Online processing method for adjusting and controlling cigarette paper permeability

A processing method and technology for cigarette paper, which are applied in the directions of electrical program control, program control, and comprehensive factory control, etc., can solve problems such as difficulty in identifying genuine and fake cigarettes with cigarette paper, endangering the normal development of the cigarette industry, and harming the legitimate rights and interests of consumers, etc. The dilution effect is strengthened, the flue gas safety is improved, and the production efficiency is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

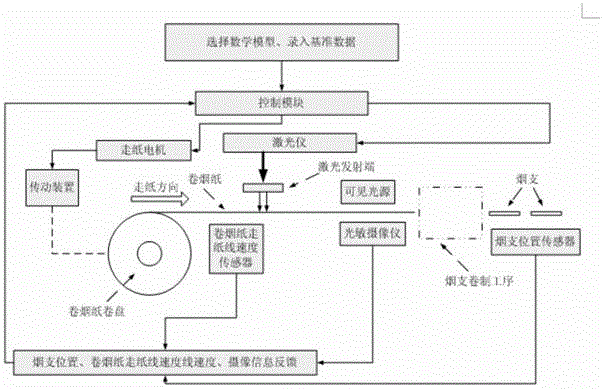

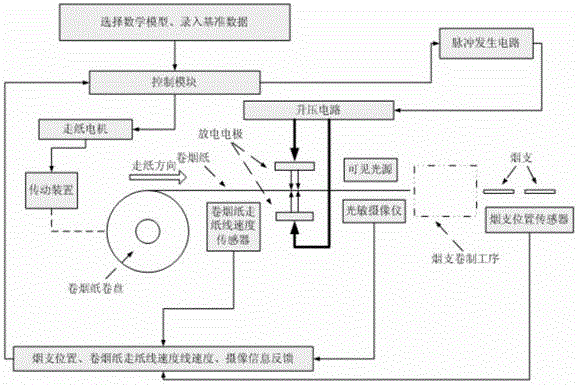

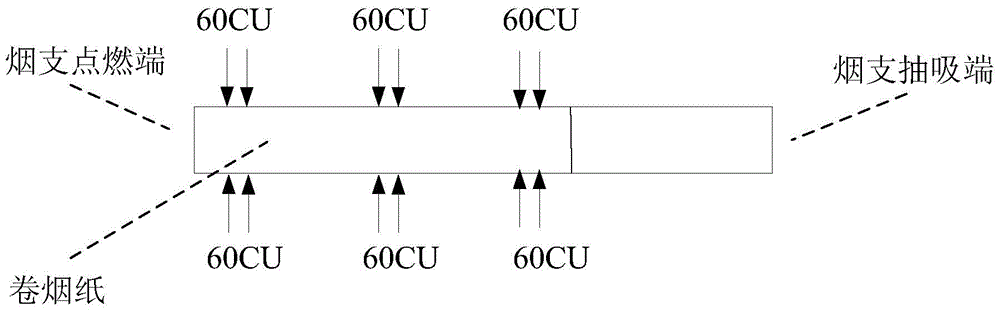

[0030] Example 1: Collecting benchmark data, including collecting cigarette paper from the cigarette rolling equipment, paper speed: 120m / min, cigarette length: 60mm, cigarette position: 1200mm from the laser emitting end or the electrostatic discharge electrode, manually input The initial air permeability within the length of the cigarette is 60CU, and the final air permeability is 60CU.

[0031] Selected mathematical model: y=60, where y represents air permeability, in CU, such as Figure 4 shown.

[0032] The control module solves the result: at any position, the number of laser or electrostatic drilling holes is 30 / 30mm 2 ;

[0033] The control module controls the laser part or the static electricity generating part, and uses the laser or the static electricity to break down the cigarette paper. At the same time, according to the cigarette paper feeding speed, cigarette length and position parameters fed back by the sensor, the position and number of punching holes are ...

Embodiment 2

[0035] Example 2: Collecting benchmark data, including collecting cigarette paper from the cigarette rolling equipment, paper speed: 120m / min, cigarette length: 60mm, cigarette position: 1200mm from the laser emitting end or the electrostatic discharge electrode, manually input Within the length of the cigarette, the initial air permeability is 40 CU, and the final air permeability is 80 CU.

[0036] Mathematical model selected: y=(120+2x) / 3, where y represents air permeability, in CU; x represents the length of cigarettes, ranging from 0 to 60, in mm, such as Image 6 shown.

[0037] The control module solves the result: within the range of 60mm per unit length (that is, the length of the cigarette), the number of laser or electrostatic perforations is an increasing function, from 20 / 30mm 2 Incremented to 40 / 30mm 2 , and repeat the implementation within the unit length.

[0038] The control module controls the laser part or the static electricity generating part, and uses ...

Embodiment 3

[0040]Example 3: Collecting benchmark data, including collecting cigarette paper from the cigarette rolling equipment, paper speed: 120m / min, cigarette length: 60mm, cigarette position: 1200mm from the laser emitting end or the electrostatic discharge electrode, manually input Within the length of the cigarette, the initial air permeability is 80CU, and the final air permeability is 40CU.

[0041] Mathematical model selected: y=(240-2x) / 3, where y represents air permeability, in CU; x represents the length of cigarettes, ranging from 0 to 60 mm, in mm, such as Figure 8 shown.

[0042] The control module calculates the result: within the range of 60mm per unit length (that is, the length of the cigarette), the number of laser or electrostatic perforations is in a decreasing function, from 40 / 30mm 2 Increment to 20 / 30mm 2 , and repeat the implementation within the unit length.

[0043] The control module controls the laser part or the electrostatic discharge electrode, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com