Method and apparatus for reducing aflatoxin-contaminated corn

A technology for aflatoxin and corn, applied in chemical instruments and methods, applications, wet separation, etc., can solve the problems of sampling variation and batch product testing being too high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

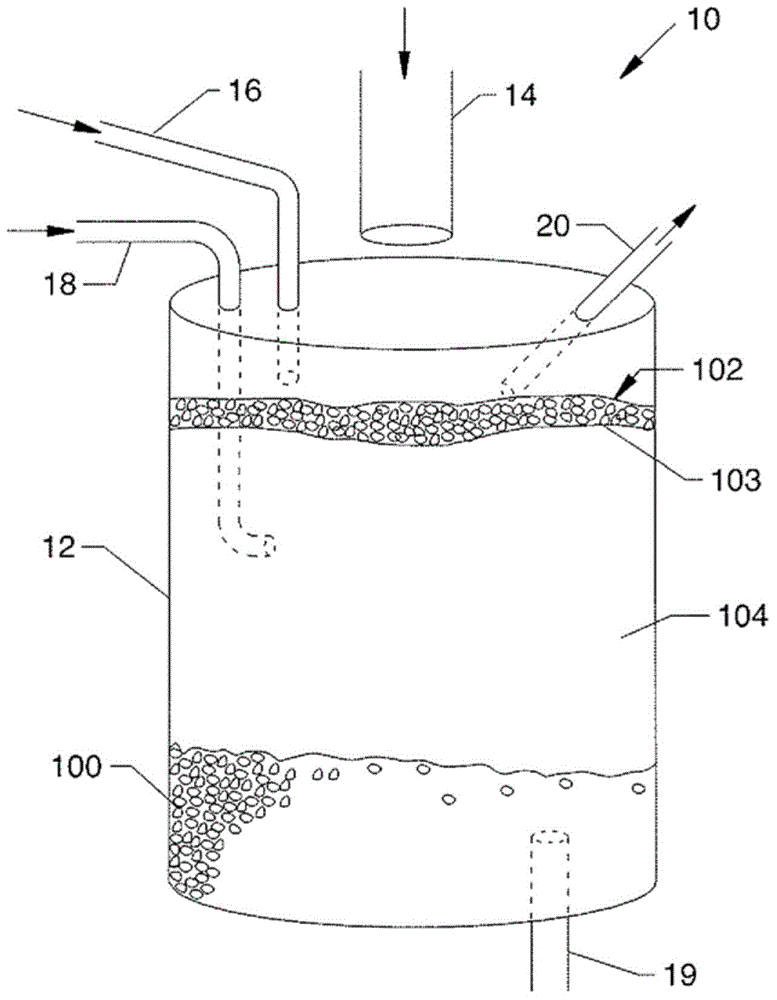

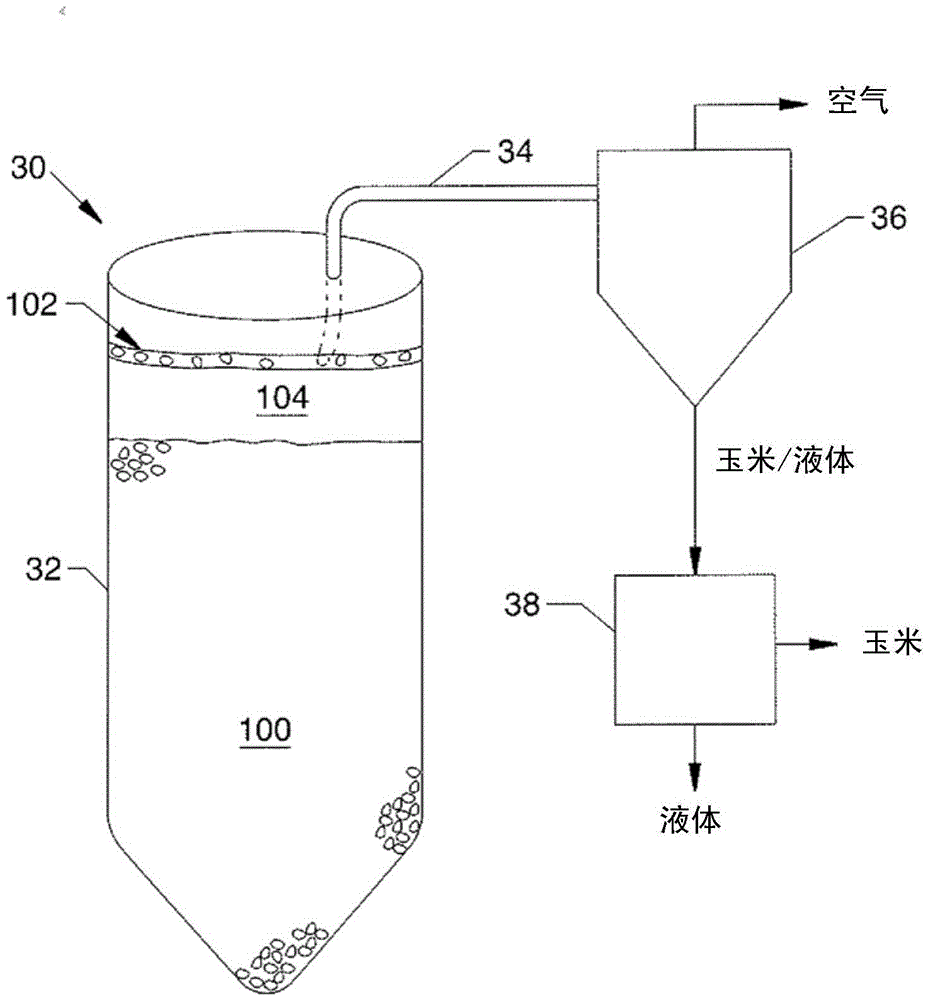

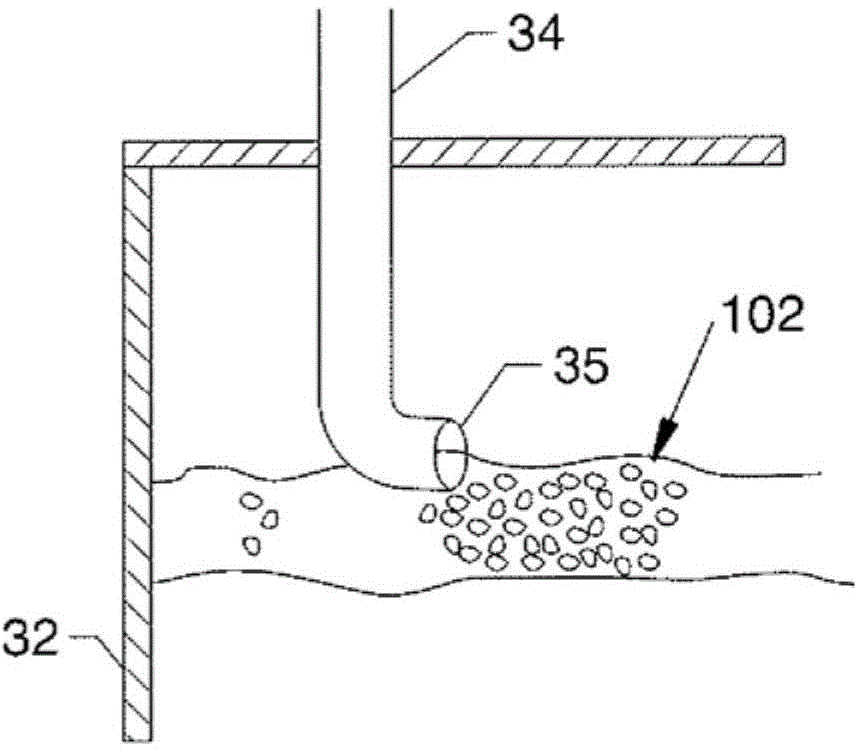

[0067] The flotation and separation processes of the present disclosure were run at laboratory scale, pilot plant scale and commercial scale.

[0068]In accordance with the methods of the present disclosure, corn batches that have been screened to remove rot but not otherwise processed are processed. For Examples 1-12, corn was obtained from a first source, and for Examples 13-25, corn was obtained from a second (different) source. Aflatoxin-contaminated corn was separated from less-contaminated corn by flotation on light soak water (LSW) or diluted LSW. Unless otherwise noted, LSW has a Baume (Be) of 6 at a temperature of 60°F. Floating mats of contaminated corn were removed by: (a) overflowing and sifting corn in laboratory experiments, (b) screening corn in pilot-scale experiments, (c) sifting, overflowing in pilot-scale experiments flow or overflow method, and (d) suction or vacuum method or overflow or overflow method in commercial scale experiments.

[0069] By adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com