High-pressure rotary spraying anchor cable structure for building anti-floating and construction method thereof

A high-pressure rotary spraying and building technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of difficult formation of grouting body, waste of resources, poor stability and adaptability, etc., and achieve good pouring effect and dust free Less pollution and less impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

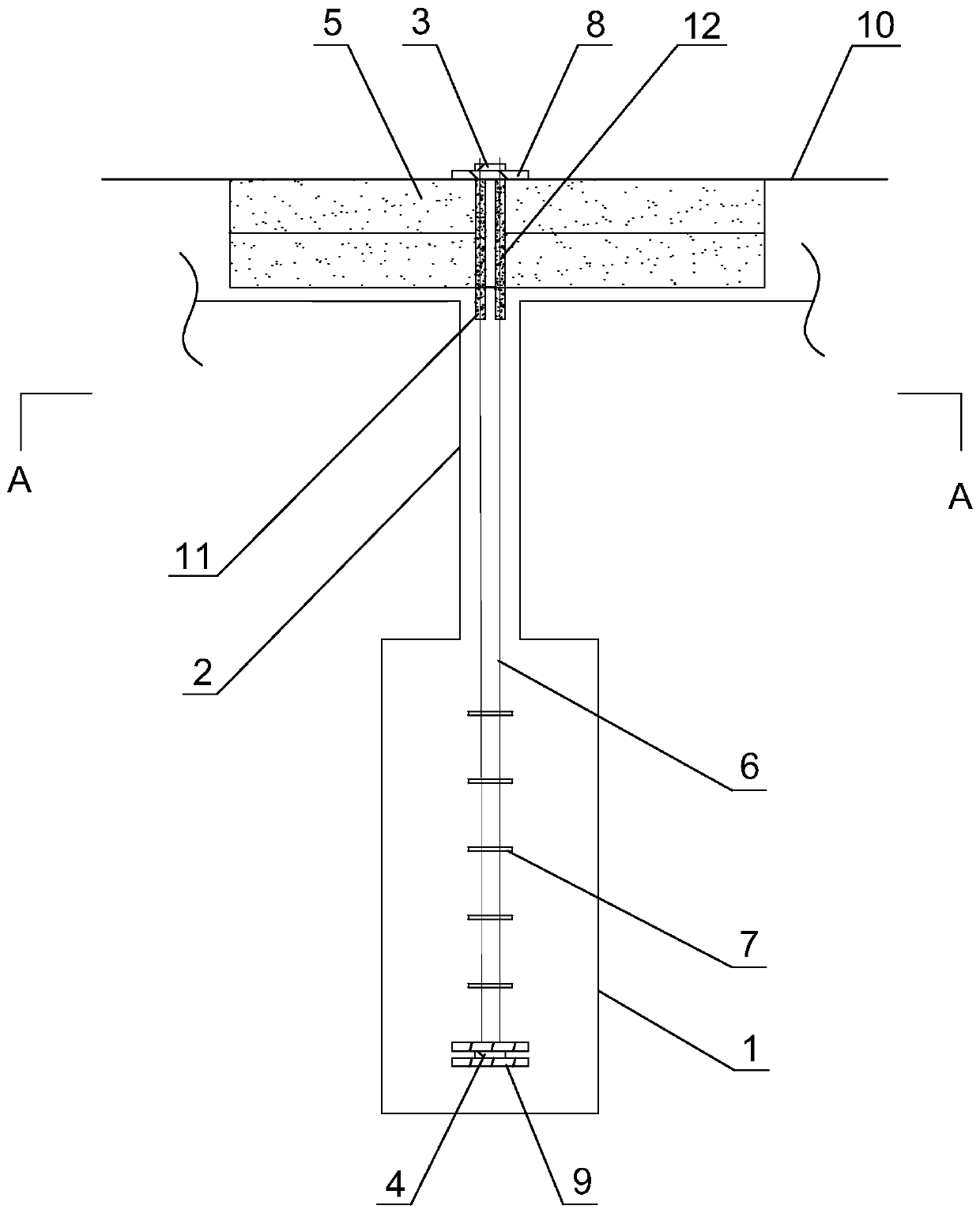

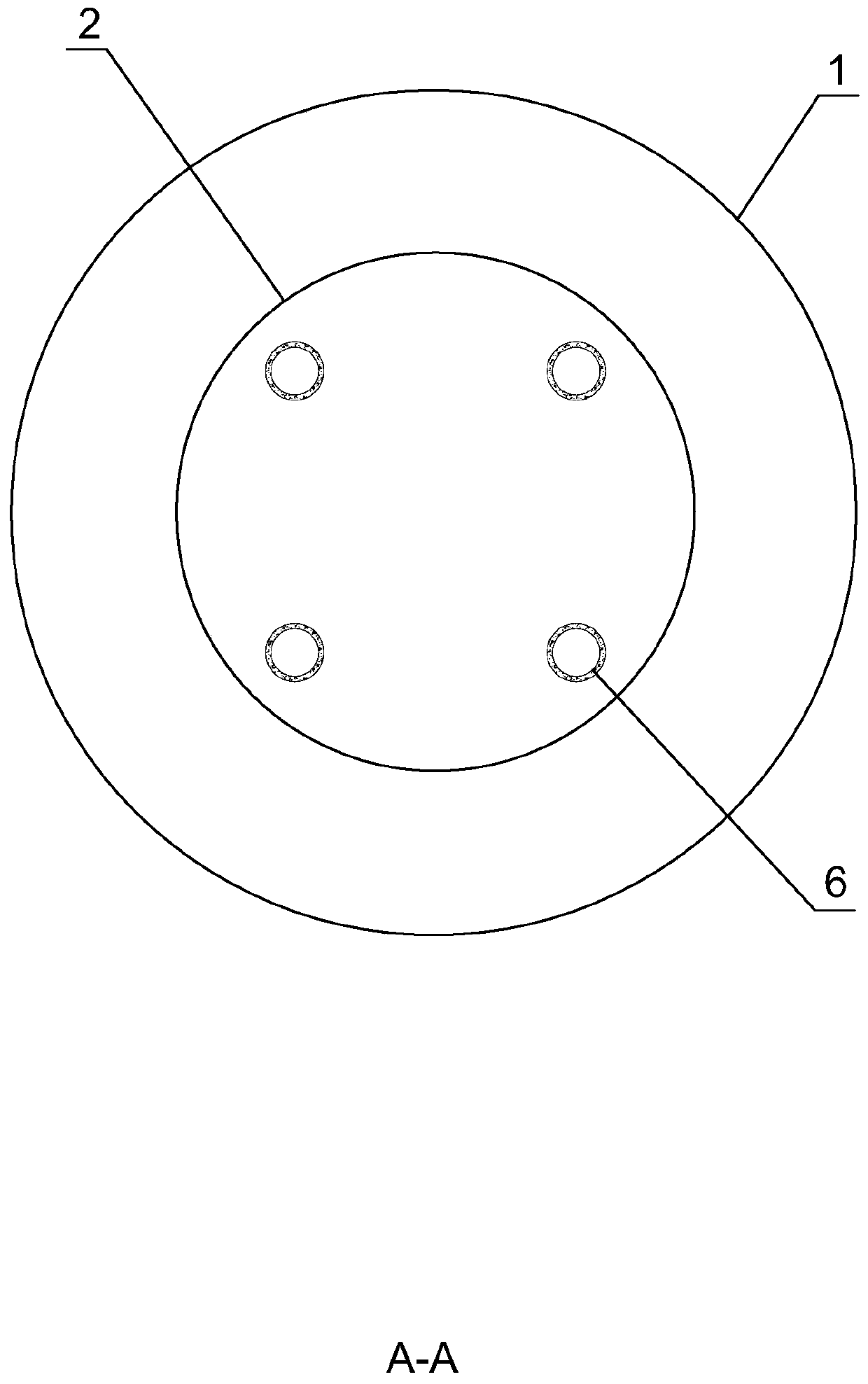

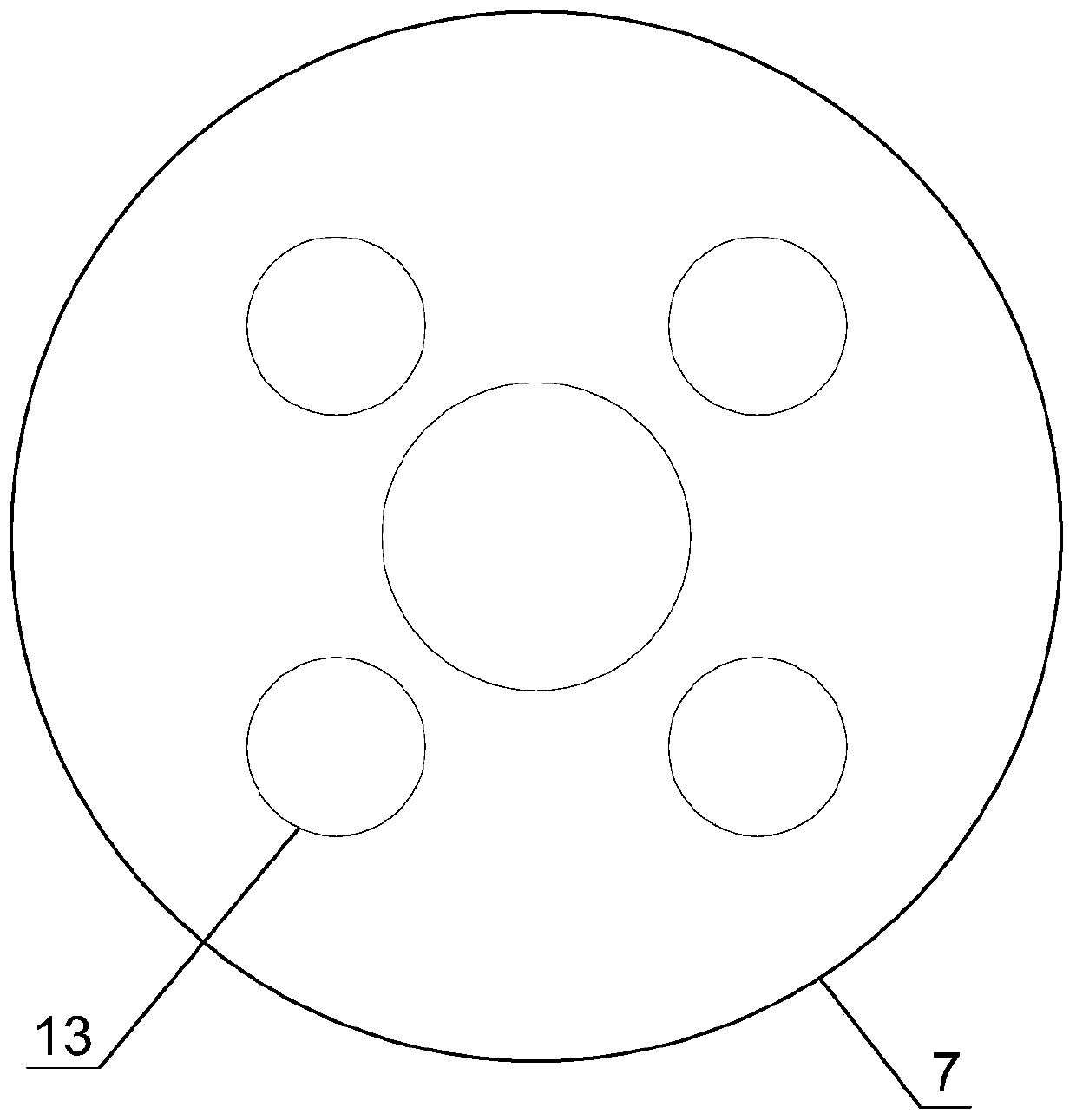

[0048] refer to figure 1 , is a high-pressure jet grouting anchor cable structure for building anti-floating disclosed in the present invention, including a cement grouting body 1 and a cement-soil mixture 2 fixedly connected with the cement grouting body 1 . During the construction process, use the high-pressure jet-jet equipment to control the high-pressure jet-jet drill to carry out the drilling work. After the pile hole is formed, lift the drill pipe and the high-pressure jet-jet drill, and continue to control the high-pressure jet-jet drill in the pile hole through the high-pressure jet-jet equipment. For high-pressure spraying, first pour the cement grouting body 1 at the bottom of the hole until there is no groundwater seepage, and then pour the cement-soil mixture 2 on the basis of the cement grouting body 1. Grouting in this way, It can greatly redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com