Semi-feeding device of semi-feeding type harvester

A semi-feeding and harvesting machine technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high manufacturing precision requirements, complex structure, restricting the miniaturization of semi-feeding harvesters, etc., and achieve transmission efficiency. And the effect of high working reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

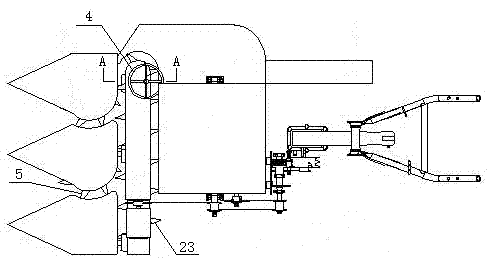

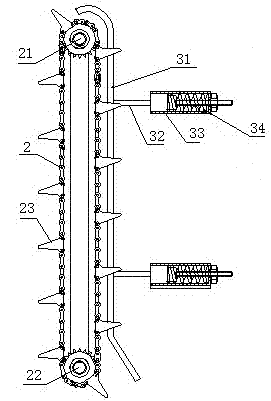

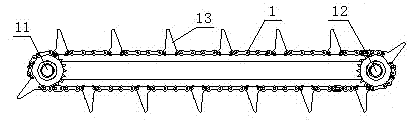

[0015] see Figure 1 to Figure 4 As shown, the semi-feeding device of the semi-feeding harvester includes a rice conveying mechanism positioned at the rear side of the Fuhe wheel 5, a clamping mechanism for clamping rice stalks, and a mechanism for sending rice ears into the threshing bin for threshing. The feeding mechanism and the straw discharge mechanism after threshing is completed. The rice conveying mechanism is a sprocket conveying mechanism, including a single guard chain 1 and a double guard chain 2 above the single guard chain. The single guard chain 1 is installed on the first driving sprocket 11 and the first driven sprocket 12 , and a plurality of first guard plates 13 arranged at intervals are arranged on the outer surface of the single guard chain 1 . The double guard chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com