Electrically-driven labor-input type casing milling and fishing combined tool

A combined tool and casing milling technology, which is applied in the direction of wellbore/well components, earthwork drilling, etc., can solve the problems of high operating costs, sand production in the wellbore, sand accumulation in the restrictor, etc., and achieve the effect of reducing construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the present invention and actual conditions.

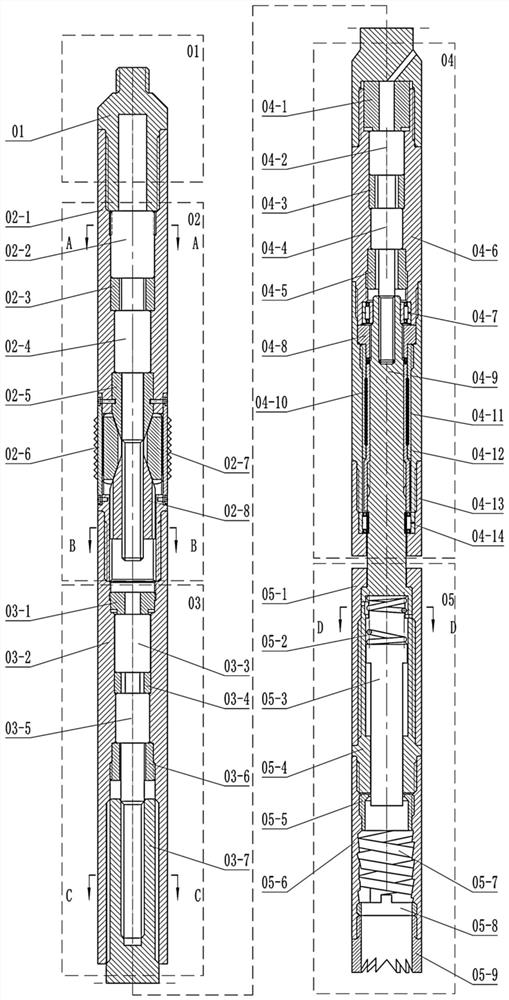

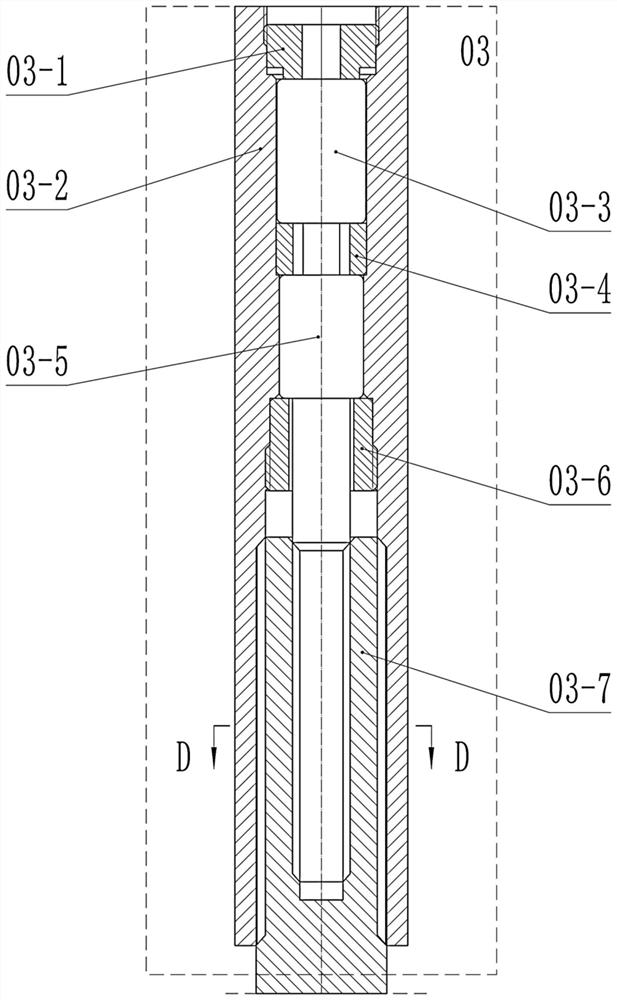

[0025] Such as figure 1 As shown, the present invention provides an electric-driven cast-in type casing milling and fishing combination tool, which includes an upper joint 01, an anchoring part 02, an axial feed part 03, a power part 04 and a casing milling and fishing part 05; the upper joint 01 is connected to the cable joint; the lower part of the upper joint 01 is threaded to the upper part of the anchoring part 02; the lower part of the anchoring part 02 is threaded to the upper part of the axial feed part 03; the lower part of the axial feed part 03 is connected to The upper part of the power part 04 is threaded; the lower part of the power part 04 and the upper part of the milling and fishing part 05 are threaded.

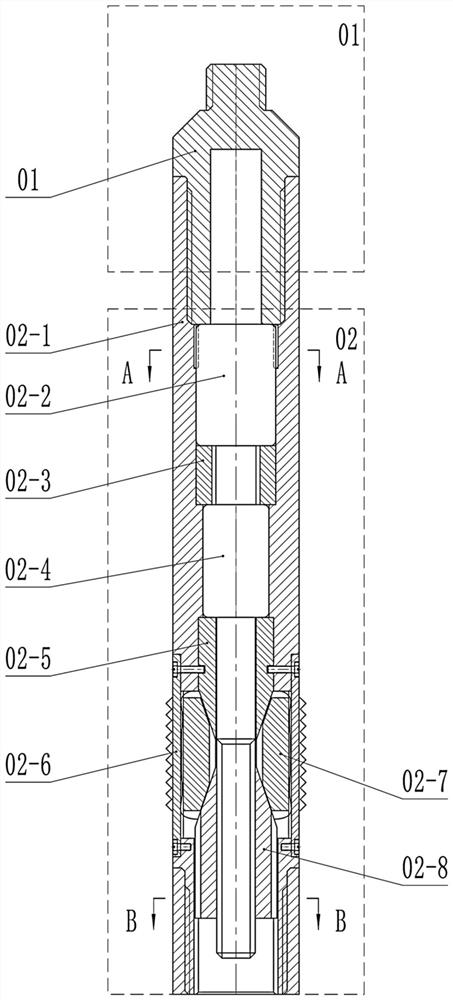

[0026] Such as figure 1 , 2, 6, and 7, the anchoring part 02 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com