Wire collecting device of electric wire and cable drawing machine

A wire take-up device, wire and cable technology, applied in the field of cables, can solve the problems of constant speed of take-up, easy loosening, copper wire breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

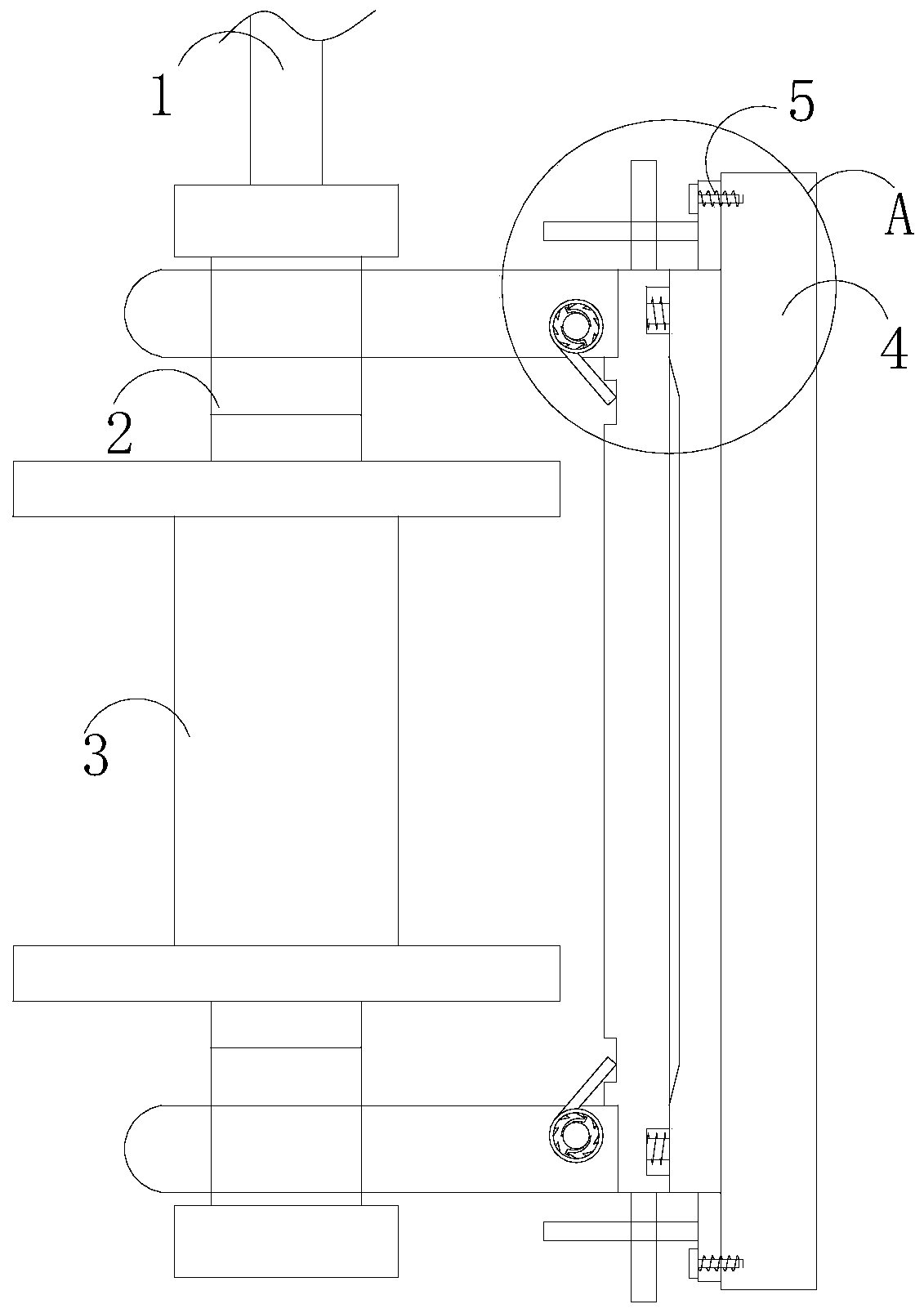

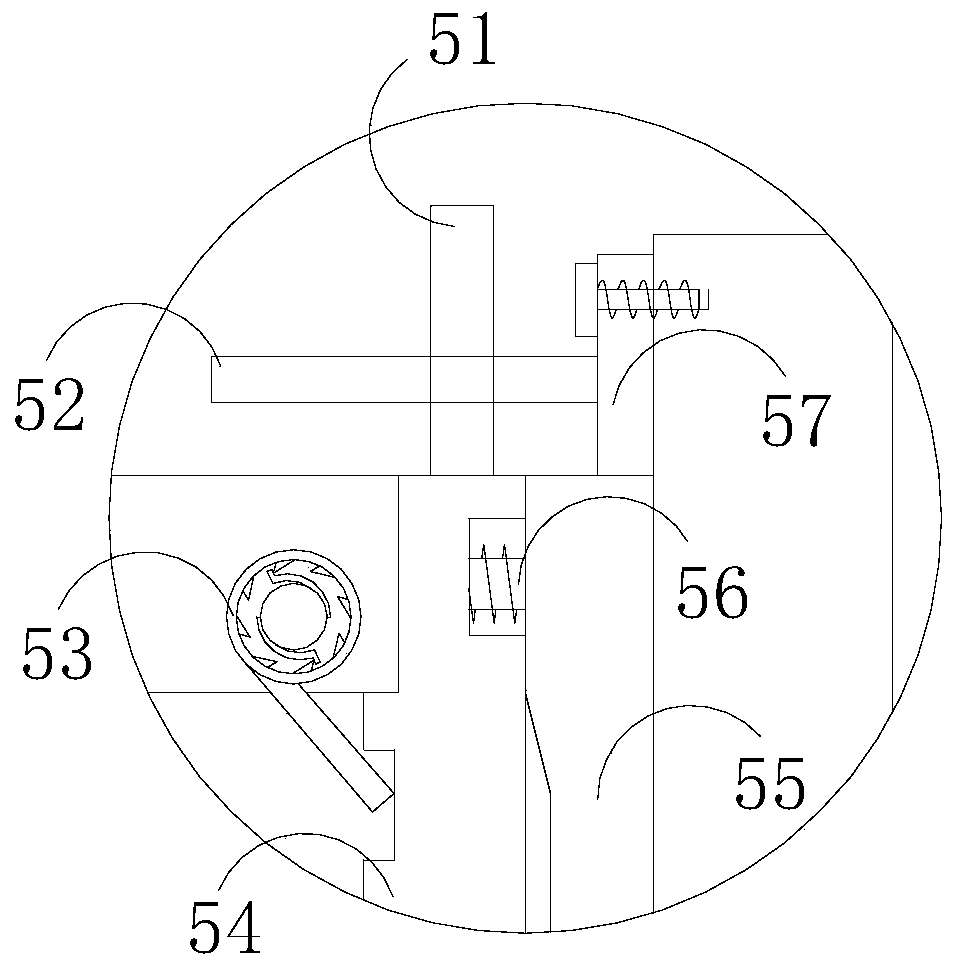

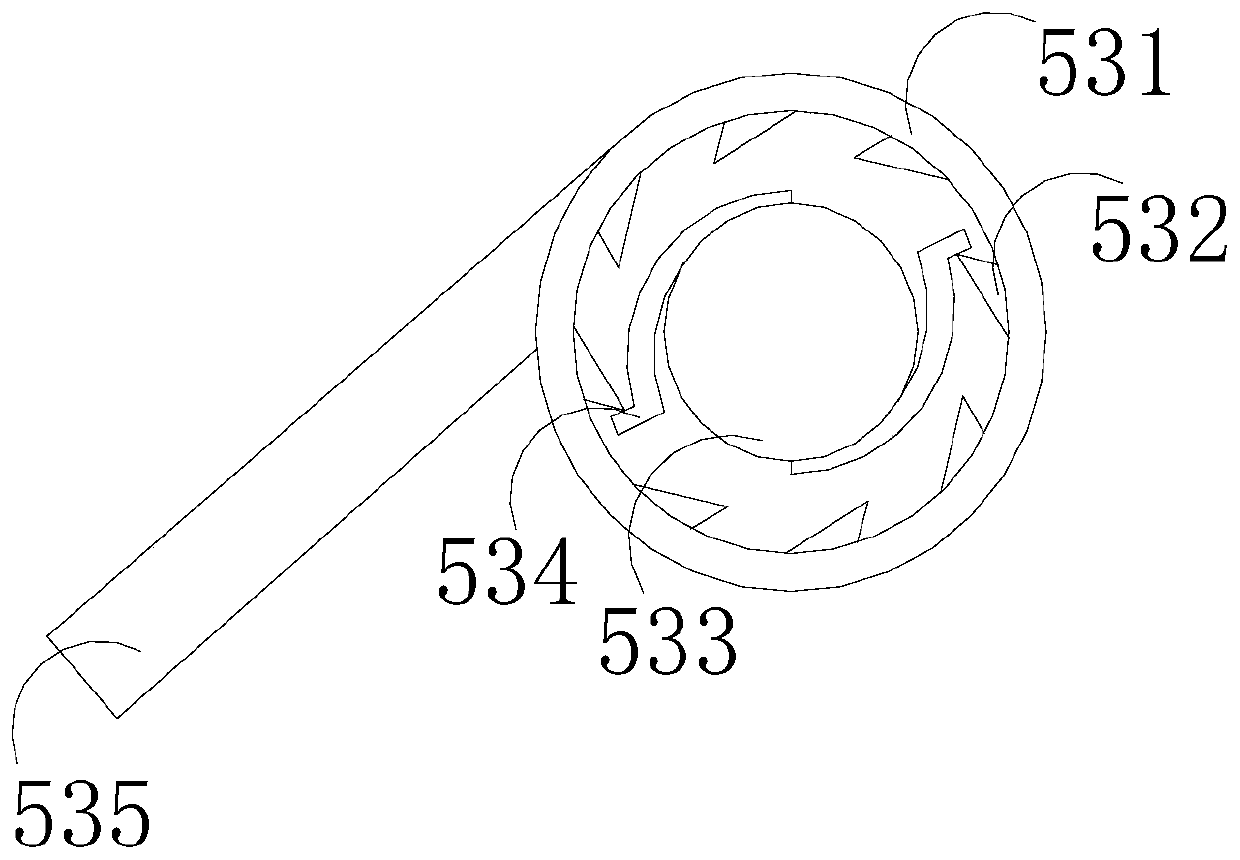

[0033] see Figure 1-Figure 11 , the present invention provides a wire take-up device of a wire drawing machine for wires and cables, the structure of which includes a drive shaft 1, a rotating tensioner 2, a wire storage wheel 3, a suspension bracket 4, and a tension adjustment structure 5, and the suspension bracket 4 consists of a panel The upper part is vertically welded with two support rods, and an I-shaped wire storage wheel 3 is movably installed between the tops of the two support rods of the suspension bracket 4, and the upper and lower ends of the wire storage wheel 3 are connected with the support rods to rotate Tensioner 2, one of which rotating tensioner 2 is also mechanically connected with drive shaft 1, the panel of the suspension bracket 4 next to the storage wheel 3 is provided with a tension adjustment structure 5, the tension adjustment structure 5 and the suspension bracket 4 Installed through the screw Quan activity.

[0034] The rotary tensioner 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com