Vibration platform for concrete pipe pouring

A vibrating platform and concrete pipe technology, applied in clay preparation devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of poor vibration effect of vibration components, inconsistent segmentation and strength, uneven concrete mixing, etc., to solve the overall problem. Inconsistent strength, good casting effect, wall thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

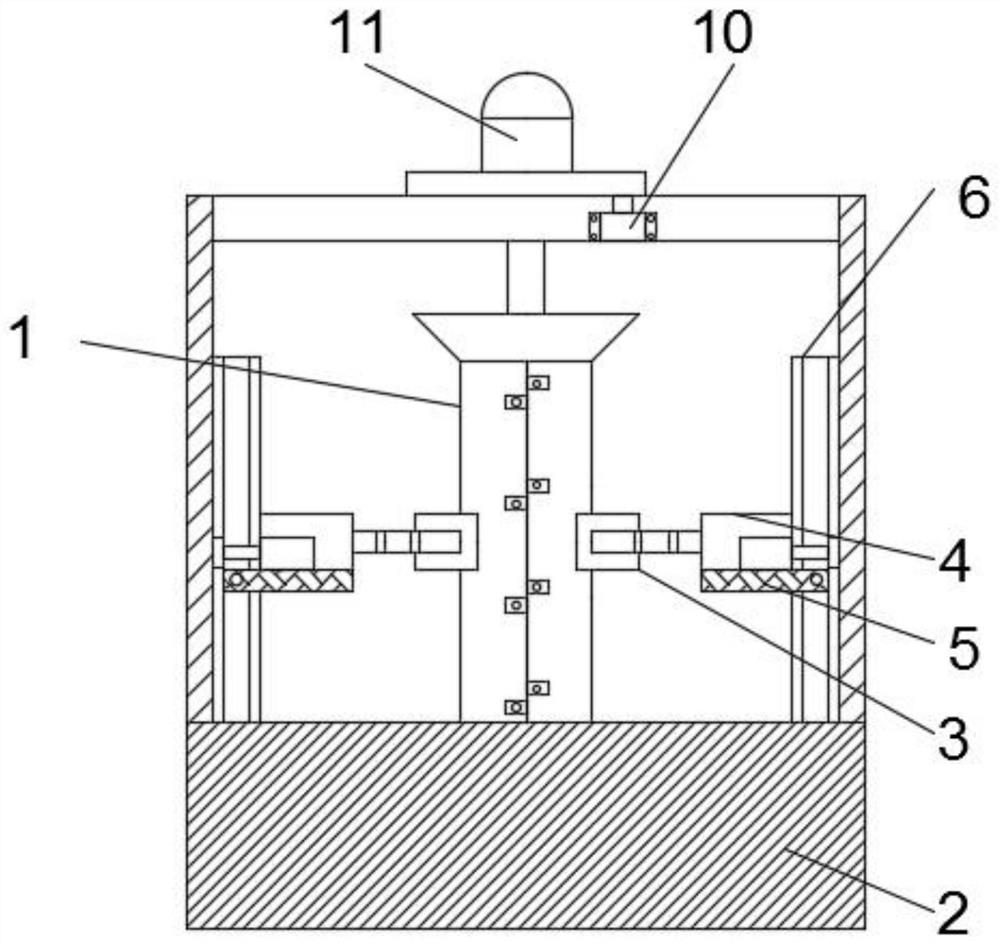

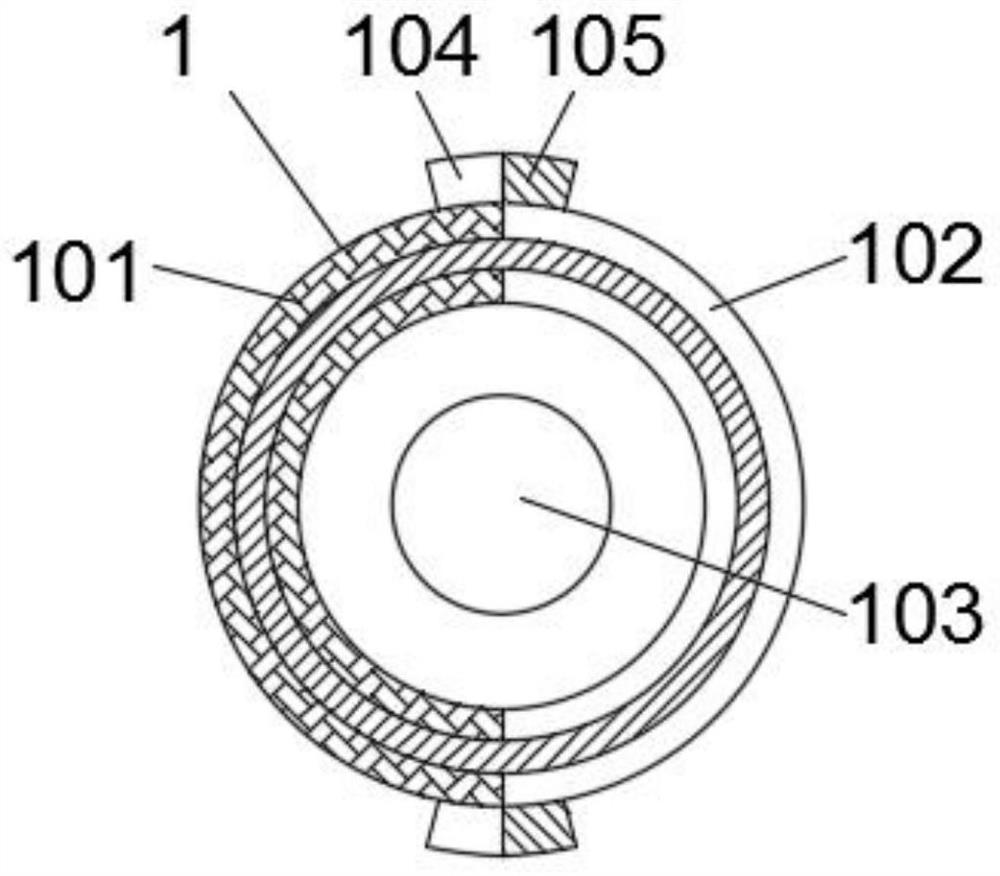

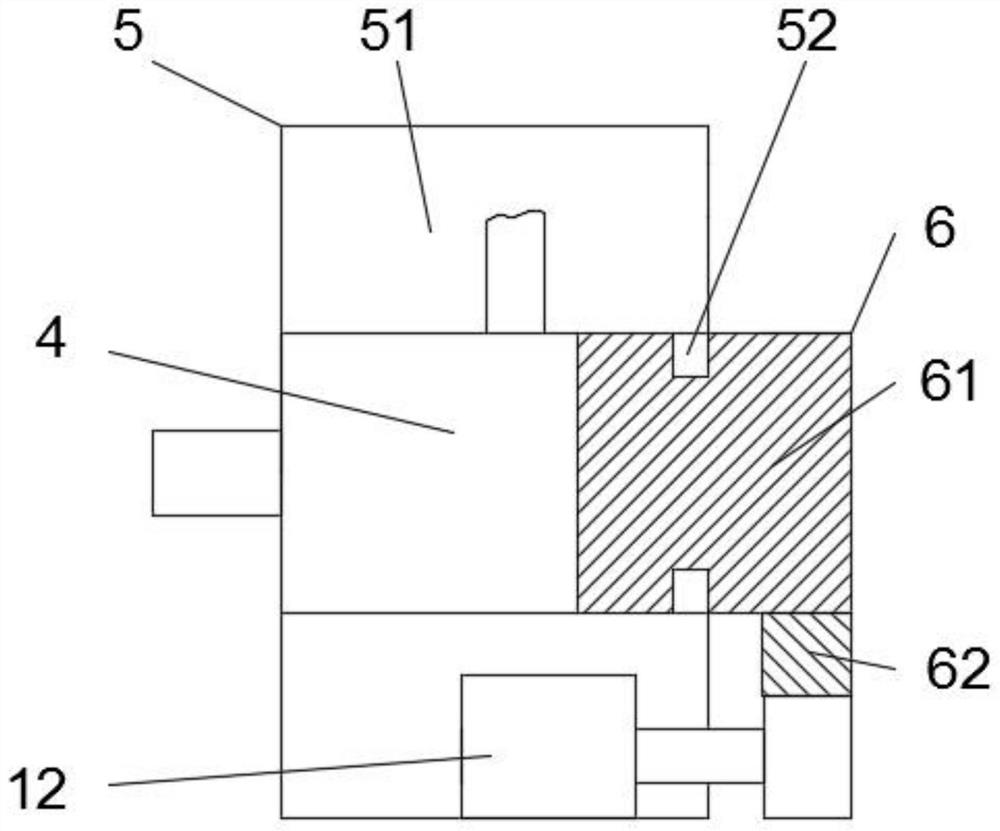

[0045] First start the cylinder 10 to lift the stirring mechanism 11 upwards, mold one 101 is provided with a slot one adapted to the fixed plate one 104, and the mold two 102 is provided with a slot two adapted to the fixed plate two 105, and mold one 101 and mold two 102 are clamped, and then bolted through the bolt holes provided on the fixing plate two 105 and the fixing plate one 104, a funnel is installed on the upper end of the casting mold mechanism 1, and a funnel corresponding to the funnel is arranged on the upper surface of the casting mold mechanism 1. Adapted funnel groove, the funnel is inserted into the pouring mold mechanism 1 through the funnel groove, and then pours the mixed concrete into the funnel. The area is filled and poured at one time, without the problem of broken joints, and the pouring effect is better; the structure of diffusion mechanism 1 3 and diffusion mechanism 2 15 is the same, the structure of protection mechanism 1 4 and protection mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com