Machining center clamp and machining center

A fixture and jaw technology, which is applied in the field of processing machine tools, can solve the problems of relative movement between the workpiece and the fixture, slow clamping speed of the fixture, and reduced machining accuracy, and achieve the effects of convenient tool setting, improved machining efficiency, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

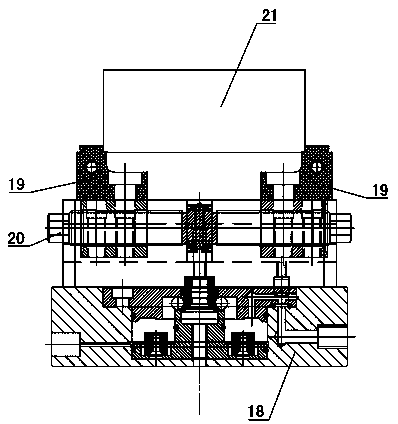

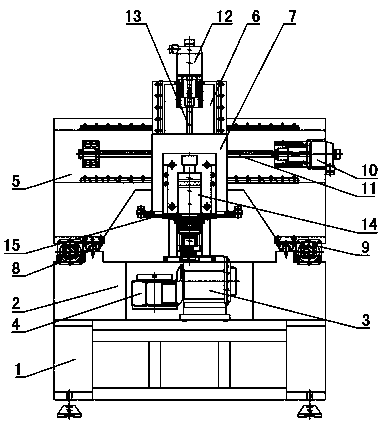

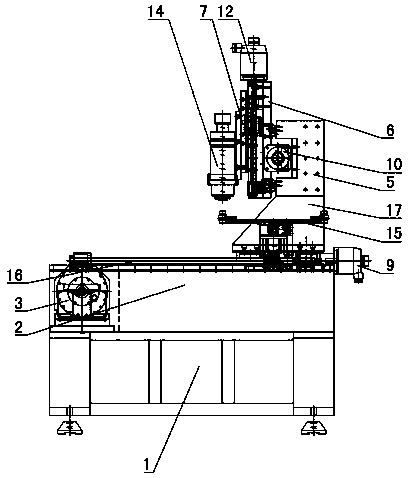

[0024] Figure 1~9 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~9 The present invention will be further described.

[0025] A clamp for a machining center, including a clamp base 18, clamp jaws 19 and clamp screw 20, two clamp jaws 19 are arranged symmetrically on both sides of the clamp base 18, and the clamp jaws 19 are slidably installed on the upper side of the clamp base 18 , the inner side of the upper part of each jaw 19 is provided with a relief port, thereby forming a loading part on the upper part of the jaw 19, the jaw screw 20 is rotatably installed on the clamp base 18, and the two ends of the jaw screw 20 are respectively connected to The jaws 19 on the corresponding side are threaded, and the jaw screw 20 is connected with a clamping power device that drives it to rotate. The jaw lead screw 20 of the fixture of this machining center simultaneously drives the two jaws 19 to move in opposite directions synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com