Light shield for contacting window making process and making process thereof

A technology of contact window and photomask, which is applied in the direction of original components, optics, and optomechanical equipment used for photomechanical processing, and can solve problems such as broken wires, poor coverage of pixel electrodes 110 steps, steepness, etc., and achieve the effect of increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

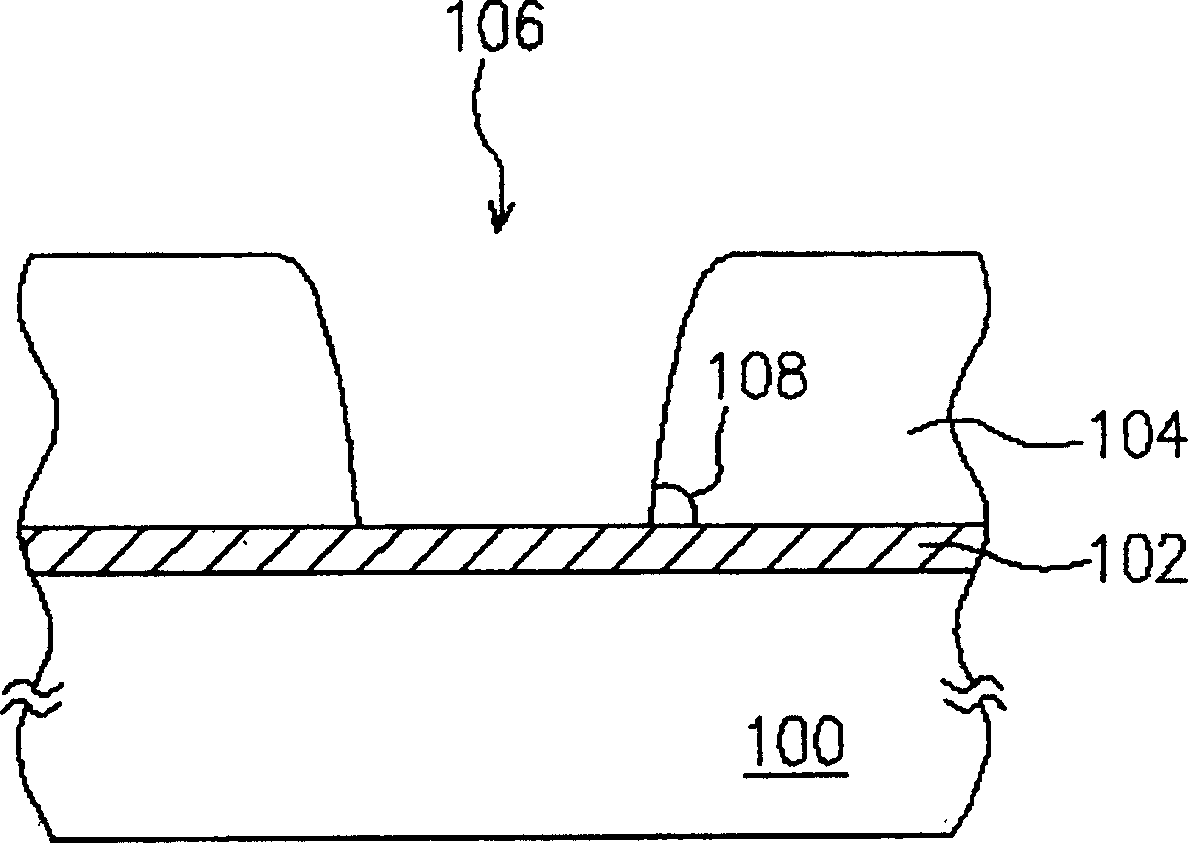

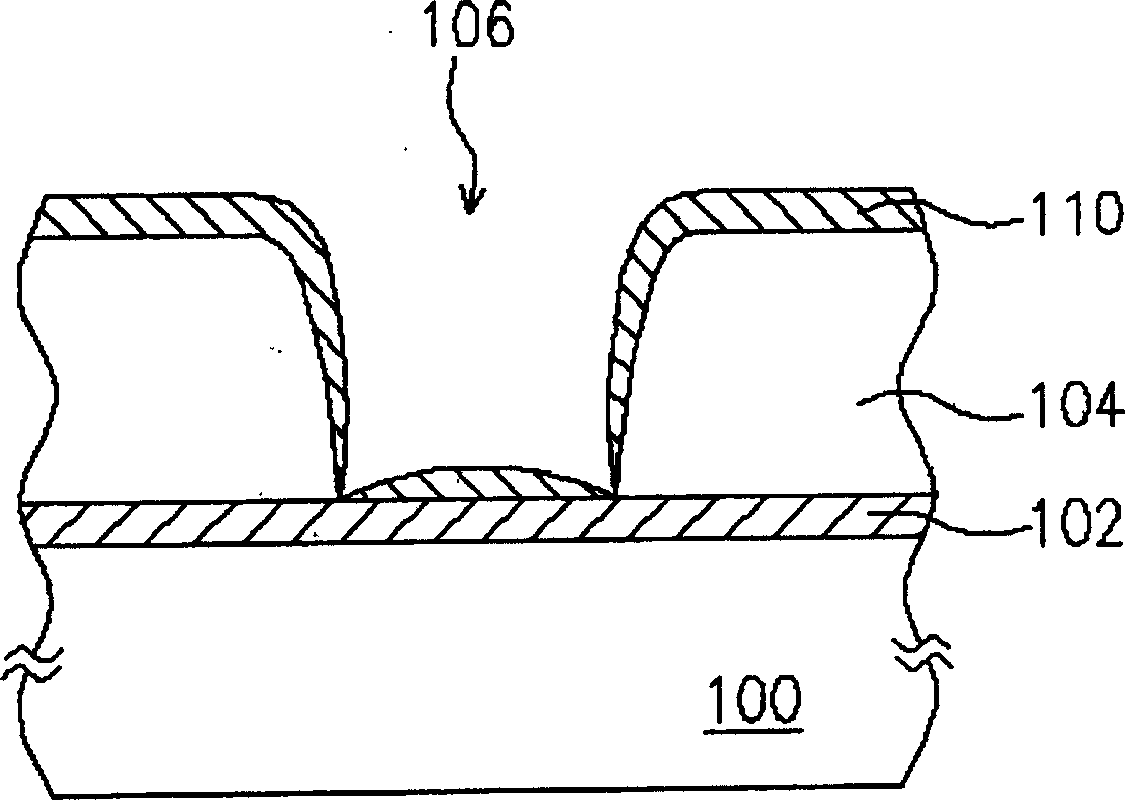

[0044] Such as Figure 2A to Figure 2E As shown, it shows a schematic cross-sectional view of the manufacturing process of the contact window according to a preferred embodiment of the present invention.

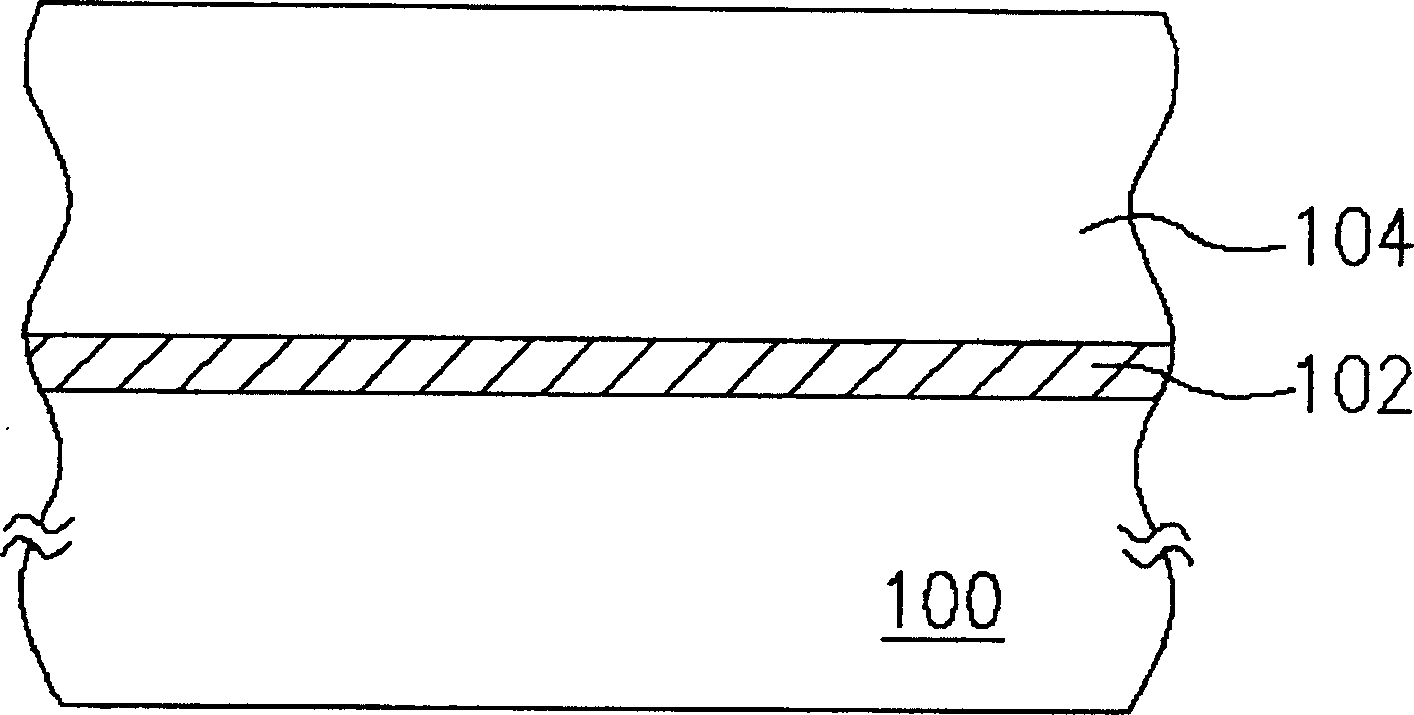

[0045] Please refer to Figure 2A , a substrate 100 is provided, a conductive layer 102 has been formed on the substrate 100 , and a dielectric layer 104 has been formed on the conductive layer 102 .

[0046] If the contact window process is applied in the liquid crystal display process, the conductive layer 102 is, for example, the second metal layer ( M2 ) in the TFT process, which can be the drain of the TFT or the upper electrode of the pixel storage capacitor. The dielectric layer 104 is, for example, a non-photosensitive inorganic dielectric material such as silicon nitride or silicon oxide, while in the manufacturing process of a liquid crystal display with a high aperture ratio, the dielectric layer 104 usually uses an organic photosensitive material (such as a phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com