Automatic-winding-device-based rotary transformer winding method

A rotary transformer and automatic winding technology, which is applied in the manufacture of transformers, inductors, coils, etc., can solve the problems of low production efficiency and survival rate, error-prone, time-consuming, etc., and achieve improved survival rate, production efficiency, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with description the present invention is described in detail:

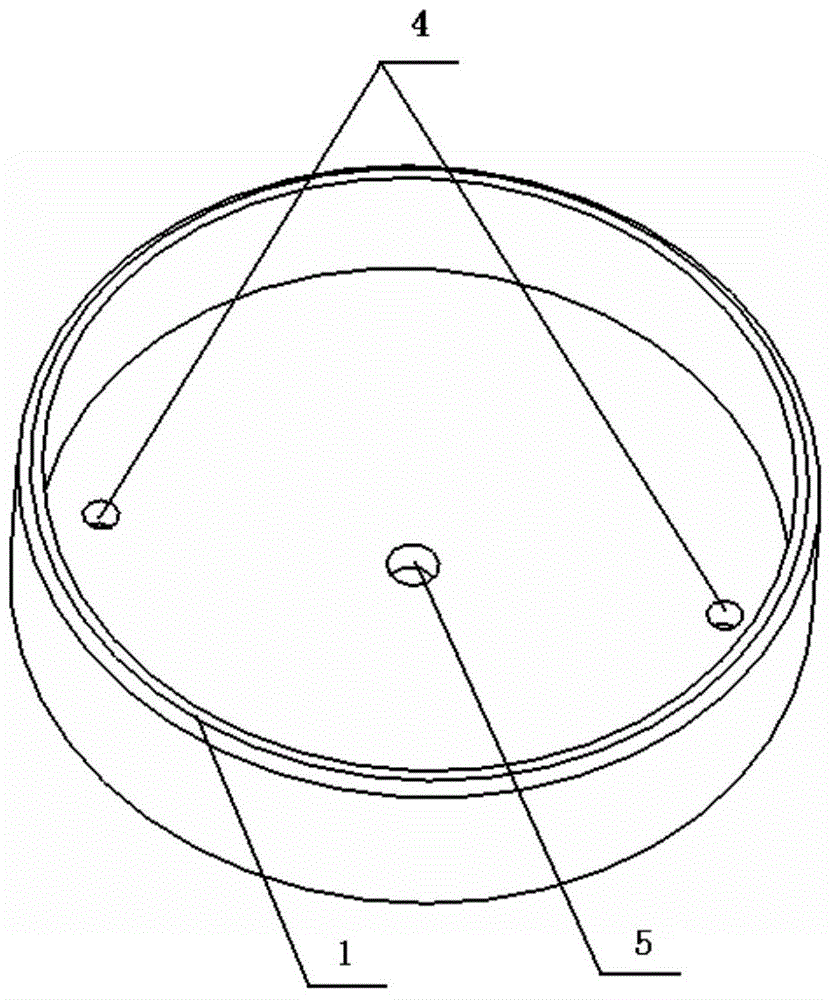

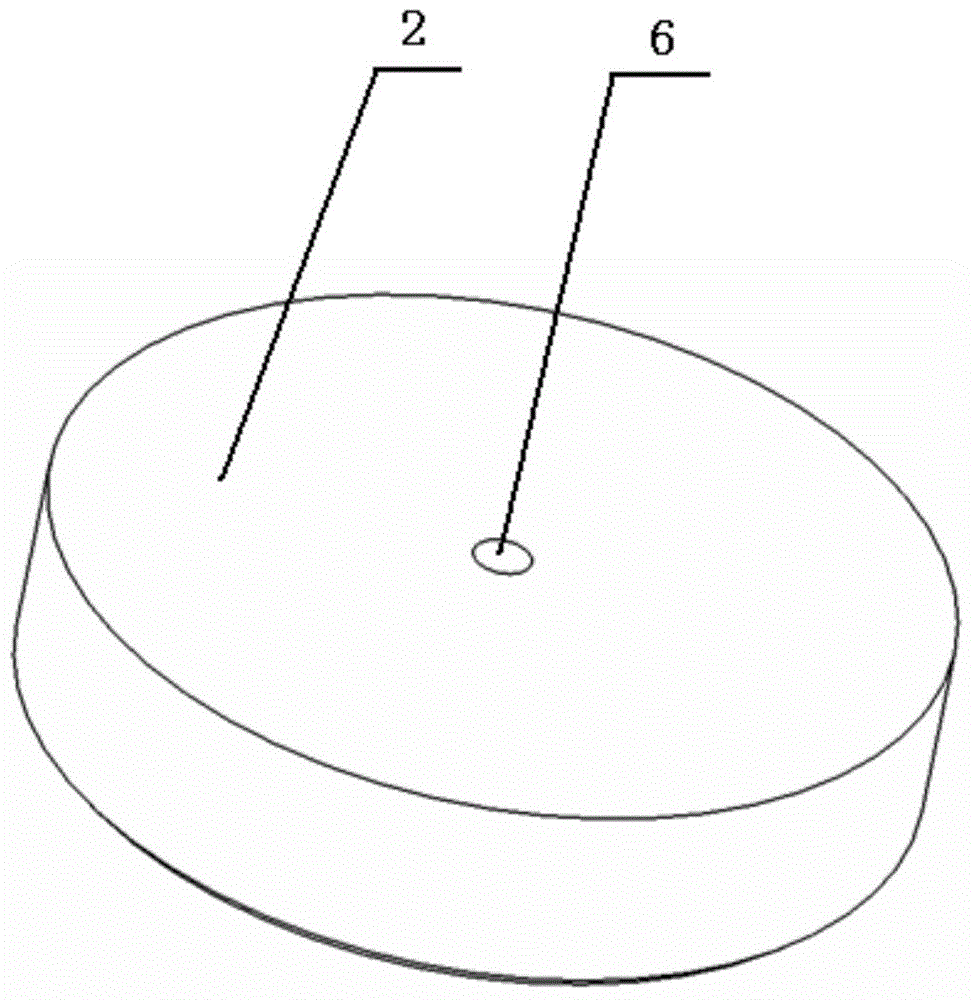

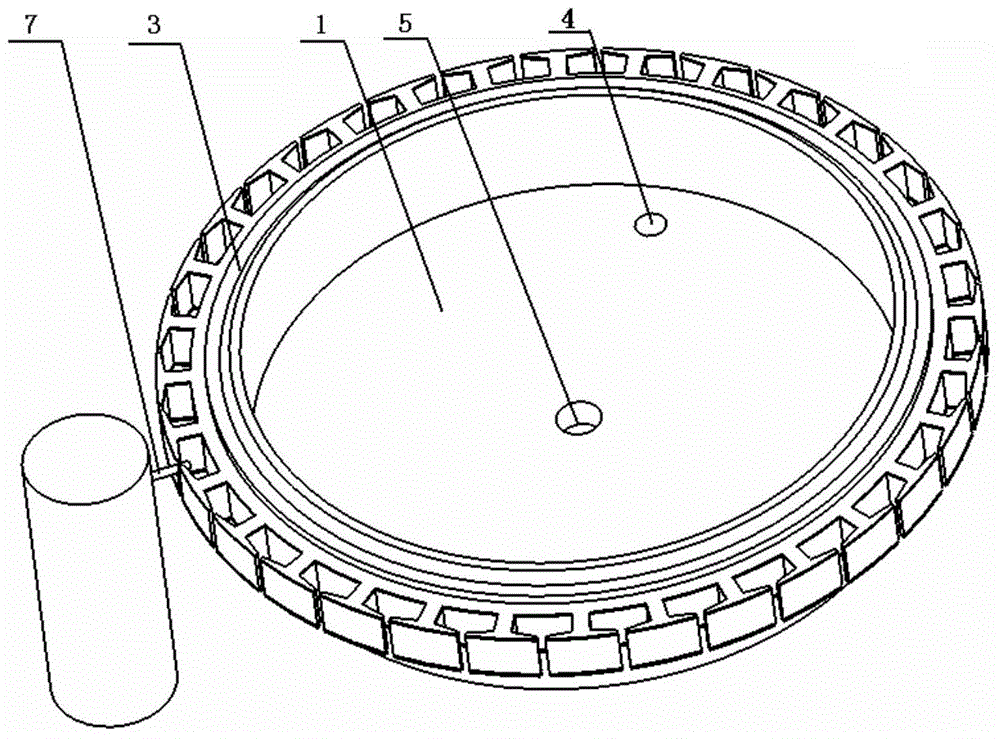

[0017] Step 1: Processing a positioning tool for fixedly connecting the resolver core 3, the positioning tool is formed by connecting the bottom part 1 and the top part 2; the bottom part 1 is a hollow cylinder whose diameter matches the inner diameter of the resolver core 3 The outer edge of the bottom of the bottom part 1 cavity is provided with a plurality of fixed threaded holes 4 connected to the winding machine, and the bottom center of the cavity is provided with a threaded hole 5 for connecting the top part 2; the top part 2 is connected with the bottom part 1 A hollow cylinder with matched diameters, the top center of which is provided with a top threaded hole 6 connected to the bottom part 1; the bottom part and the top part are made of stainless steel;

[0018] Step 2: Insulate the iron core of the resolver by adopting the insulating treatment method of static definite coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com