drive unit

A driving device and motor technology, applied in the direction of electromechanical devices, circuit devices, electric components, etc., can solve the problems of disconnection volume and increase, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Hereinafter, a mounting machine used when forming an integrated circuit on a circuit board will be described with reference to the drawings. The integrated circuits on the circuit board are transported and formed in the order of a solder printer, a mounting machine, and a reflow oven. The solder printing machine prints solder paste on the mounting positions of the electronic components on the circuit board. The mounting machine mounts electronic components at mounting positions on a circuit board on which solder paste is printed. A reflow oven solders electronic components to a circuit board by applying heat treatment to the circuit board.

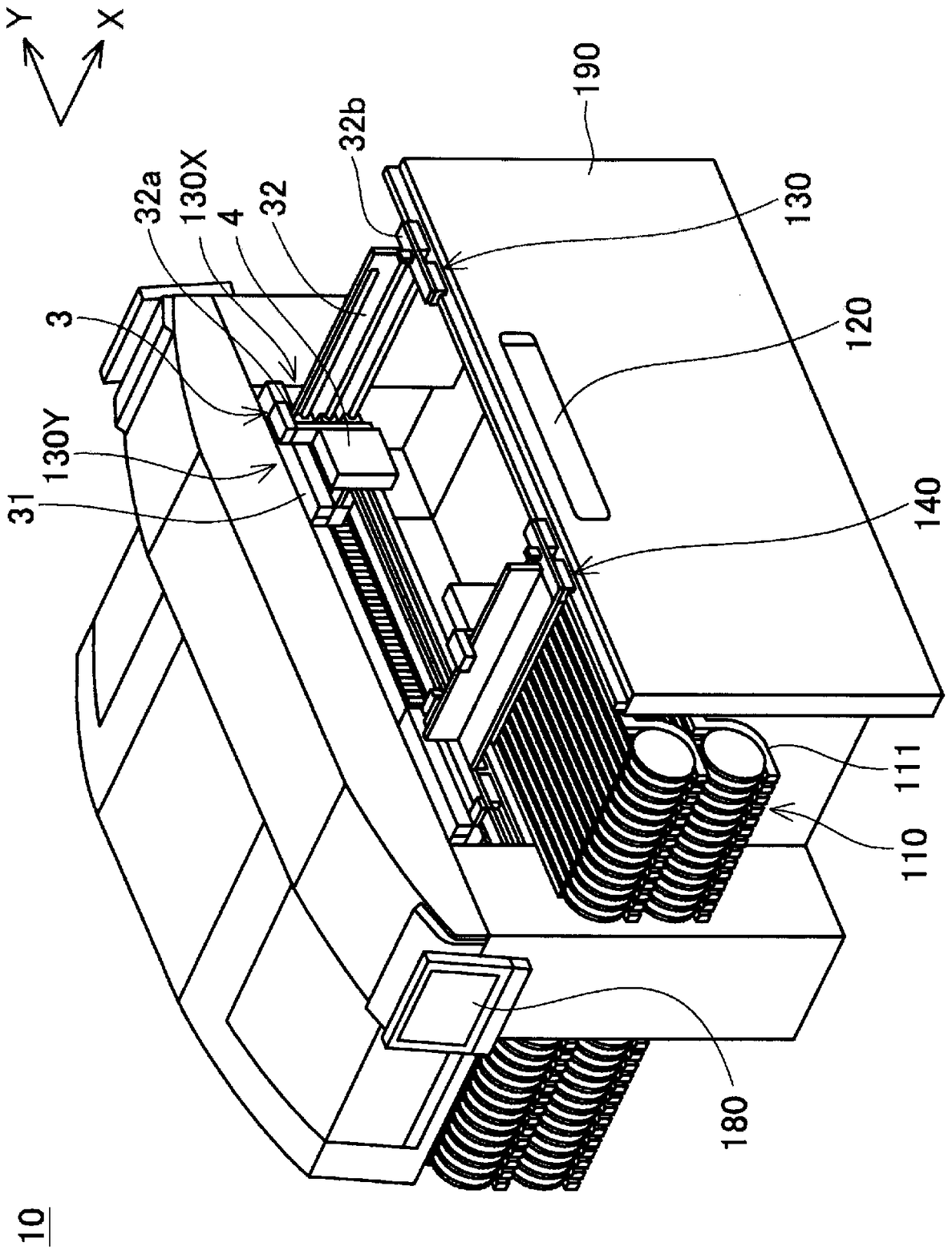

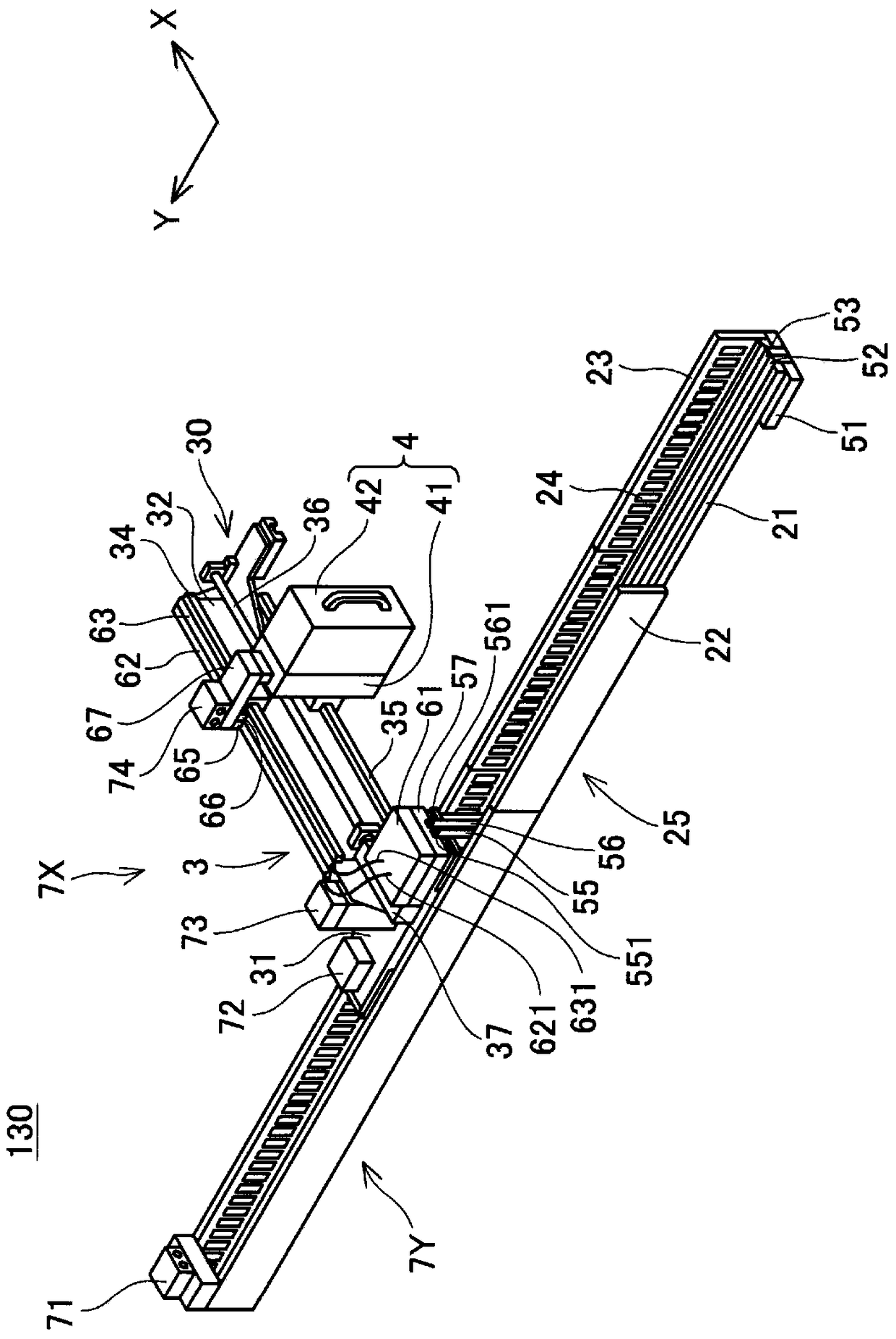

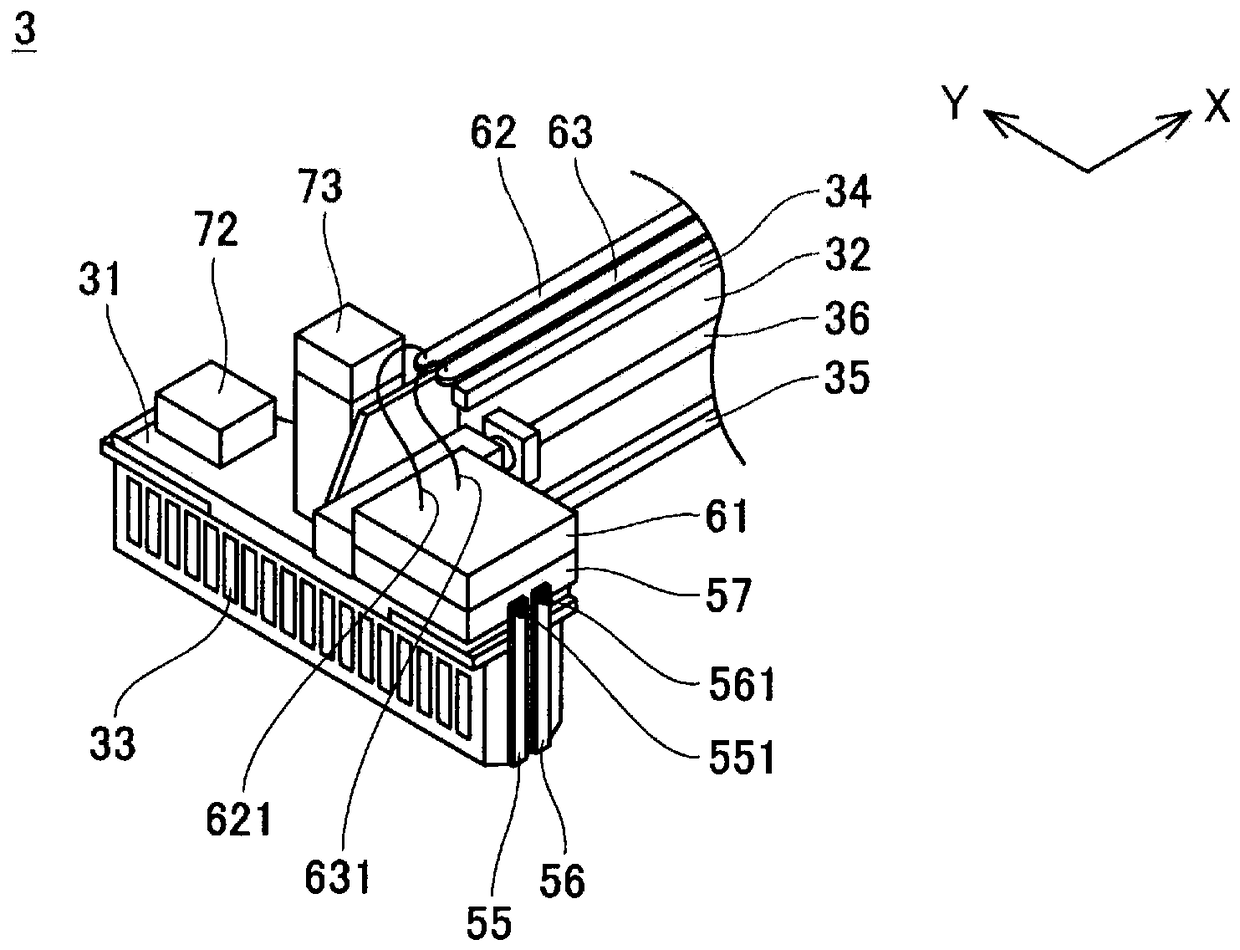

[0025] Such as figure 1 As shown, the mounting machine 10 includes two modules arranged adjacently, and each module has a common structure. figure 1 Indicates that the outer cover plate of one of the two modules has been removed. Each module includes a component supply device 110 , a substrate transfer device 120 , two component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com