Auxiliary device for molding large-diameter and thin-walled cylinder

A thin-walled cylinder and auxiliary device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as failure to form a circle, sinking of the roll-out end, poor rigidity, etc., and achieve good force and small forming resistance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

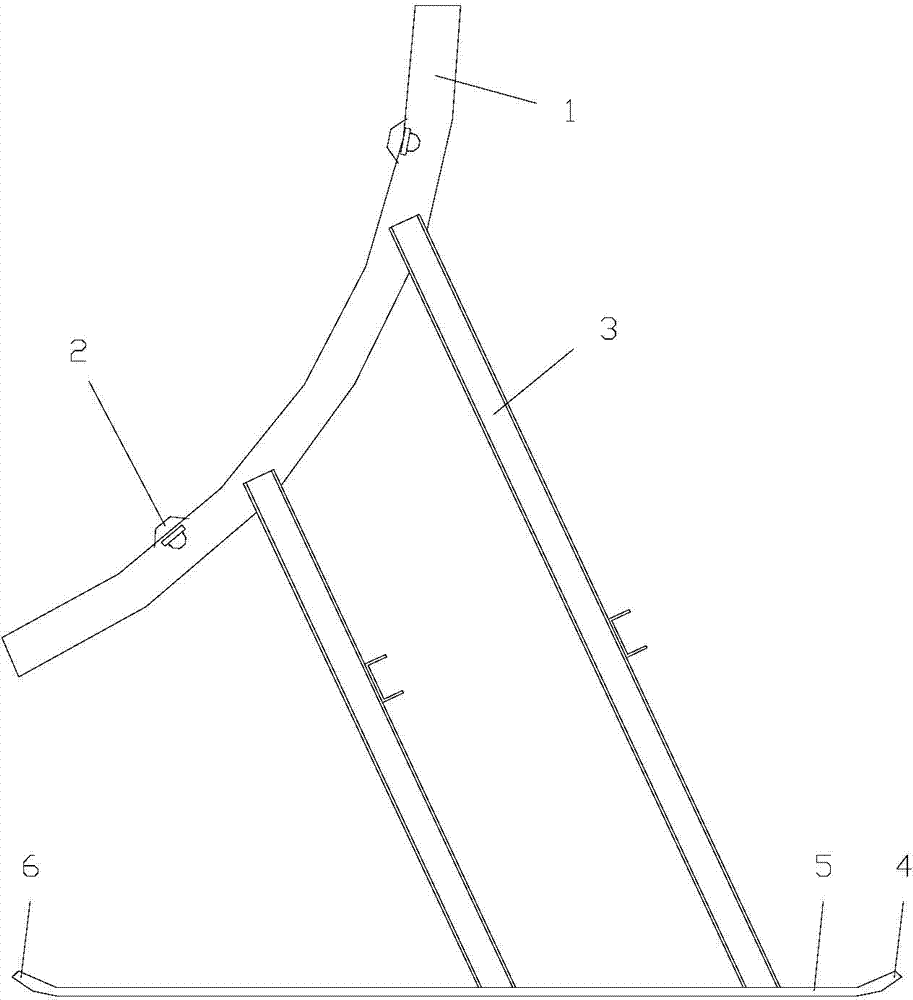

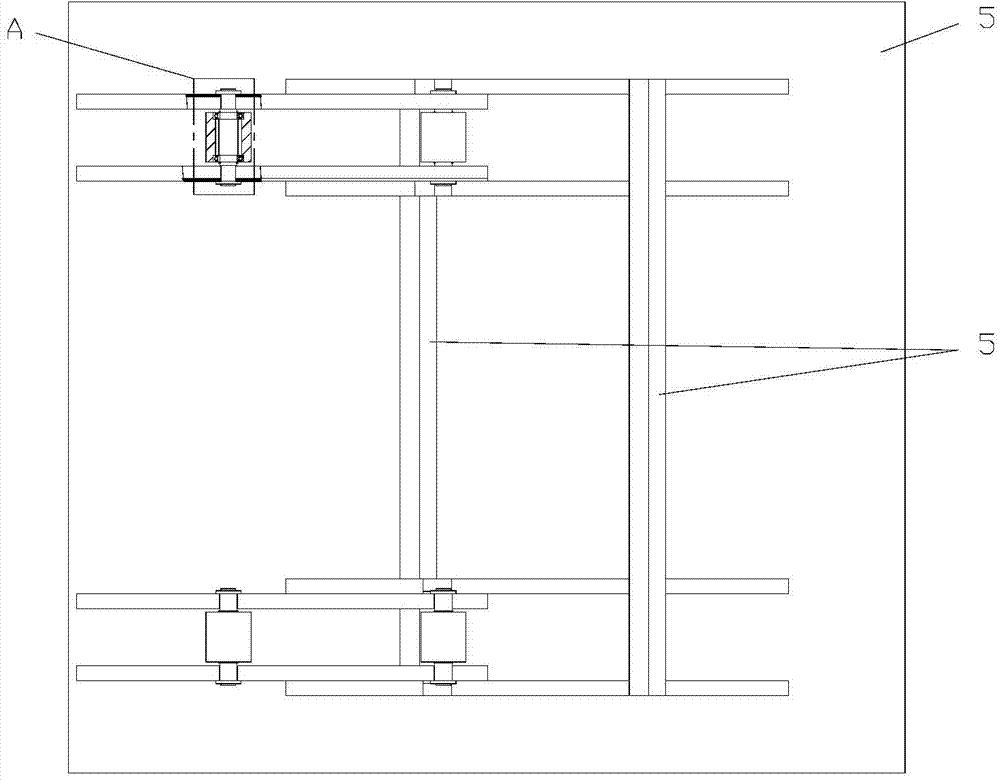

[0011] Such as figure 1 , 2 As shown, the arc-shaped bracket 1 is fixed to the bottom plate 5 through the braces 3 , and the inner arc surface of the arc-shaped bracket 1 is fixed with a roller 2 protruding from the inner arc surface of the arc-shaped bracket 1 .

[0012] Two sets of the structure of the arc-shaped bracket 1 and the diagonal brace 3 are fixed on the bottom plate 5, and the two sets are reinforced with a connecting piece 12.

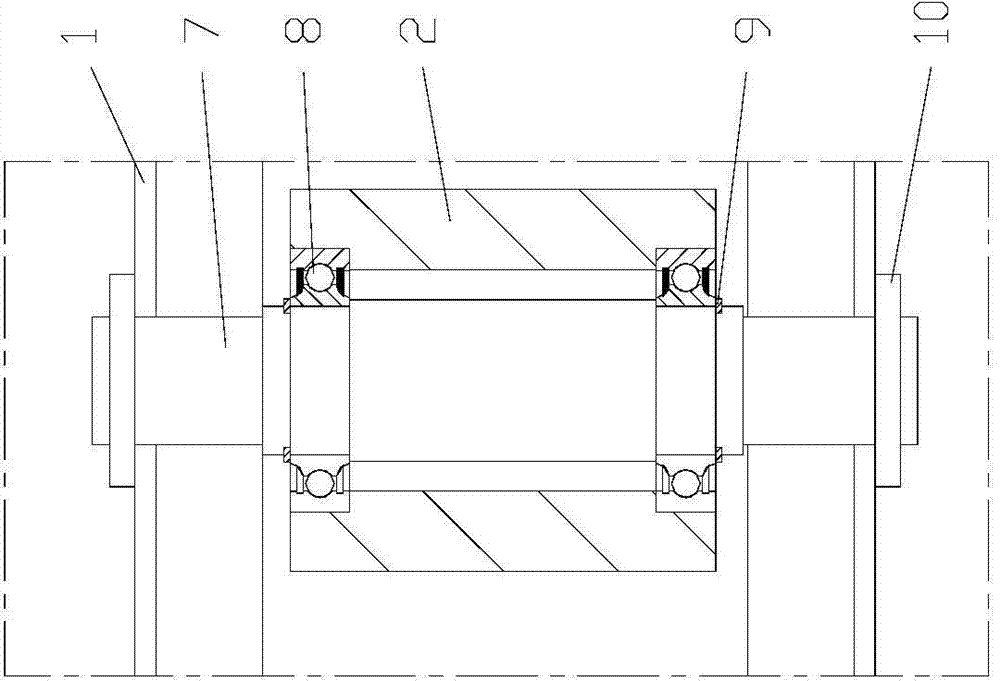

[0013] The roller 2 is fixed on the shaft 7 through the deep groove ball bearing 8 and the shaft end retaining ring 9 , the two ends of the shaft 7 are processed into a bow shape, and fixed on the arc bracket 1 through the pressing plate 10 . Prevent shaft 7 from rotating and roller 2 from moving axially to ensure smooth operation. Such as image 3 shown.

[0014] There is a notch on the arc-shaped bracket 1, and the shaft 7 is fixed on the notch. Easy to install and disassemble.

[0015] Both ends of the bottom plate 5 are bent int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com