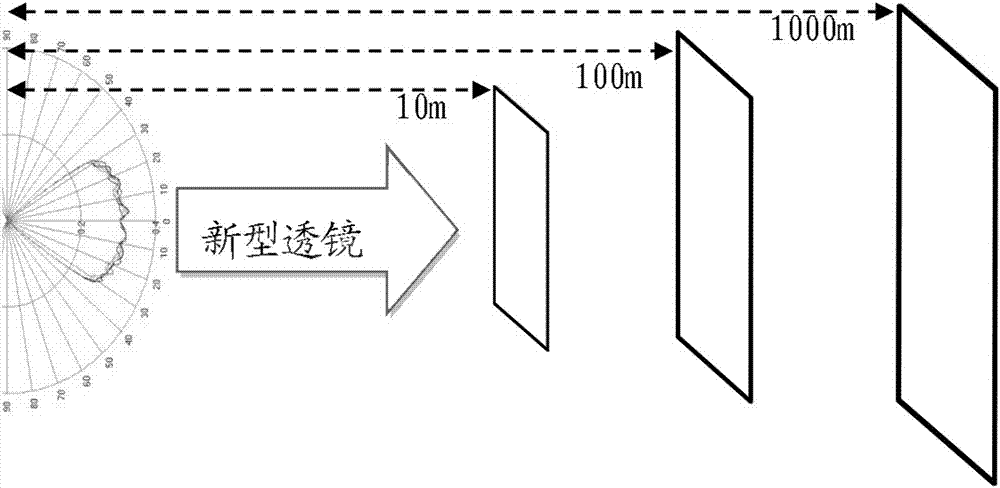

[0057] c) Import the solid model into TracePro optical simulation software for ray tracing simulation, verify and analyze the built model. Such as Figure 6 As shown, the illuminance distribution diagram of the target surface at the distance of 10 meters, 100 meters and 1000 meters from the LED l...

Embodiment 2

[0059] a) The lens material is polycarbonate (Pc), a highly light-transmitting material, whose refractive index is n=1.49, and the initial value A is introduced 1 Coordinates (12, 0.012), θ=0.001, B 1 The coordinates (40, 0.028), and the step size θ=0.001 are substituted into the iterative relationship in the above step 1, and the obtained trajectory coordinates are as follows Figure 7 shown;

[0060] b) Import the discrete coordinate values of the trajectory obtained above into the proe 3D modeling software, and then automatically fit the above-mentioned coordinate lattice into a curve with a spline curve, and rotate it into a solid model, such as Figure 8 shown;

[0061] c) Import the solid model into TracePro optical simulation software for ray tracing simulation, verify and analyze the built model. Such as Figure 9 As shown, the illuminance distribution diagram of the target surface at the distance of 10 meters, 100 meters and 1000 meters from the LED light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com