Motor commutation head milling surface processing apparatus use method

A processing device and face milling technology, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., to achieve high positioning and processing accuracy, improve work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

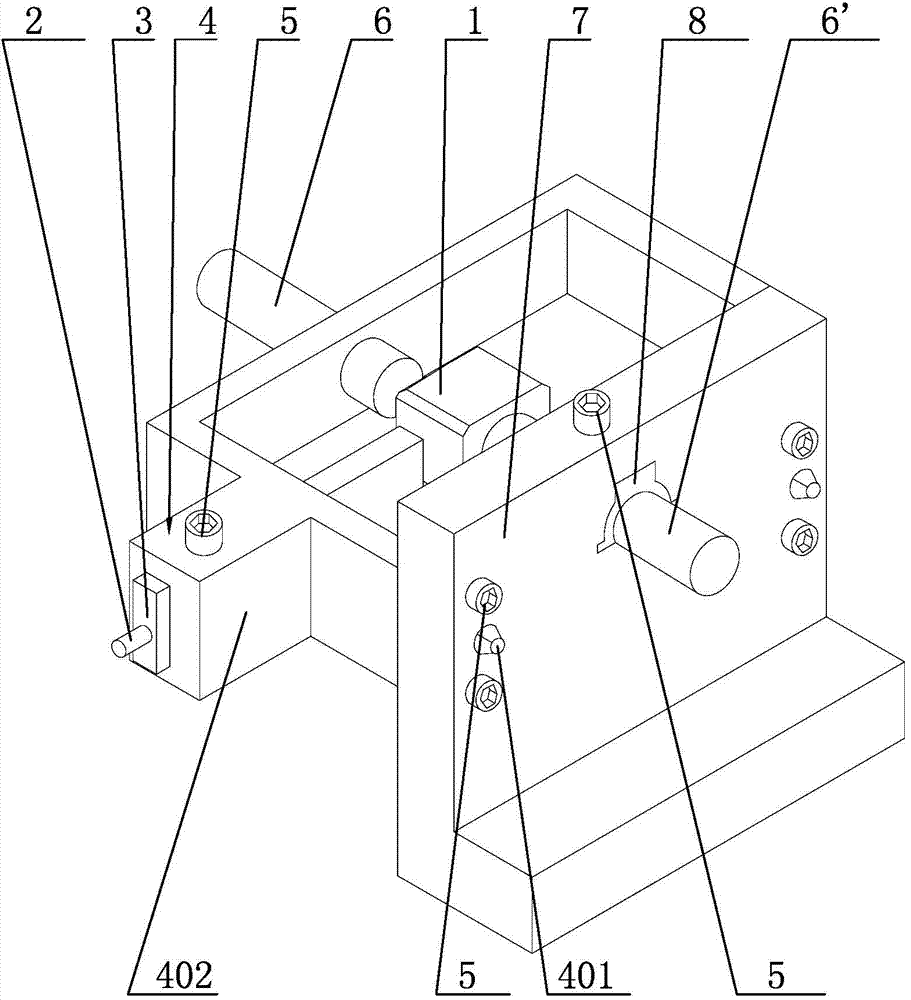

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

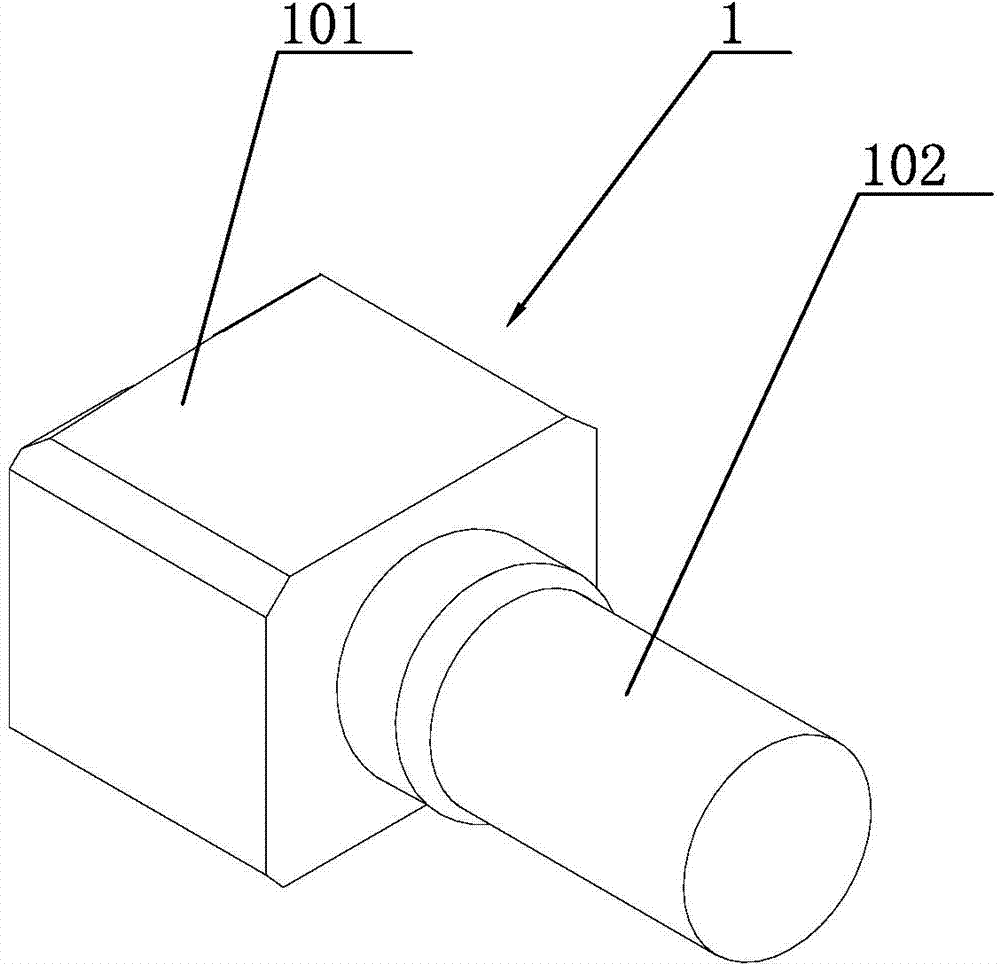

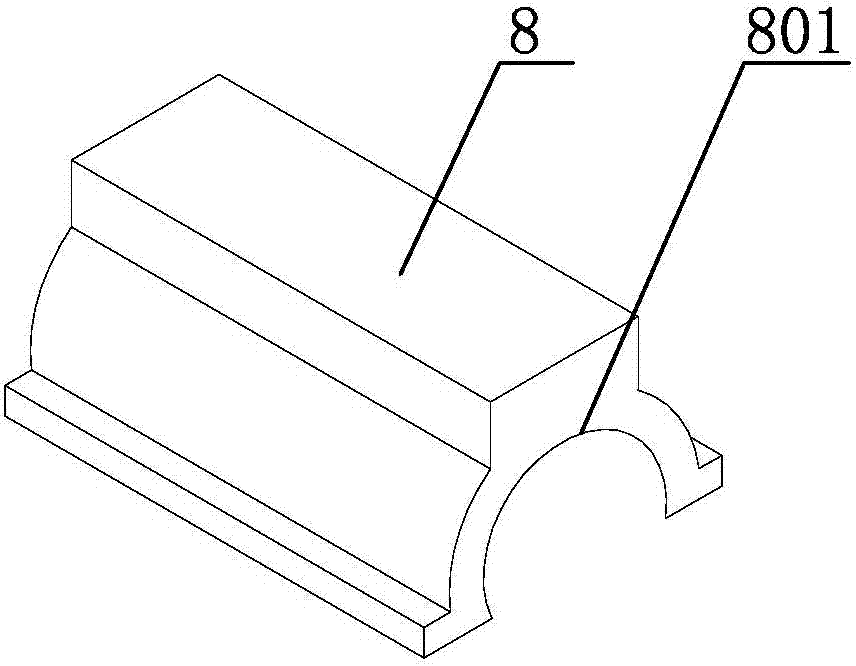

[0018] Such as figure 2 As shown, the method of using the motor reversing head milling processing device includes a mounting seat 4, and the two ends of the mounting seat 4 are provided with tapered bumps 401, and the mounting seat 4 is inserted into the fixed plate 7 through the above-mentioned tapered bumps 401 And fixedly connected by the lock nut 5, the fixed plate 7 is "L" shape. One side of the mounting base 4 extends outward to form a boss 402, and a through groove (not shown in the figure) is opened in the boss 402, and the positioning plate 3 is installed in the groove and locked by the lock nut 5. One side of the plate 3 also extends outwards to form a handle 2, which is cylindrical. On the side perpendicular to the boss 402 of the mounting seat 4, there is also a first positioning rod mounting hole, and the first positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com