Shear wall casting molding mould and usage method thereof

A pouring forming and shear wall technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of deformation and cracking of shear walls, low construction quality, large manpower and material resources, etc. , to achieve the effect of low construction cost, good pouring effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

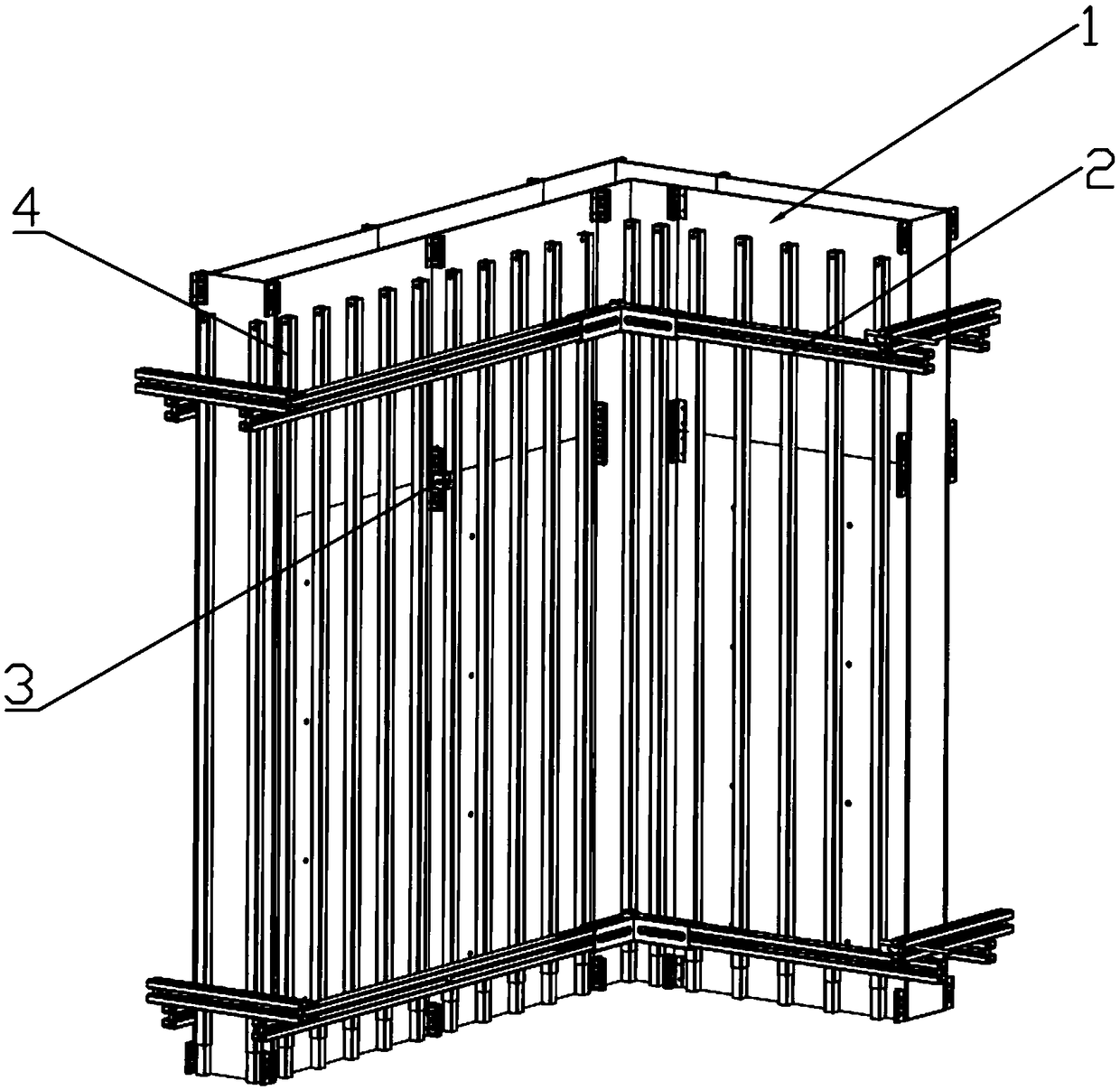

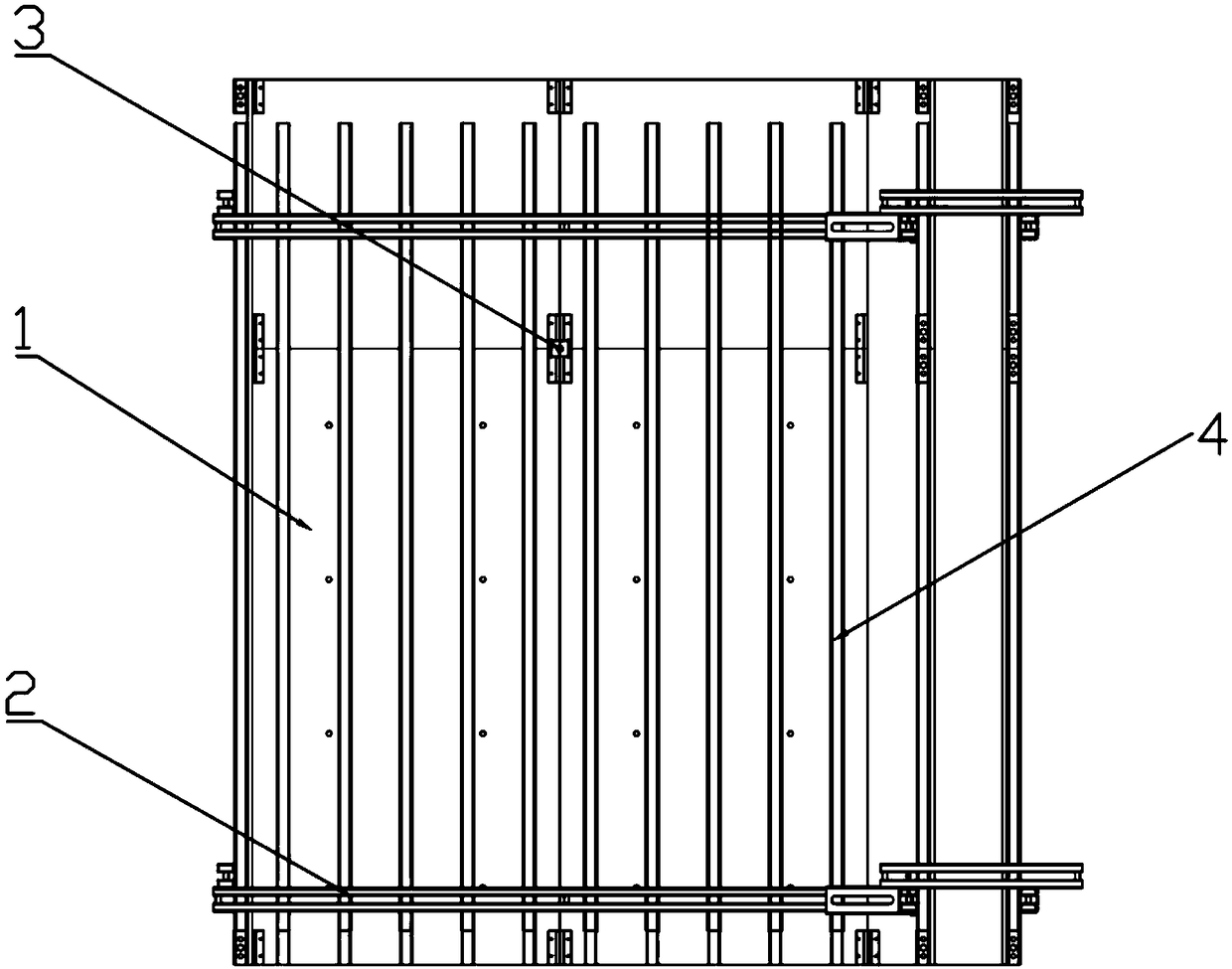

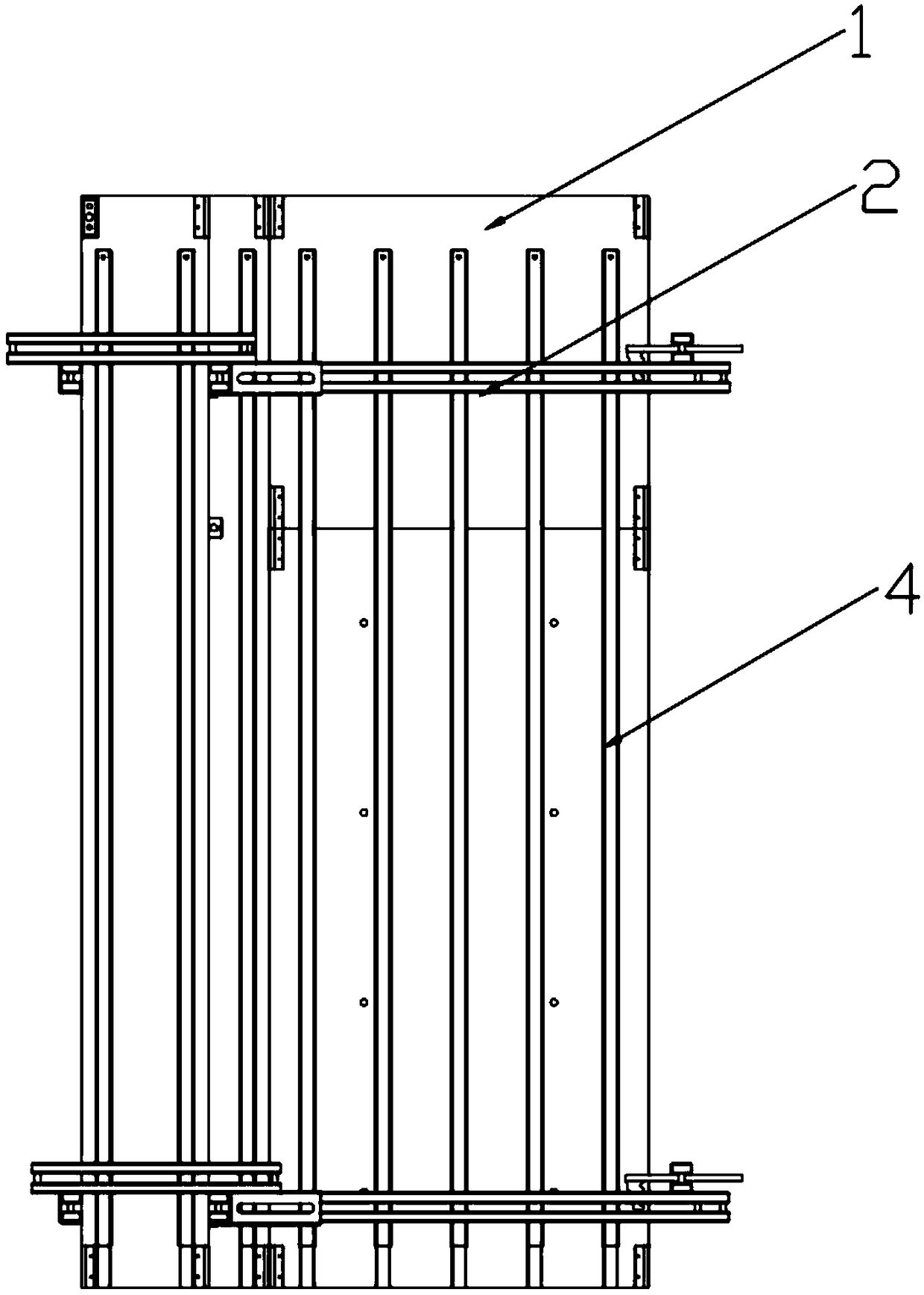

[0038] Example: see Figure 1 to Figure 13 , a shear wall casting mold provided in this embodiment, which includes a template 1 and several horizontal keels 2, the templates 1 are sequentially spliced to form the main body of the shear wall casting mold, and the shear wall casting mold The main body is provided with male corners and female corners, and the joints of the adjacent formworks 1 are provided with a connection assembly device 3 for fixedly connecting the adjacent formworks 1, and the horizontal keel 2 is cast around the shear wall The main body of the mold is set, and the horizontal keel 2 is fixedly connected with the template 1 .

[0039]In a preferred embodiment, the horizontal keel 2 includes a male corner connector 21, a female corner connector 22, two first main keels 23, two second main keels 24 and a main keel fixing member 25, the male The corner connectors 21 and the female corner connectors 22 are right-angle components, the male corner connectors 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com