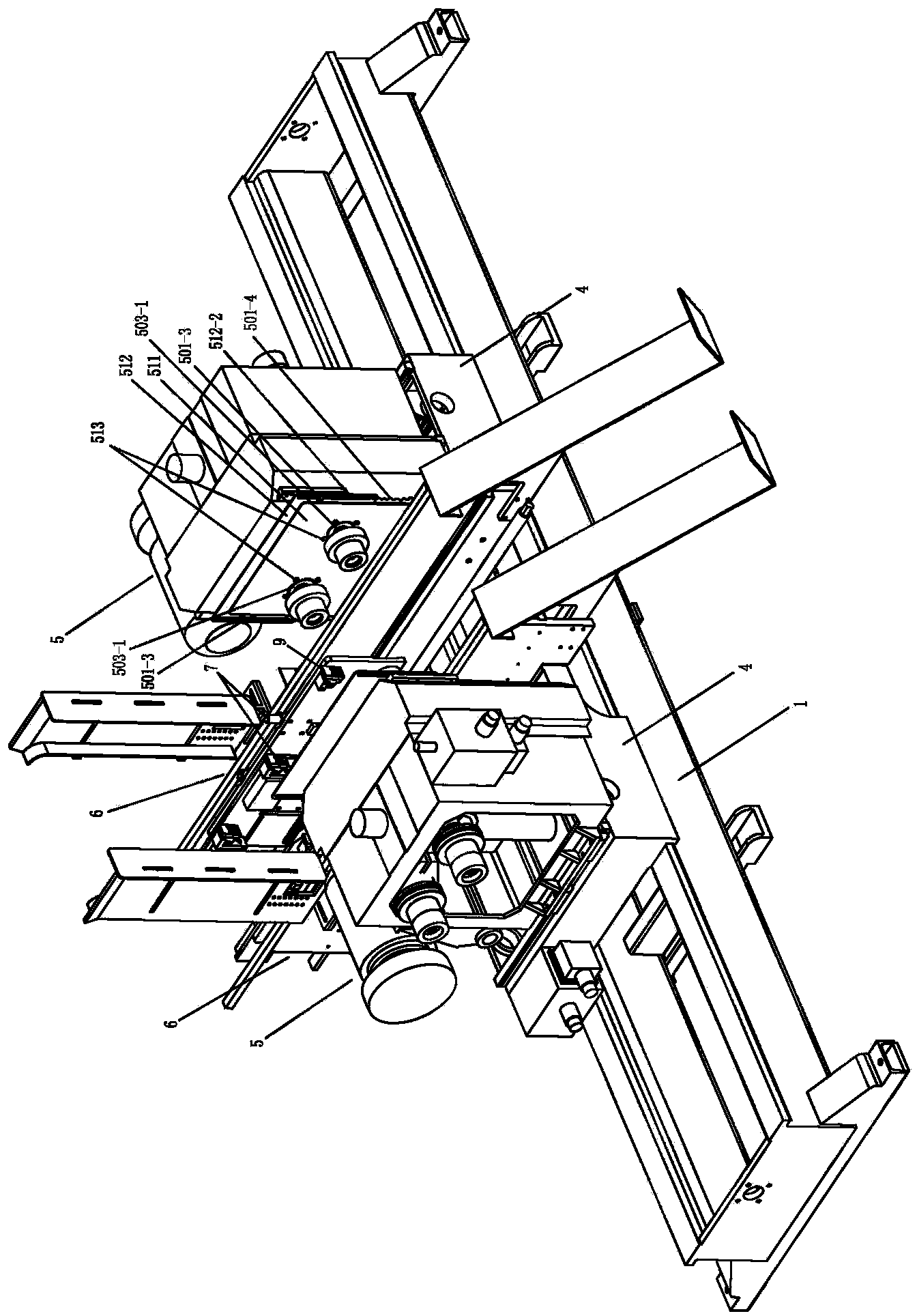

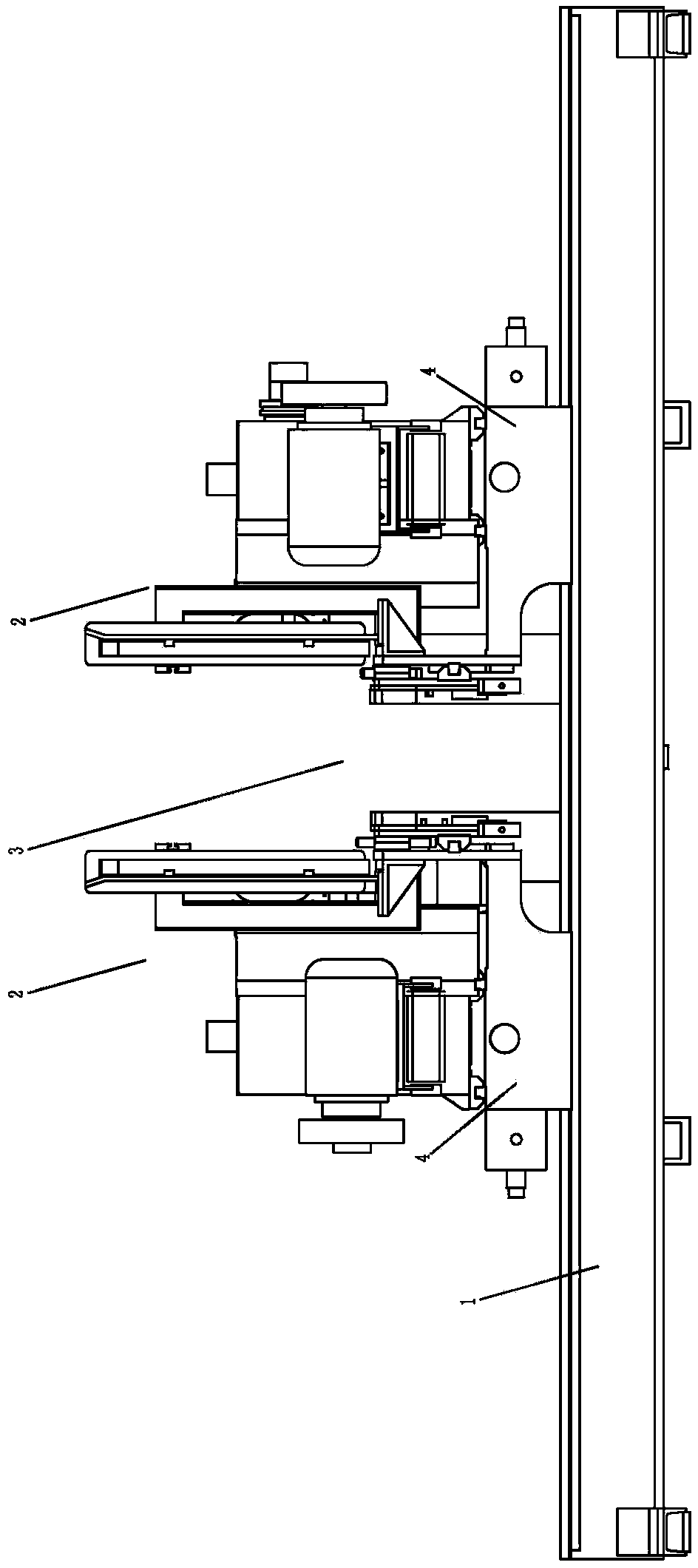

A CNC automatic double-end tenoning machine

A tenoning machine, double-ended technology, applied in tenon making devices, making tongues or mortises, etc., can solve the problems affecting the main shaft assembly, high manufacturing and maintenance costs, shortened service life of the main shaft assembly, etc., to achieve compact and beautiful products , save volume and space, and save maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

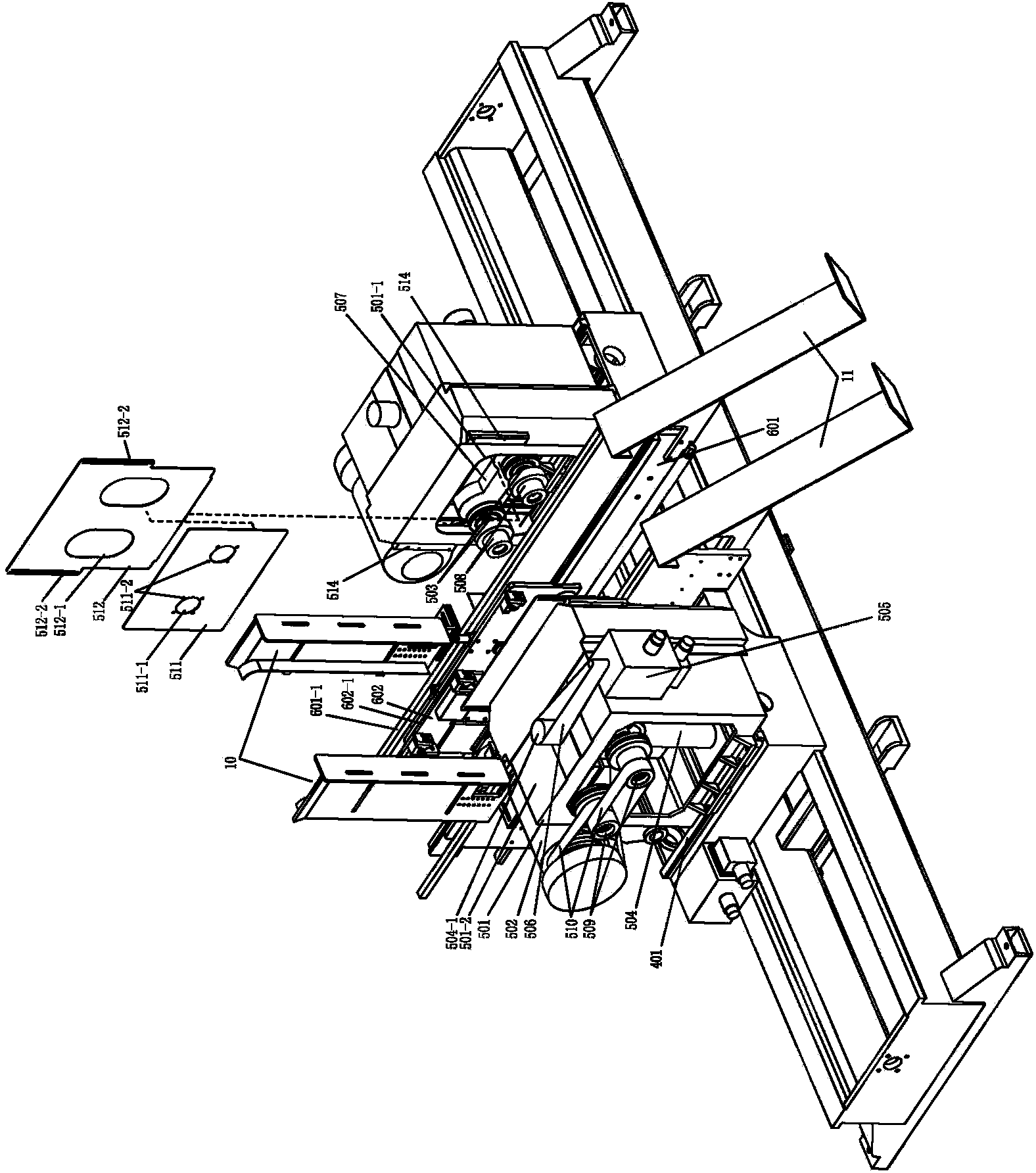

[0055] Guide pieces 501-3 are installed on both sides of the front end surface of the spindle housing 501, and sliding guide grooves 512-2 that slide up and down with the guide piece 501-3 are provided on both sides of the corresponding dustproof rear cover 512. The sliding guide grooves 512-2 A tension spring 501-4 is connected between the bottom end and the base 4; since the lifting range of the main shaft assembly 503 is not limited to the two main shaft guide grooves 512-1, that is, the main shaft assembly 503 may reach the main shaft guide groove when it is rising or falling. After the two ends of 512-1 continue to rise or fall, at this time, the main shaft assembly 503 drives the dustproof front cover 511 and the dustproof rear cover 512 up and down at the same time, so in order to ensure the stability of the dustproof rear cover 512 lifting, through the anti The sliding guide grooves 512-2 on both sides of the dust-proof back cover 512 cooperate with the guides 501-3 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com