Common mussel powder for effectively decreasing activity of aflatoxin and preparation method of common mussel powder

A technology of aflatoxin and shell powder, applied in the direction of inorganic non-surface-active cleaning compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

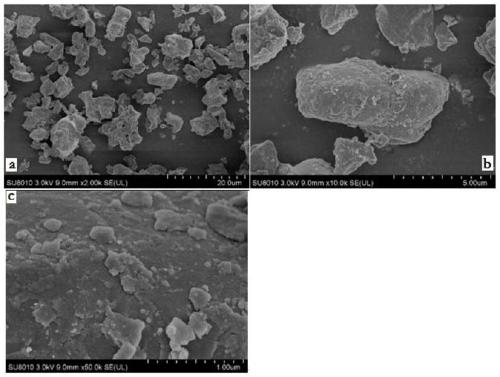

[0036] The invention discloses a preparation method of active blue mussel shell powder which can effectively reduce aflatoxin, comprising the following steps:

[0037] Step 1. Select the current year's purple mussel shell as raw material;

[0038] Preferably, the raw material is selected from fresh blue mussel shells with excellent water quality and pollution-free cultivation in the sea area. The blue mussel shells have low heavy metal content and quality is guaranteed; preferably, the raw materials are selected from current year blue mussel shells from Gouqi Island, Zhoushan, Zhejiang.

[0039] Step 2, cleaning and screening shells;

[0040] Step 3, peeling off the coat of the purple mussel shell: peeling off the coat of the purple mussel shell by physical means;

[0041] Among them, the physical method is: use a brush stick to roll and scrub, use air pressure and water waves to repeatedly wash, and then vibrate and sieve to peel off the outer layer of the purple mussel shel...

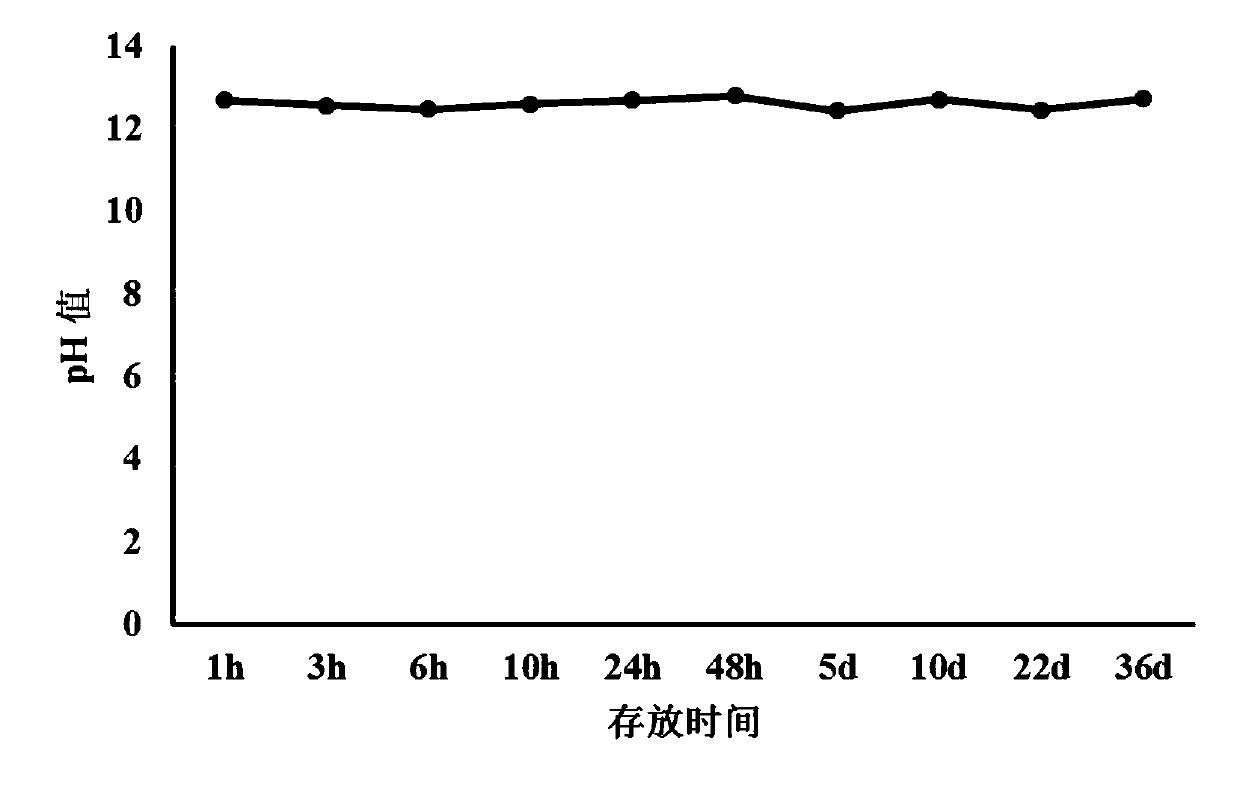

Embodiment 1

[0055] A kind of preparation method of the active blue mussel shell powder of effectively reducing aflatoxin, comprises the following steps:

[0056] Step 1. Select the current year's purple mussel shell as raw material;

[0057] Preferably, the raw material is selected from fresh blue mussel shells with excellent water quality and pollution-free cultivation in the sea area. The blue mussel shells have low heavy metal content and quality is guaranteed; preferably, the raw materials are selected from current year blue mussel shells from Gouqi Island, Zhoushan, Zhejiang.

[0058] Step 2, cleaning and screening shells;

[0059] Step 3, peeling off the coat of the purple mussel shell: peeling off the coat of the purple mussel shell by physical means;

[0060] Among them, the physical method is: use a brush stick to roll and scrub, use air pressure and water waves to repeatedly wash, and then vibrate and sieve to peel off the outer layer of the purple mussel shell;

[0061] Since...

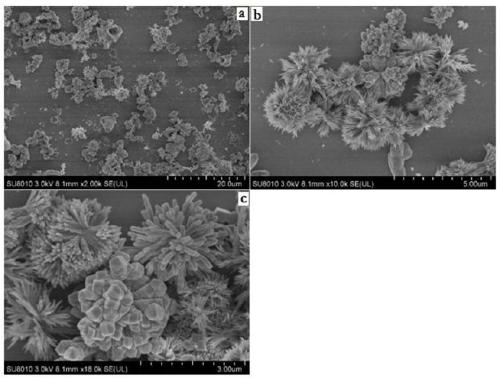

Embodiment 2

[0075] A kind of preparation method of the active blue mussel shell powder of effectively reducing aflatoxin, comprises the following steps:

[0076] Step 1. Select the current year's purple mussel shell as raw material;

[0077] Preferably, the raw material is selected from fresh blue mussel shells with excellent water quality and pollution-free cultivation in the sea area. The blue mussel shells have low heavy metal content and quality is guaranteed; preferably, the raw materials are selected from current year blue mussel shells from Gouqi Island, Zhoushan, Zhejiang.

[0078] Step 2, cleaning and screening shells;

[0079] Step 3, peeling off the coat of the purple mussel shell: peeling off the coat of the purple mussel shell by physical means;

[0080] Among them, the physical method is: use a brush stick to roll and scrub, use air pressure and water waves to repeatedly wash, and then vibrate and sieve to peel off the outer layer of the purple mussel shell;

[0081] Since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com