Raw material formula design method of papermaking reconstituted tobacco leaves mixed with stem ends

A technology of reconstituted tobacco leaves and mixed extraction, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that subjective experience does not conform to the actual situation of reconstituted tobacco leaf production, and achieve scientific design methods, less land occupation, and low investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

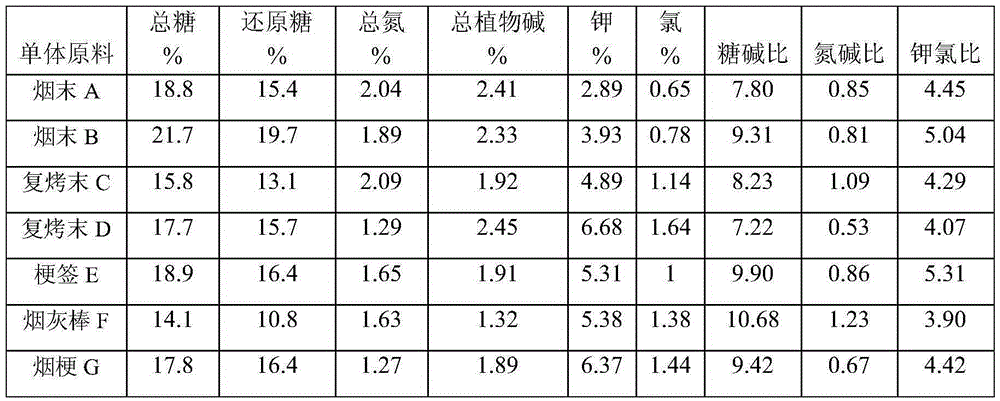

[0054] The design goal of this embodiment is a high-grade, strong-flavored reconstituted tobacco leaf, that is, the sensory evaluation score is >85. Tobacco powder monomer raw materials for use include 6 types: tobacco powder A, tobacco powder B, redrying powder C, redrying powder D, stem stick E, ash stick F, and tobacco stem raw material G.

[0055] Step 1: Determine the quality grade and category characteristics of the designed papermaking method reconstituted tobacco leaf product as a high-grade, strong-flavored papermaking method reconstituted tobacco leaf. High-grade means that the sensory quality evaluation score of the reconstituted tobacco leaf product is ≥ 85 points, and the aroma type means that the aroma type of the reconstituted tobacco leaf product is the aroma type. As a tobacco leaf raw material, it is suitable for the leaf group formula of the aroma type cigarette.

[0056] Step 2: Evaluate the quality of single raw materials such as tobacco powder and stems, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com