Pre-baking anode carbon block

A prebaked anode and carbon block technology, which is applied in the field of aluminum electrolysis production, can solve the problems of poor flow effect and increase of conductor cross-sectional area, and achieve better effect, good fluidity and broad prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

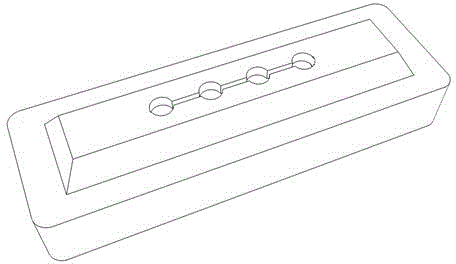

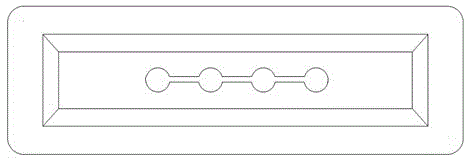

Image

Examples

Embodiment Construction

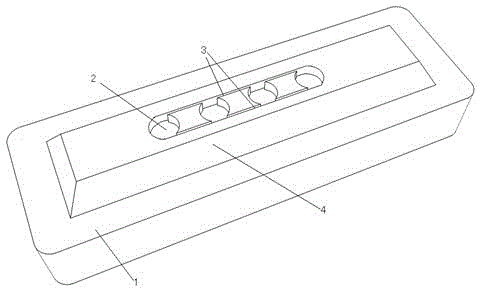

[0018] like image 3 and Figure 4 As shown, a prebaked anode carbon block includes a carbon block 1, and the upper end surface of the carbon collar 4 on the carbon block 1 has 6 equally spaced carbon bowls 2 with the same aperture arranged in a row, and the spacing is the same as the aperture of the carbon bowl 2 equal. There are two communication grooves 3 parallel to the length direction of the carbon block 1 between adjacent carbon bowls 2 . Every communication groove 3 is tangent to one end of two adjacent carbon bowls 2 at the same time, and the depth of communication groove 3 is the same as the depth of carbon bowl 2, and the width of communication groove 3 is 10% of the diameter of carbon bowl 2. The communication groove 3 connects the 6 carbon bowls 2 together. In this way, after the high-phosphorus iron is poured, not only the cross-sectional area of the conductor increases, but also a clamping force is formed on the carbon block between the two communication gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com